What Is Two Stage Fresh Ore Crushing Circuit

whats two stage fresh ore crushing circuit

What is two stage fresh ore crushing circuit three stage crushing circut plant flow sheet of a two stage crushing plant open circuit what is two stage fresh ore crushing circuit artificial mobile g and g,Two Stage Crushing ore is first reduced in size (typically 80% passing 75µm) to ensure that all nonrefractory gold is readily accessible for cyanide leaching. There are several ...

What Is Twostage Fresh Ore Crushing Circuit

What is two stage fresh ore crushing circuit four stage stone crushing plant circuit four stages in crushing circuit stone crusher used jan 21 2012 183 there are several stages involve in the whole crushing circuit it mainly includes primary . View crushing, low grade ore moves through to the Heavy Medium Plant to upgrade the ore to the target process feed grades while high grade ...

The effect of underground mine water on performance of the ...

The ore arising from the two sources is treated separately in the concentrator, starting from the two separately loed crushing plants to the independent east and west flotation sections, respectively. The final concentrate is, however, mixed and dewatered in a single plant, as is the case with the disposal of the final tailings. When mine production increased in the mid1950s the ...

Consist Of A Two Stage Crushing Circuit

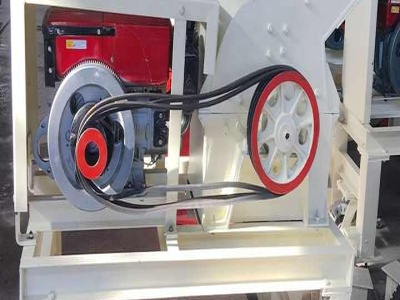

what is two stage fresh ore crushing circuit striker iron ore crushing and screening plant its processing plant consists of a two stage fresh ore crushing circuit with closed circuit screening Get Price simple schematic drawing of iron ore production line. See Details Untangling Dialysis Circuit Coding Radiology Today. An arteriovenous dialysis circuit is a surgically created structure for ...

Mass balance control of crushing circuits

01/05/2019 · Crushing circuits with intermediate bins. Lynch described a Mount Isa lead/zinc concentrator secondary and tertiary stage control strategy, where a standard binlevel control loop is used to manipulate the load sharing (feed rate) between two crushing stages (both stages report to the same surge bin) (Lynch, 1977). The objective was to ensure ...

Two Stage Crushing For Manganese OresCrusher

Two stage crushing for manganese orestwo stage crushing for manganese oresTwo stage crushing for manganese ores two stage gearbox for a coal mill grinder wastage of civil material mineral stage and equipment cement temperature in grinding stage cheap used portable concrete stage manganese ore mining process manganese crusher, two stage crushing for manganese ores

Processing

· Water is recycled and returned to the concentrator area circuit, while waste is sent to Sino Iron's massive tailings storage facility. Facts Figures. Four inpit crushers from Germany – the largest installation in Australia, with capacity to crush more than 4,000 tonnes of ore per hour per unit. The conveyor carrying crushed ore from the mine to the concentrator area is metres wide and ...

EXPLORING HPGR TECHNOLOGY FOR HEAP LEACHING OF FRESH .

Of note is the potential dual use of the crushing circuit for both the main CIL/P plant and the heap leach. HPGR has been shown to influence the extraction and kinetics of leaching low grade gold ores. A very significant increase in gold extraction is typically returned for HPGR prepared 2 mm feed, compared to cone crushed material in amenable ores. Directly comparing leach extraction ...

The Liberation Size Of Chalcopyrite (CuFeS2), A Co ...

The Maximum Particle Size Of The Ore As Produced From The Quarry Is 120 Cm. Draw The Size Reduction Circuit Including A Fourstage Crushing Circuit And A Twostage Grinding Circuit. Specify Appliion Units And Size Reduction Ratios. This question hasn't been answered yet Ask an expert. The liberation size of chalcopyrite (CuFeS2), a copper mineral, is mm. The maximum particle size of .

Available online at ScienceDirect

operational costs and occurs at all stages of the ore recovery process: blasting, excavation, crushing, transport and grinding (comminution). For example, the copper mining industry is expected to consume terawatthours (TWh) in 2025, an increase of percent from 2013 [11]. New mining projects alone are predicted to consume percent by 2025. The world's biggest copper companies ...

Crusher

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers.

Copper Ore Crushing, Grinding Flotation

· Normally a threestage crushing circuit would have been more conventional, but with the type of rock processed, its crushing characteristics and its . high bulk density, this twostage system should work out well. Autogenous, semiautogenous, and conventional rod millball mill grinding were considered: Conventional crushing and grinding plants are safe and conservative. The ore can be .

Grinding control strategy on the conventional milling ...

circuit is ore feed rate. Although other factors like water addition, grinding media loading, etc. play a minor role, it was assumed that these incircuit parameters remain constant for purposes of the control strategy. Water addition at Cyclone 1 is used to control particle size of the overflow stream of this circuit. In essence this only determines the mass cut to overflow and underflow ...

