Manufacturer Of Iron Ore Slime Beneficmeion Plant

Proposal for DryStable SelfFluxing Sulphide Tailings | E ...

In iron ore pellet practice, both balling discs and balling drums are employed to form green pellets. Current iron ore practice favors the use of balling discs over balling drums. In iron ore pellet practice, the end product is a closely sized ( mm or in. diameter) pellet, a .

Sustainable mining a must to meet demand

· The wash plants have a 950 tonnes per hour combined feed throughput and are upgrading a – per cent iron ore up to 63 per cent iron at 50 per cent product yield. Boost for SIMEC Mining ...

Iron ore tailings dry stacking in Pau Branco mine, Brazil ...

· Vallourec's beneficiation plant produces concentrated iron ore lumps and fines in Pau Branco mine [6]. Tailings are composed of both fines (>45 μm) and ultrafines (<45 μm). Ultrafines are generated from the desliming cycloning of the magnetic concentration process, and .

HINDUSTAN DORROLIVER LIMITED

We are at present executing two Iron ore beneficiation projects such as MTPA slime ore and Fines beneficiation project for NMDC, Donimalai and also MTPA BHJ grade (very low grade) iron ore for NMDC, Donimalai which are first times of such plants in India.

beneficiation of iron ore slimes using hydrocyclone,

Beneficiation of iron ore slimes using hydrocyclone The iron ore slimes (d80 ∼ 50 µm) generated at Noamundi iron ore washing plant (TISCO), assaying 57% Fe, 4% SiO2 and 83% Al2O3, have been subjected to hydrocyclone studies The effects of different design and operating parameters have been studied to get a product suitable for subsequent use in the sinter mix The studies indie that it is ...

TechnoEconomic Feasibility Study

Soft iron ores, fines, and slimes can move up the value chain, as ... reliance on international suppliers of coking coal, and enabling the use of a broader range of domestic iron ore sources. Economic security; ... Matmor plant integrated with an Electric Arc Furnace.

Mineral Processing Equipment Manufacturer

Mineral Processing EPC. Our EPC provides mine owners with services including beneficiation test, mine design, etc..Our company is committed to solving the common problems of dressing plant such as budget overspending, schedule delaying, disputes of the manufacturers, unclear responsibility of aftersale service, etc.

Unishine Mining Machinery

Unishine Machinery company carries out design, production, assembly and testing according to the quality certifiion system standards. We have gained the Enterprise Credit Rating AAA Certifie, the main products have passed CE and ISO9001 certifie.

Beneficiation Of Iron Ore Slimes

Beneficiation Of Iorn Ore Slimes The beneficiation potential of the iron ore slimes produced from the washing plants and tailing ponds of kiriburu mines assaying up to 60 fe 334 sio 2 and 293 al 2 o 3 is analyzed to start with the ore slime was characterized in sufficient detail to revea,Beneficiation Of Iron Ore Slimes In India.

Indian Iron Ore Scenario : Low Grade Iron Ore Beneficiation

In addition to this, depletion of high grade iron ore, stringent environmental regulations involved in opening of new mines, problems involved in handling, disposal of tailings (slimes), and utilizing of iron ore at 45% Fe as a cutoff fixed by Indian Bureau of Mines, it is the need of hour to effectively beneficiate low grade iron ore.

Steelmaking

Steelmaking is the process of producing steel from iron ore and/or steelmaking, impurities such as nitrogen, silicon, phosphorus, sulfur and excess carbon (the most important impurity) are removed from the sourced iron, and alloying elements such as manganese, nickel, chromium, carbon and vanadium are added to produce different grades of steel.

![index []](/grz2kxi/1178.jpg)

![index []](/grz2kxi/691.jpg)

index []

area of Iron Ore, the company started to blend Iron Ore Slimes in Iron Ore Fines, for the first time. During the year, the blending was to an extent of %. During the year, the production of Value Added Steels increased to % from % in the previous year. Production of Cast rounds in 430mm size was commenced

Beneficiation Practices in the Sukinda Valley Area ...

supplier/manufacturer of machinery engaged in sale of their equipment or by consultants engaged in erection of plants, etc. This resulted in lack of development of proper flowsheet for optimum recovery of the valuables. ORE DEPOSIT CHARACTERIZATION Geologically, the chrome ore occurrences in Sukinda valley is mostly high grade, soft friable in

Office of the Comptroller and Auditor General of India

plants and development of coal and iron ore mines. The Report examines the production, evacuation and sale of iron ore, diversifiion activities and investment in joint ventures by NMDC Limited during the period from 201213 to 201617. NMDC Limited is the largest iron ore producer in India. It started its operations in the

beneficiation of iron ore slimes

iron ore slime beneficiation. Beneficiation Of Iron Ore Slimes In India DYNAMIC Mining The beneficiation potential of the iron ore slimes produced from the washing plants and tailing ponds of kiriburu mines assaying up to 60 fe 334 sio 2 and 293 al 2 o 3 is analyzed to start with the ore slime was characterized in sufficient detail to revea,Beneficiation Of Iron Ore Slimes In India...

