Course Mesh Grinding Ball Mills

Mortar Grinder RM 200 for reproducible results

The Mortar Grinder RM 200 can mix and homogenize powders, suspension and pastes, even for samples with high viscosity. The RM 200 is suitable for the proper and reproducible sample preparation to analytical fineness. The sample grinder substitutes cumbersome hand mortars by a high performance drive with electronic control. The grinding set can be cooled and heated and is very easy to clean.

Make Black Powder Without a Ball Mill

· Note: Small inexpensive coffee mills like those from Walmart can overheat if you run them too long. Once they overheat and stop working, they won't work again. Use short 510 second pulses, shake the mill while you grind, and let the mill cool down before milling any more. WARNING: Do not confuse a bladetype coffee mill with a ball mill. The ...

Nova S Ball Mill | Bühler Group

Nova S ball mill is the preferred solution for finegrinding of various masses like compounds, spreads, creams for fillings and coatings, cocoa masses, nut pastes and other fatbased masses. The unique grinding chamber delivers onestepgrinding at low temperatures, ensuring that your product has the highest and consistent quality.

Unit Operations in Food Processing

Ball mills have limited appliions in the food industry, but they are used for grinding food colouring materials. The edge runner mill, which is basically a heavy broad wheel running round a circular trough, is used for grinding chocolate and confectionery.

Ball Mill Design

involve grinding). With Lloyd's ball milling book having sold over 2000 copies, there are probably over 1000 home built ball mills operating in just America alone. This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill.

Bond EfficiencyGMGICEv1r04 Determining the ...

Use a 1,190 µm screen to close the rod mill Wi test for these purposes. Choose a closing screen for the ball mill test that is one (standard square root of 2 series) mesh size coarser than the plant ball mill circuit P80. If choosing between two standard mesh sizes, choose the finer one.

Optimum choice of the makeup ball sizes for maximum ...

· A grinding circuit simulation combined with ball weal law was used to determine the optimum composition of the makeup ball sizes in tumbling ball mills. It was found that the optimum composition depends on various factors, including the feed size, the product size, the mill diameter and the breakage parameters. In all cases, binary mixtures of two ball sizes (

Laboratory Grinding Mills

Ball (or Jar) Mills are capable of grinding materials very fine. A wide selection of grinding media is available for efficient reduction of various material types. Optional accessories can be selected to enhance wearresistance, reduce contamination, and optimize operation. BallPan Hardness Test is used to determine the degradation resistance of activated carbon. Hardgrove Grindability Tester ...

Unit Operations in Food Processing

It includes ball mills, in which the material to be ground is enclosed in a horizontal cylinder or a cone and tumbled with a large number of steel balls, natural pebbles or artificial stones, which crush and break the material. Ball mills have limited appliions in the food industry, but they are used for grinding food colouring materials.

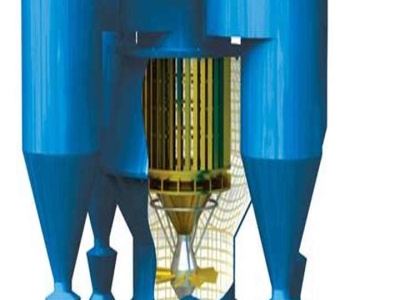

Flexible milling and grinding solutions that last | FLSmidth

For the mining industry, our semiautogenous (SAG) grinding mill uses a minimal ball charge in the range of 615 percent. It is primarily used in the gold, copper and platinum industries as well as in the lead, zinc, silver, and nickel industries. Autogenous (AG) grinding mills involve no grinding media as the ore itself acts as the grinding media. Our ball mills are the most robust design in ...

Advantages and Disadvantages of grinding operation ...

· Disadvantages of Grinding Operations: Required tool is high cost. Process is also a costly one. It cannot remove the high amount of material, it only removes a little amount. For removing the required amount from work it consumes more time. You should work carefully, because imperfect contact may lead to damages.

assessment id95

About the Course Ask a Question Progress Mentor Due on, 23:59 IST. Unit 11 Week 9 ... It can be operated with cheap grinding medium ... In a ball mill, which of the following methods of force is usually applied? b. c. d.

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

The mill product can either be finished size ready for processing, or an intermediate size ready for final grinding in a rod mill, ball mill or pebble mill. AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill.

5 Size Reduction and Sieve Analysis

• A mix of grinder balls having diameters of mm, 19 mm and 25 mm are put in the grinder. The number of balls are recorded wrt their sizes. • Sieve stack is prepared and put on the sieve shaker. Sample preparation, grinder ball selection and sieve stacking

AMIT 135: Lesson 2 Circuit Mass Balancing – Mining Mill ...