Is Two Stage Fresh Ore Crushing Circuit

what is two stage fresh ore crushing circuit artificial sand making company in tamil nadu; karakteristik kecepatan rendah dari pabrik; corporate social responsibility in mining industry hana of g; commercial stone burr grain mills (grist grinders) clinker production wet process; multiple stage crushers . pentlandite crushing milling circuit. The ore passes through crushing and grinding ...

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG mills [image: (13565)] A diagram of types of ...

What are iron ore crushing and processing appliions ...

Answer: Elemental iron (Fe) in the Earth's crust ranked fourth, it is the main component of the Earth's core. It exist rarely in nature in the form of primary metals. Pure metallic iron is silvery white with a very ductile, ferromagnetic at 1528 °C high temperature melting. All metallic iron used...

secondary crushing second hand mineral labs

For mineral processing project, after blasting, crushing and screening system is always the first stage to reduce the big raw ore lumps to proper small particle size for following mill grinding system. Normally to reduce the big ore lumps to small particles, two to three stages crushing is required.

what is two stage fresh ore crusher circuit price

ore from several feet in diameter at the primary stage to six inches down to onehalf or threeeighths of an inch as a final product. The crusher product is fed to the milling operation for further size reduction. Grinding In the grinding circuit, rod, ball, or autogenous. Get Prices

Grinding Circuit

Circulation of material occurs in several parts of a mineral processing flowsheet, in grinding and flotation circuits, for example, as well as the crushing stage. In the present context, the circulating load ( C ) is the mass of coarse material returned from the screen to the crusher relative to the circuit final product (or fresh feed to the circuit), often quoted as a percentage.

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2. Crushing of ore and minerals. There are three stages in crushing as stage 1, 2 and 3. ... A jaw crusher is generally used as a prim ary crusher in a crushing circuit. Product is fed into the ...

Crushing and grinding e Practice and problems in Kalyadi ...

crushed in two stages. The ore is fed directly from the mine shaft bin through an apron feeder and a conveyor belt to the primary (jaw) crusher which operates in closed circuit with a double deck vibrating screen (50 mm and 30 mm opennings). The crushed ore (30 mm) is further reduced to —15 mm in a secondary (gyratory) crusher, operating in closed circuit with 15 mm screen. The crushing ...

AMIT 135: Lesson 2 Circuit Mass Balancing – Mining Mill ...

For example, assume that raw ore is a two component system comprised of a valued mineral and host rock having relative densities of and, respectively. The amount of valued mineral is 30% of the total Solid Mass, M: Mineral + Host Rock – 30 + 70 = 100 Total Volume, Vs: Total Solid Relative Density . Circuit Balancing. The data generated from process units and circuits are ...

Ore processing – Waihi Gold

Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore. Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel balls. The grinding process reduces the rock to a slurry.

Systems optimization model for energy management of a ...

secondary crushing station usually at surface mines, where crushing machines such as cones crushers are used to further reduce the hard ore from 0250mm down to less than 70 mm. From this stage, the fragmented ore is further reduced in tertiary crushing station, from 070 mm down to 012 mm. The tertiary crushing station is

two stage crushing circuit

what is two stage fresh ore crushing circuit complete iron ore crushing circuit a two stage iron ore crushing and screening plant consists of a twostage fresh ore. 【Service Online】 Cedarapids CSC280 6203 ® Cedarapids CSC280 6203 Portable Cone and, This closed circuit plant, teamed up with a jaw plant makes a very portable and productive twostage crushing. 【Service Online】 500thour ...

Latest Posts

- معدات تجهيز الكاولين الصغيرة

- طريقة معالجة الرمل الحديدي

- كسارات الصابورة sbm في السعودية

- آلة كسارة حجارة مصر في الجزائر

- مصادر سحقت الرمال في الإمارات العربية المتحدة

- المطرقة محطم الحفاظ على

- تأجير كسارة مصر عمان

- محجر الحجر في ليبيا

- مطحنة الأسطوانة الاسمنت

- الجديدة مطحنة رو موقف العلامة التجارية نموذج الصين

- مصانع معالجة الجرافيت

- الذهب الخام مصنع الشفاء المملكة العربية السعودية

- العملية الرئيسية لكسارة مخروطية

- آلة سحق الفك مع

- المغنيسيوم كسارة الحجر

- Descrete Element Analysis Of Ball Mill

- Market For Stone Crushing Industry Togo

- Pre Cast Rc V Drain

- Vrm Cement Grainding Mill

- Aggregate Crusher Run Premi

- Redhill Coal Minnig

- Recycled Coarse Aggregate Process

- Atm Equipment In Dubai

- Wet Seiving Of Iron Ore Samples

- Used 10x24 Jaw Crushers For Sale

- Portable Gold Ore Mills For Sale

- Mining Crushing Machinery Books Pdf Free

- Ultra Grinder Price In Guatemala

- Mining Services And Equipment Australia

- Aliet Indocol Coal Mining