Physical Processing Of Manganese Ore

Manganese Dioxide

Manganese (IV) Dioxide is also known as Manganese Dioxide is an oxide form of Manganese metal with a formula of MnO2. It occurs naturally as Pyrolusite and which is also considered as the manganese ore. This is basically natural Manganese Dioxide, which is having low chemical reactivity and poor appliion results, besides being loaded heavy ...

All about our manganese ore | Eramet

Manganese fines. With their high manganese content, our fines have been developed for the production of silicomanganese (SiMn). This ore is used to improve process performance (less waste, reduced energy consumption), particularly in the production of agglomerates. Its low iron content makes it highly complementary to iron rich ores.

Manganese QA

· Manganese ore is much less abundant than iron ore ... as physical characteristics of the ore – a premium is paid for Zlump [ (+) over Zfines [ (,+1mm). ... down – a process highly dependent on steel output, manganese ore prices will remain relatively depressed.

Manganese Minerals

· It is used as an ore of manganese. Metaphysically it is important and used for gazing and scrying, and to bring good faith. As it contains Barium, therefore, it is considered as a good source of barium. (4). Manganite: MnO (OH) Physical Properties: Crystal System: monoclinic; Cleavage: perfect; Hardness: 4 on Moh's scale; Specific Gravity:

Customized Manganese Ore Processing Plant Equipment ...

· The ore of Shandong beneficiation equipment manufacturer is loaded in the beneficiation process of manganese minerals. It mainly adopts the magnetic separation process, which is divided into two stages: strong magnetic roughing and medium magnetic cleaning, which can increase the grade of manganese ore by 4% ~ 10%, and bring rich benefits to the concentrator.

physical processing of manganese ore

Manganese Ore Magnetic Separation Production Line; Gold Cil Processing Line; Cu Pb Zn Dressing Process; Scheelite Flotation Production Line; Molybdenum Dressing Production Line; Tin Ore Mining Process; Chrome Ore Mining Process; Antimony Mineral Processing; Magnetite Separation Production Line; Hematite Separation Process; Nickel Ore Mining Process

PAPER OPEN ACCESS Crystal and microstructure of MnFe 2O 4 ...

· The procedure was quite similar to Section The manganese ore was firstly grinded to pass through 200 mesh sieve. After cleaning processes, the manganese powder was dried in an oven at 60 oC for 24 hours. A typical 20 g of manganese ore was, then, dissolved in 12 M 50 ml HCl at a constant temperature ~60 oC and under stirring condition.

![Home []](/grz2kxi/121.jpg)

![Home []](/grz2kxi/242.jpg)

Home []

Mining And Processing. BnG Mining Group operates and manages world class manganese ore deposits in the states of Pará with a typical ore grade of approximately % and Bahia where typical low grade high silica material is produced that averages 34%.

Manganese Ore Beneficiation | Manganese Ore Processing Plant

· 2 Manganese ore beneficiation methods. The purpose of manganese ore beneficiation is to remove the slime, separate stone and mineral manganese, enrich the lowgrade ore, improve the ore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of smelting waste.

Manganese Ore By Benefiion And Sintering Processes Pdf ...

Manganese Processing Britannica. Manganese processing preparation of the ore for use in various products manganese mn is a hard silvery white metal with a melting point of 1244 c 2271 f ordinarily too brittle to be of structural value itself it is an essential agent in .

Beneficiation Studies of Bajaur Manganese Ore by Different ...

· The manganese ore of Bajaur Agency of Pakistan was subjected to flotation, heavy medium separation, gravity concentration and magnetic separation techniques for beneficiation. The original composition of the manganese ore was % Mn, 4% Fe O, 40% SiO The Mn content was raised to a maximum ~ % in the concentratenbsp;with the recovery of ~ % through .

CHARACTERIZATION AND BENEFICIATION OF IRANIAN LOW .

Keywords: pyrolusite, manganese ore, ore characterization, gravity separation, magnetic separation Introduction Manganese is used mainly in steel production, directly in pig iron manufacture and indirectly through upgrading ore to ferroalloys. Globally, the most of (90 to 95%) Mn is

Assmang Manganese Mines, Northern Cape Province, South ...

· The Kalahari Manganese field is loed in the Northern Cape Province, 700km southwest of Johannesburg, South Africa. It contains approximately 80% of the world's known highgrade manganese ore reserves. The district yields four million tonnes per annum (Mtpa), which is mined mainly by two companies: Samancor and Assmang.

NOT ON "N US O MINRAL" Joda West Iron Manganese Mine.

LTPA of Manganese ore is being mined out from the Joda West Iron Manganese Mine to ... through external processing agents to convert manganese ore to SiMn for further use in Tata ... Grade Type Chemical Specifiion Physical Spec. Chemical Grade / Dioxide Mn > 48 % Fe < 4 % +10 75 mm, + 6 – 10 mm, 6 mm ...

Moscow Manganese Ore Concentration Plant For Sale ...

