Drying Of Kaolin Production Process

washed kaolin production process

washed kaolin production process. Washed kaolin production line washed kaolin production process washed kaolin is got from the wet process which includes three stages that is the mineral preparation mineral dressing and processing mineral preparation consists of work of burdening crushing stirring pulp and so on and the impact crusher is used in the secondary chat online

kaolin production process

The kaolin clay powder production process features the separation of kaolin from quartz and feldspar by dry and wet processing. read more. kaolin clay britannica. kaolin kaolin, soft white clay that is an essential ingredient in the manufacture of china and porcelain and is widely used in the making of paper, rubber, paint . read .

process of produsing kaolin

process of produsing kaolin Introduction. drying of kaolin production process. Clay Processing. Drying Of Kaolin Production Process Gold Ore Crusher, Home products drying of kaolin production process gold ore crusher mobile crushing plant stationary crushing plant grinding mill vsi6s vertical shaft impact crusher c6x series jaw crusher ci5x series impact crushers mtwseries .

A REVIEW OF ENVIRONMENTAL CONCERNS Kaolin Clay Mining .

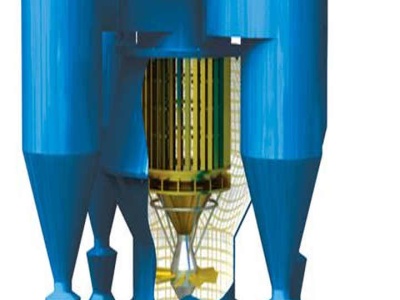

Production figures reported in millions of short tons, value reported in millions of dollars. Source: Bureau of Mines. Air Flotation Process Air flotation is primarily used for the production of filler clays. The process consists principally of crushing, drying, and pulverizing the crude ore, and

Process Flow Of Waterwashed Kaolin Production

· Process Flow Of Waterwashed Kaolin Production. Kaolin is a nonmetallic mineral, a kind of clay and clay rock dominated by kaolinite clay minerals. Because it is white and delie, it is also called Baiyun Earth, and it is named after Gaoling Village, Jingde Town, Jiangxi Province. The pure kaolin is white, fine, soft, and soft.

Washed kaolin production process

Washed kaolin production process. Washed kaolin is produced by coarsening, slurring, sieving, grinding, centrifuging, grading, chemical and possibly magnetic treatment, concentration and drying of coarse clay to achieve the desired purity, particle size and brightness. And residue. The washed kaolin is an aqueous clay that retains 14% of the ...

Refractory Manufacturing

The processed raw material then may be drymixed with other minerals and chemical compounds, packaged, and shipped as product. All of these processes are not required for some refractory products. Forming consists of mixing the raw materials and forming them into the desired shapes. This process frequently occurs under wet or moist conditions. Firing involves heating the refractory .

kaolin production process

Production Process Kaolin. Polishing During this process the surface of tiles is being polished by special brushes to achieve one of several possible looks Matt or honed tiles are also polished but to a lower level than polished tiles Two layers of antidust nano layers are added to avoid impurities in the glaze of the tile . More. Kaolinite Processing Equipment, Process Flow, Cases There are ...

Facts on Spray Drying: Viable Solution ...

· Facts on Spray Drying: Viable Solution for Georgia's Kaolin Industry. Spray drying is the most widely used industrial process involving particle formation coupled with drying. It's well suited for continuous largescale production of dry solids in powder, granulate, or agglomerate form from solutions, emulsions, and pumpable dispersions.

kaolin drying process

dry and wet process for kaolin kaolin equipment suppliers Development of kaolin production reserves and processing in the Dec 2 2017 The separated waste products... drying process for kaolin Know More. XSD Sand Washer The efficient sand washing machine of XSD series is a kind of cleaning equipment of international advanced level for sand and slag pellets developed on the basis of .