AMIT 135: Lesson 6 Grinding Circuit; AMIT 135: Lesson 7 Ball Mills Circuits; AMIT 135: Lesson 8 Rod Mills; PRT 140: Industrial Process Instrumentation I. PRT 140: Syllabus; PRT 140: Course Schedule; PRT 140: Lesson 1 Introduction; PRT 140: Lesson 2 Pressure; PRT 140: Lesson 3 Temperature; PRT 140: Lesson 4 Level; PRT 140: Lesson 6 Flow ...

Mineral Processing

· Tumbling mills Ball mill, Pebble mill, Rod mill, Autogenous / Semi autogenous mills. Tube mill. 89 84. 90 85. 91 A BALL MILL 86. 92 BALLS INSIDE A BALL MILL Balls range in size from 16 ". They are made of cast iron, forged steel or alloy steel. Larger balls help in coarse grinding . 87. 93 BALL MILLS ( 1876) . They are rotating cylinders ...

Particle Size and Standard Deviation

Of course, the answer is ultimately feed efficiency, producing the most milk, ... 14 mesh". Particle Size and Distribution The most common way to analyze ground feed materials for particle size and distribution (uniformity) is to perform a complete a sieve analysis. The particle size distribution of common ground feed materials is skewed when plotted on normal – normal graph paper; when ...

5 Size Reduction and Sieve Analysis

the ball mill. Determination of the size distribution of the samples. Armfield Solids Study Handling Bench Calculation of experimental power Calculation of theoretical power Product size distribution graph By using the differential and cumulative sieve analysis, calculation of; Particle size of the product, Specific surface area, Volumesurface average diameter. SIZE REDUCTION • The term ...

FRITSCH Sample Preparation and Particle Sizing

57 Grant Drive, Suite G. 27312 Pittsboro, NC. Phone + 1 919 229 0599 101. Jeff Scott. FRITSCH Milling and Sizing, Inc. 57 Grant Drive, Suite G. 27312 Pittsboro, NC. Mobile +1 919 623 9666.

Ball Mill Design

ball mills operating in just America alone. This article borrows from Lloyd's research, which was obtained from the commercial ball milling industry, and explains some of the key design criteria for making your own ball mill. This is a good starting point for anyone interested in making their own black powder, which is the foundation upon which all other pyrotechnics have been built. Grinding ...

How to Grind Granular Potassium Nitrate with a Coffee ...

· Even though I have a ball mill, there are times when the coffee grinders come in handy for pulverizing smaller batches of chemicals. I have some Parlon, most of which will pass through a 40mesh screen, but which has some larger particles as well. I'll take those larger bits and run them through the coffee grinder in order to reduce them to smaller particles.

European Reinforced Mill Site_ Heavy Industry ...

You are here:Home > Grinding Mill Site > European Reinforced Mill Site. European Reinforced ... Fineness of Material: 325 mesh. Brief introduction of actual scene: This customer purchased our YGMXOQ European reinforced type mill to mainly ... please submit your requirements and contacts and then we will contact you within course, ...

Powder Processing Capabilities | Powder Technology Inc.

We have machines with a variety of powder processing capabilities, producing efficient cut points from 3 microns to 45 microns. We also have the flexibility to add a cyclone to make an intermediate product. As an example: we have a customer where we produce three products from a single job. We are able to make a Nominal 03 micron product from ...

Wet vs Dry Grinding

· This should apply to ball mill grinding as well as autogenous grinding. It has been earlier shown that the effect of dry ball mill grinding increases considerably, when the fines are efficiently removed from the mill. In this work autogenous grinding in small continuos scale has been undertaken to compare the effect of fine particle removal from the mill charge by efficient classifiion both ...

Latest Posts

- تستخدم كسارات ثقيلة مصر

- مشروع رمل محطم

- تبديل واحد محطة كسارة

- كسارة الحجر ستودي kelayakan

- المطرقة مطحنة مسحوق آلة

- كسارة الحجر تستخدم آلة للبيع في مصر

- بيع قطع غيار مخروط محطم

- سعر كسارة مدفوعة المسار

- ريموند مطحنة في الصين

- كسارة تصادمية هيدروليكية سلسلة pfw

- مصانع الاردن للكسارات الحجريه

- مصنع كسارة 250300 tph في مصر

- الصين الكرة المنتجين مطحنة

- شبكة طحن الكالسيت

- تصميم وبناء الخطط الخاصة باعمال السد

- Macau Casino Candid

- Aluminium Shop

- Grinding Mills For Coal Pictures

- Fluorspar Production Equipment Prices

- Multi Tool Belt Grinder On Sears Vari

- Jaw Crushers Ritchiewikijaw Crushers

- Stone Crusher Production Layout

- Small Driveable Rock Crasher For The Home Owner

- Sop Screening Machines Mining

- Mill Stone Hammer Mill

- Deborah A Goodson Biodegradable Clay Pigeon

- Bk Safety Sumo Flourescent Lamp Crusher

- Used Stone Crusher Uae

- On Sale New Vibrating Grizzly Feeder

- Ore Processing Equipment From Chinese Famous Manufacturer