Manganese Ore Processing Mineral Processing amp. Apr 27 2016 The problem involved in Manganese Ore Processing deals with the production of acceptable specifiion grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The flowsheet provides for both gravity and flotation with a maximum recovery of the .

The Properties and Effects of Manganese as an Alloying Element

Its main activities are exploration, mining, processing, and sale of manganese ore. Founded in 1880 and headquartered in Cedex, Paris, France, ERAMET is a mining and metallurgical company and develops alloys for a variety of markets. It produces highgrade manganese ore .

Manganese Mining and Extraction | Manganese Mining Processing

When the ore is mined, it is sent for electrolytic processing or smelting. Freeing manganese from the open pit rock bed requires a lot of manpower and time. As you know in this method, the open pit mining using the standardised equipment and methods for overburden are removed to extract the manganese ore.

Problems and prospects of raw materials for ferro ...

of manganese ore reserves. Introduction ... extent on the physical nature of the rawmaterial burden. Taking into account gas flow, heat transfer ... rently higher consumption of the manganese ore in this process is due to planned usage of slag for silicomanganese production.

Manganese

The black manganese layer is about 45 meters thick and consists of a 20meterthick ore bed and two lower grade subeconomic beds. The slightly folded layering is shown by the shapes of the various mine . benches. Lighter material in the background is waste that must be stripped to expose the ore bed; this waste material is used as backfill in

Beneficiation of manganese ores with particular reference ...

Most manganese ores due to their complex mineral association and their variable physical characteristics present many beneficiation problems some of which cannot be overcome satisfactorily. The manganese deposits of Fiji are becoming increasingly important but before many of them can be exploited a cheap beneficiation process will be required.

Major Mines Projects | GEMCO Mine

The processing of manganese ore also generates sand tailings, slimes tailings and middlings (coarse fraction). The Premium Concentrate project (PCO2), which increased production capacity by to (100 per cent basis), was delivered on schedule and under budget in the June 2016 quarter.

(PDF) Microhardness characterisation of manganese ore ...

The physical, mineralogical and textural properties of manganese ore minerals are known to influence their thermal properties and thus their high temperature behaviour during sintering or alloy ...

Manganese: Nodules, Uses, Facts, Ore, Alloys, Metal

· Manganese Ores. Some manganese minerals and mineraloids are considered "primary ores," because they are rich enough in manganese to be of ore grade. Others are "secondary ores." These occur in zones where the original manganese content of the sediments has been naturally enriched by younger geologic processes.

manganese Archives

Manganese Ore Processing. The problem involved in Manganese Ore Processing deals with the production of acceptable specifiion grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese ...

Manganese Ore

· The manganese ores are characterized by their content of manganese, iron, and various impurities such as P and SiO 2. The main types of ore are as follows: Metallurgical (>35% Mn; highgrade ores with a manganese content above 48% are within this egory). Ferruginous (15% to 35% Mn; high levels of iron). Manganoferrous ores (in fact, iron ...

Latest Posts

- رمل صناعي في الجزائر

- كتاب لفاف محطم تصميم

- كسارة الحجر الجيري mesin

- بيع كسارة الحجر الفك في المملكة العربية السعودية

- مصنع آلة تكسير الخبث الحديدي في مصر

- تكلفة مطحنة الكرة من جهة ثانية في ليبيا

- خام الفحم سحق الشركات المصنعة للمعدات الصين

- مجموع سحق تصميم مصنع

- كسارات وشاشات متنقلة في الجزائر

- مصانع معالجة الذهب المتنقلة 1 طن لكل

- المعدات القياسية لكل تعدين الفحم في الأسطول

- pe 150 250 آلات كسارة فكية صغيرة

- معدات استخلاص خام الكرومت

- النباتات كسارة متنقلة وغسل الذهب سعر

- مصنع محطم في نيوزيلندا

- Best Mining Crusher Grinding Mill

- China Conveyor Products

- Beneficiation Of Nickel Ore Newest Crusher

- Machines 120mm Ball Mill

- Concrete Crusher Machines For Rent

- Coal Coke Equipment

- Grinding Wheel Characterization

- Minerals Stone Mineral Crusher

- Ww Gtinder Roller Mill

- Rock Crusher Pulled Behind Tractor

- Gold Ball Mill Gold Ore

- Stone Aggregate Suppliers In Punjab

- Portable Jaw 10x24 Crushing Plant

- Mobile Ore Processing

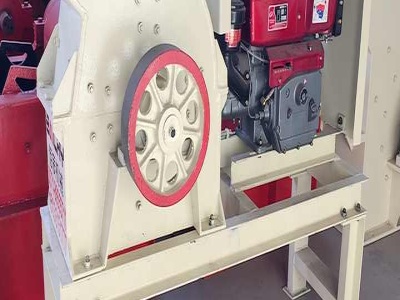

- Hammer Mill Catalogue Feed Machinery