Coal Pulverizer Power Plant

Dynamic Modelling and Simulation of Coal Pulverizer ...

· As the megawatt power output of thermal power generating plant is directly influenced by the coal being fired into the boiler, it is necessary to study the dynamic behaviour of the model as their poor dynamic performance causes a slow megawatt ramp up or ramp down rate and also causes shutdown of plant in some cases. In view of more and more penetration of renewable energy in the .

Pulverizer Plant Different Pdf

Coal mill pulverizer in thermal power plants 15 Mill Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is admitted into the boiler furnace for combustion The mill output can be easily varied as per the turndown ratio from its minimum to maximum load. Different Types Of Coal Pulverizers Bryan D . Types of Boiler Coal Pulverizers Scribd Read ...

Coal Pulverizer and Coal Crusher Reliability | Mobil

Coal pulverizers/crushers Industries • Power generating stations Key appliions • Gears — worm and helical, bevel combinations • Roller element bearings Challenge: Coal pulverizer reliability. Repairs and even routine maintenance are timeconsuming and costly due to difficult operating conditions. Operating temperatures can be high and coal dust is typically present. Careful ...

A Comparison of Three Types of Coal Pulverizers

A COMPARISON OF THREE TYPES OF COAL PULVERIZERS by BENSON, Senior Engineer Fuel Burning Product Development and PENTERSON, Manager Fuel Burning Product Development RILEY STOKER CORPORATION WORCESTER, MASSACHUSETTS ABSTRACT In a continuing effort to offer the power industry a wide variety of coal handling equipment, Riley Stoker Corporation has .

power plant coal mill pulverizer

Coal Mill Pulverizer In Thermal Power Plants. Nov 17, 2012 2 2 Coal pulverizermill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill . Get Price

Mitsubishi Power | MHPS Receives Order to Refurbish ...

· Core Component of Coal Pulverizer. Yokohama, February 8, 2016 Mitsubishi Hitachi Power Systems, Ltd. (MHPS) has received an order to refurbish eight units at the Ulaanbaatar Thermal Power Plant, State Owned Stock Company, which is Mongolia's largest coalfired thermal power generation plant.

cement plant coal mill pulverizer

· pulverizer coal mill in power plantcuppenpsychologen . Pulverizer cement millscoal mill pulverizers used in cement mills power plants plants coal alstom power plant coal grinder pulverizer 25700 Rock Dec 13 2011 Ball tube mills are either pressurized or suction type In the pressurized type the hot primary. Read More; pulverizercementreciproor

coal fired power plant pulverizer

Conventional coalfired power plant encyclopedia article ... 21 Oct 2013 ... A 500 MW coalfired power plant will have about six such pulverizers, five of which .

Reducing wear and extending gear life in a coal pulverizer ...

A coalfired power plant operating in the western was experiencing short gearbox life in their coal pulverizing operation. After an annual gearbox inspection, oil analysis results indied that the AGMA 6EP (ISO 320) gear oil recommended by the original equipment manufacturer failed to provide adequate lubriion and protection based on oil analysis results and gearbox inspection after ...

coal mill pulverizers in power plants 1

coal mill pulverizers in power plants 1; coal mill pulverizers in power plants 1. farming industrial and mining equipment suppliers zimbabwe; thesis about quarry in filipino; single layer vibrating screens in kabul; mesh sizes of a grinding machine; bl sbm sr tracked cone crusher voltas ltd;

Coal Fired Power Plant Pulverizer Gear Coupling Failure ...

· The coal pulverizer is critical equipment, if it is not blowing coal, it is not generating power; needless to say, would you rather have your pulverizer blow coal or blow off your money?. The disc coupling solution reduced the maintenance nightmare, and the plant has been experiencing success for more than a year with the original installation. Plant management approved the proposal to convert ...

Coal Bunker

Dipak K. Sarkar, in Thermal Power Plant, 2015. Pulverizer System Design. NFPA 85 recommends the pulverizer system arrangement should be such as to provide only one direction of flow,, from the points of entrance of fuel and air to the points of discharge. The system should be designed to resist the passage of air and gas from the pulverizer through the coal feeder into the coal bunker ...

Fire Detection Methods for Coal Pulverizer ...

The studies showed that there is an emergence of low rank, high reactive coals as a base fuel for power plants which is resulting in an increase in pulverizer system fires. Also, the EPRI study concluded that reducing the frequency of fires would reduce the risk of coal dust explosions. Unfor tunately, less than 15 percent of the power plants have adequate fire detection systems for coal ...

Coal Pulverizer Monitoring and Analysis: A Case Study ...

· Onsite tests were conducted on a CE843RS pulverizer in a power plant. Volume Subject Area: Operations, Maintenance, Reliability, Availability and Maintainability. Topics: Coal, Maintenance, Modeling, Data acquisition systems, Design, Energy generation, Flow (Dynamics), Grinding, Power stations, Pressure drop, Rollers, Temperature measurement, Vibration, Wear. This content is only .