Drying moist filter cake

dry finished product. Examples are: • Titanium dioxide and titanium oxide hydrate • Magnesium hydroxide and oxide • Aluminium oxide and hydroxide • Strontium chromate • Barium chromate • Kaolin The suspended solid material in the suspensions that are to be filtered usually consists of extremely finely grained primary particles in the micrometre or even nanometre range. This leads ...

kaolin production process

The kaolin clay powder production process features the separation of kaolin from quartz and feldspar by dry and wet processing. read more. kaolin clay britannica. kaolin kaolin, soft white clay that is an essential ingredient in the manufacture of china and porcelain and is widely used in the making of paper, rubber, paint . read . Read More ; Kaolinite Wikipedia. Kaolinite (/ ˈ k eɪ. ə ...

Our process

Before kaolin can be put to good use, it has to go through several production processes. First, raw kaolin has to be extracted and processed using the wet production method which involves dissolving, segregation, filtering, dewatering and drying operations.

Kaolinite

Kaolinite (/ ˈ k eɪ. ə. l ɪ ˌ n aɪ t / KAYəlihnyte) is a clay mineral, with the chemical composition Al 2 Si 2 O 5 is an important industrial is a layered silie mineral, with one tetrahedral sheet of silica (SiO 4) linked through oxygen atoms to one octahedral sheet of alumina (AlO 6) octahedra. Rocks that are rich in kaolinite are known as kaolin (/ ˈ k eɪ. ə ...

the production process of kaolin in ghana

the production process of kaolin in ghana; the production process of kaolin in ghana . Kaolin clay Britannica,Mineral Information Institute When kaolin is mixed with water in the range of 20 to 35 percent it becomes plastic ie it can be molded under pressure and the shape is retained after the pressure is removed With larger percentages of water the kaolin forms a slurry or watery suspension ...

Kaolin clay processing

In a process for producing white fineparticle size calcined kaolin pigment particles which comprises subjecting impure crude hydrated kaolin to wet processing in a manner such as to provide a dilute deflocculated fluid suspension in water of a fine particle size fraction of kaolin clay, dewatering said suspension by spray drying or by filtration followed by spray drying and provide dry ...

Kaolin Production Process

kaolin production process. Kaolin processing technology appliions equipment the production process features the separation of kaolin from quartz and feldspar by dry and wet processing the plant equipment consists mainly of mining equipment, crusher, roller with classifier, attritioning cells, hydrocyclones, thickener, bleaching equipment, filter press, dryerpulverizer, bagging.

Fluid Bed Dryers design and manufacturing | Tema Process

TEMA Process is a specialised design and manufacturing company for Fluid Bed Systems for drying of minerals, chemicals, food, feed, biomass, etc. The TEMA Fluid Bed can be applied not only for drying, but also for cooling, roasting, torrefaction, puffing, blanching, stripping, spices and herbs sterilisation and pasteurisation and calcining.

Latest Posts

- مشروع فصل المواد باستخدام الحزام الناقل

- الكرة مطحنة الكرات المصنعين

- عملية مطحنة الكرة وقوات الدفاع الشعبي صيانة

- تستخدم آلات الفك الثقيلة

- تستخدم كسارة الحجر بيع الجزائر

- المعدات ومناجم الذهب في الجزائر

- مصانع وعمليات تعبئة الإسمنت

- الفولاذ إعادة الدرفلة مورد آلة

- معدات محطم للخرسانة في مصر

- مطحنة الكرة لطحن صخور الفوسفات

- تأجير كسارات الصخور الصغيرة مصر

- آلة طحن عمودي العالمي

- يوفر سحق الفرز

- مطحنة للبيع في فيجي

- الصناعية الكرة تطبيق مطحنة

- Coffe Grinding Machines Industrial Type

- Trachyte M Choire Concasseur

- Ramond Mill For Sale From Xsm

- Greenville Quarries Ky

- Free Gold Gravity Seperation Plants

- Crusher Manufacturerer In Japan

- Traders Of Minning Crushers Sorrounding Of Delhi

- Crusher B B Morocco

- Fo Rmulch And Crushed Stone

- Stone Production Line Stone Crusher

- Crushing Bricks Machines

- Ex Grinding Equipment Johannesburg

- Sandblasting Equipment In Ontario Canada

- Graphite Black Beneficiation Plant

- Separator Mobile Gold Plant For Alluvial Gold Mining