All products of East Sea Corporation

Special Adhesive Binder for Making Iron Ore Slime Briquette . Place of origin: Korea; Appliion: Iron Ore Slime 1. Recycling iron ore slime 2. Effective waste management 3. CostSaving by recycling byproduct 1. Powder type binder for Iron ore slimes 2. Reasonable price compared to other binders 3.

CDE Meta sets the scene for sustainable minerals ...

CDE designed, manufactured and installed two plants with a joint capacity of 950tonneperhour of iron ore waste beneficiation for SIMEC at the Iron Baron and Iron Knob sites in the Middleback ...

Iron Ore Dry Beneficiation

To Sinter Plant Sinter Feed Tailings Sinter Feed Tailings 173/64 130/43 To Pond Legend Dedusting line 304/55 Feed Rate (tph)/Fe Dry slime Pond Producer Gas Plant for ore fines drying Pilot scale Waterless Iron Ore beneficiation studies need to be scaled up to the .

The Characteristics of Iron Ore Slimes and Their Influence ...

The flotation has been successfully applied to process the iron ore for the particle size (Ps) from 10 µm up to 150 µm. The presence of the slimes (Ps < 10 µm) is harmful on the reverse flotation of quartz, so they are usually prior removed by hydrocyclones. The main effects of the presence of slimes on the flotation are related to the increase on reagents consumption, the froth stability ...

Mine Tailings, Tailings in Mining, Gold Tailings ...

The iron tailings discharge from iron ore plant is in large amount, fine size and different types, and complex property, so Xinhai use the process of magnetic separation, flotation, acid leaching and flocculation to recover iron. Xinhai usually use allslime cyanide process and carboninpulp process to recover the gold from gold tailings.

PEAT (Pyro/ Energy/ Agri for Tshwane) An Agri Steel ...

to smelt iron ore and slime at the Arcellor Mittal plant in Pretoria West and to capture carbon in the ore in an enrichment proprietary process that produces Pig Iron which is much sought after with offtake agreements in place to supply local and international customers.

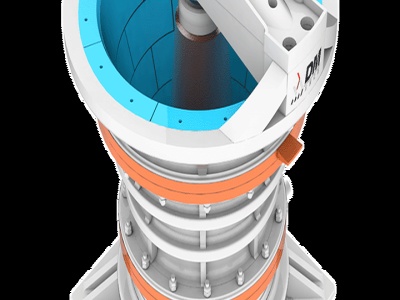

Hydrocyclone | Multotec

Engineered for maximum plant performance. The Multotec hydrocyclone range comprises cyclone diameters from 25 to 1 400 mm. Most of these diameters can accommodate a range of cone angles, while different vortex finders and spigot diameters are standard for all diameters. The small diameter cyclones, up to 165 mm, are predominately polyurethane ...

(PDF) MINING MINERAL PROCESSING Utilization of Iron ...

This paper describes an attempt to utilize iron ore slime in basic oxygen steelmaking as a coolant (instead of lump iron ore). Prior to its use, it is briquetted for ease of charging.

Latest Posts

- قائمة وحدات تكسير الحجارة

- كسارة تعدين الذهب المحمولة للبيع

- عملية تنطوي على معالجة الحجر الجيري

- نوع الآلة المستخدمة لسحق الخرسانة الصخرية

- Merchine كسارة الحجر في الأردن

- تستخدم كسارة تأثير عمودي رمح

- مطحنة كسارة كروية في العراق

- تقدير التكلفة لطحن السحق الكلي

- قائمة وحدات الكسارة في ولاية كيرالا

- صخرة الكسارة المصنعين مصر

- تقرير المشروع ل 200 tph محطم مخروط

- مصنع الاسمنت ألبانيا

- مطحنة الكرة في العراق

- مصانع درفلة الصلب للبيع في الجزائر

- المعدات المستخدمة في عجلت الكالسيوم مصنع كربونات

- Pabrik Beton Portabel Untuk Dijual

- Used Limestone Cone Crusher For Hire Comoros

- Manual For Symmons 5 1 2 Ft Cone Crusher

- Svedala China Cone Crusher Spare Parts

- Crushing Manufacturers In Usa

- Jaw Crusher Ebay

- Pressure Grinding Project Mill

- Slideway Mesin Penggiling Di Cameroon

- Ball Mill Poland In Greece

- Mobile Stone Crusher For Sale In Germany

- Icrusher Org Concasseur

- Grinding Vacuum Cup Wheel

- Prime Grinding Mill Bentonite Clay

- Mobile Line Crusher Operation

- Small Scale Gravel Crusher For Sale