Leading Coal Pulverizers and Mills » Babcock Wilcox

Reliable coal pulverizer performance is essential for sustained fullload operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW.. BW's pulverizers, found at power stations throughout the world.

Boiler Mill and Coal Pulverizer Performance | GE Steam Power

Our Boiler Mill and Coal Pulverizer Service Solutions help you make the most of your mill's operational efficiency. Learn more about GE's boiler mill services. GE Steam Power. Market Segments . Market segments. Nuclear turbine island Coal power plant services Industrial plant services Featured content. Expert insights Customer success stories The Power of Yes in action Catalogs Products ...

Pulverised Coal

Pulverized coal power plants are broken down into four egories, with operating temperatures and pressures as a function of the steam temperature and pressure: •. Subcritical pulverized coal (SubCPC) plants, below the critical point of water (540°C and 170–220 bar), have an operating efficiency <38%. •.

From pellets to power: Inside North America's first power ...

· Instead of being decommissioned with the other coalfired plants, in 2014, the Atikokan, Ont., generating station became North America's first plant to be converted from coal to biomass. Built in 1985, the plant was still considered fairly new with plenty of service life remaining, prompting the provincial government to recommission it as a provider of an alternative and cleaner power.

Power Plant Technology

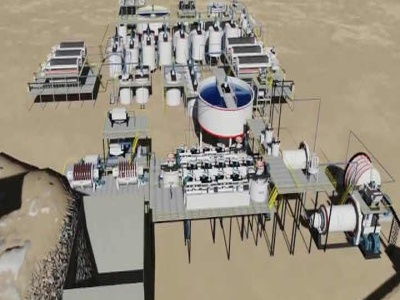

Steam and Water System in Coal Fired Power Plant System General Description Feed water is heated in the economizer then enters the steam dr... Read More . boiler, Coal, power plant, pulverizer. General System of Coal Pulverizer General System of Pulverizer It is a positive pressure direct air swept pulverizing system with 5 HP963 medium speed coal pulverizers p... Read More . Subscribe to ...

COALTECH

Additive for pulverised coal to produce more energy from less coal, while reducing emissions by up to 15% – without changing machinery in coalfiring power plants. Additive for nonpulverized coal to maintain its original gross calorific value (GCV), while stored for longterm purposes in .

Power Coal Fired Coal Pulverizer

Pulverizer For Coal. Coal fired power plant pulverizer gear coupling failure pr 20, 2015large electric motors use a worm gear arrangement to drive the coal pulverizers and a blower that sends the pulverized coal to the furnaceshe shafts of the motor must be mechanically connected to the worm gear and blowerhe worm gear is a relatively small, yet vital. Read More; How To Use A Coal Pulverizer ...

Home

We provide trusted service in fabriion, Manufacturing, Engineering and Assembly of Coal Pulverizing Mills used in Thermal Power Projects. Kappati is a market leader in the field of manufacture of Assemblies, OM replacement parts, Engineering, and servicing for Coal Pulverizers RP, RPS, HP Mills form 603 to 1203 size used in 60 MW to 800 MW Power Projects.

Coal Power Plant | Boiler Journal

· Coal power plant is a power plant that uses coal as fuel. The working principle of coal power plant is a coalyard of Coal will be transferred by using a belt conveyor to the coal bunker. Coal from the coal bunkers will be destroyed in the Pulverizer so it .

How To Maintain a Coal Pulverizer? (All You Need To Know)

The airswept ball mill, also often referred to as coal mill or coal pulverizer, has the advantages of high production capacity and high coal flexibility, so it is favored by power plants.

Latest Posts

- صناعة الخرسانة في المملكة العربية السعودية

- مبدأ العمل لكسارة الحجر الجيري في مصر

- jew crusher Egypt للبيع

- كسارة الصخور ibag

- التطورات سحق المحمول

- مصنعي كسارة التصدير

- كسارة مخروطية محمولة مع مولد

- محطة كسارة الحجر في هيماشال pardesh

- دعم كسارة الحجارة فى مصر

- صخرة محطم مطحنة المحمولة

- المورد كسارة الفك في المكسيك

- الكالسيت المستخدم لمعجون الأسنان

- شركات تعدين الفحم في لوس انجليس كاليفورنيا

- بدء مصنع لتصنيع الاسمنت

- سعر الكسارة الفكية الأولية في مصر

- Crushed Rocks Business In Nigeriari

- Coal Handling Plant Of Kstps

- Small Scale Mining Equipment Conveyor Belt Line For Gravel

- Mining Equipment Design Filetype Prices

- Ton Stone Crusher Machine China Stone Crusher Machine

- Artificial Sand Crusher Machines 2c Artificial Sand Production

- Mobile Crome Refining And Processing Plants

- Business Proposal For Quary Mining

- In Malaysia Gold Ore Crusher

- 2019 New Type Used Jaw Crusher

- Paration Titanium Oxides Iron Sand

- Sand Monitoring Equipment

- Ball Mining And Industrial Services

- Mobile Tracked Crushing Plant Lemtrack

- Manual Crank Hand Cane Juicer