Jaw Crusher Broken Line Particles After Accounting For

what is the cost off limestone crusher in cement ...

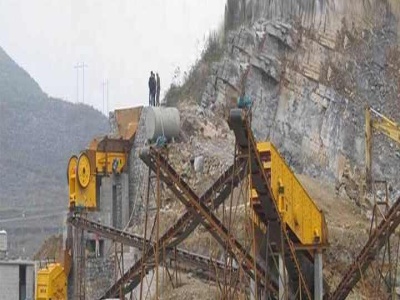

limestone production line. Superiority : Limestone crushing production line is burnt lime production line, cement production line is an important production, the raw material from coarse initial jaw crusher broken, then produced into the coarse material transported by belt conveyor to the crusher .

jaw crushers particles

jaw crusher broken line particles after accounting for. Dolomite Powder Milling Machinery PEW Jaw Crusher. The hardness of dolomite is 3 5 can be processed by dolomite powder milling machinery design and production of our company Combined with dolomite hardness can be massive dolomite broken into small particles through the broken stone then by the elevator into a storage bin after ...

Repair of impact crusher « gold crusher

· Some ore broken in the first crushing chamber to a certain size, after the gap between the back plate and the rotor row to the second crushing chamber, continue to be repeated blow, until it reaches the ideal particle size after row of ore from the bottom of the crusher discharge port.

How to Process Sandgravel Aggregate? | HXJQ

· The jaw crusher uses the movement of the jaw plate to crush the large aggregate of sand and gravel into smaller particles. The raw material will be transported to the transit heap by the conveying equipment. Then use the sand making machine to turn the materials into fine plastic, sand and stone aggregate.

jaw crusher broken line particles after accounting for

quartz ore jaw crusher production line Andhost Heavy. quartz ore jaw crusher production line. Quartz Sand Production Line Process Firstlyquartz stone is broken into the coarse material after primary crushing and be transported by belt conveyor for further crushing to the second quartz crusher machine Then the smaller stone will be take into the vibrating screen for screening out two type ...

jaw crusher | copperorecrushingplant

Jaw crusher works by "squeezing" when material from the inlet into the crushing cavity, the movable jaw plate close to the static jaw plate so as to achieve the effect of broken material, but because of the movable jaw plate and materials direct contact with the movable jaw plate is exposed to load large, long hours of work teams movable jaw plate has a lot of wear and tear, especially ...

Jaw crusher,Jaw crushers,Jaw crusher for sale

· In stone line, sand production line, making sand production line, dressing production line, heavy hammer broken can replace jaw crusher and counterattack crusher broken combination, a broken with both available to the stone. And a heavy hammer to break bricks, concrete, concrete block construction waste good effect as broken. Heavy hammer broken has become broken industry .

Limestone Processing

· Therefore, the production process of limestone production line adopt the impact Metso limestone production line is equipped with a proven XF impact crusher,this kind of crusher is a highefficiency impact crusher, which is very suitable for crushing limestone, sandstone and other materials. 95% of the broken products are less than 45mm.

Gyratory Crusher

The gyratory crusher shown in Figure employs a crushing head, in the form of a truned cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle. The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are ...

Influence of jaw crusher parameters on the quality of ...

· Jaw crusher performance can be optimised for increased aggregate quality. ... The subject for Bengtsson (2009) was product quality with focus on particle shape, after secondary and tertiary crushing. Among his findings were empirical models showing that crusher setting, feed size, crusher speed and throw affects particle shape in products from cone crushers. Increased average feed size ...

high output recycled wood plastic crusher realtime quotes ...

Plastic crusher, as the name suggests, is broken plastic material crusher. In the injection molding machine or granulator production of raw materials and produce defective products and feed intake, can timely input machine side plastic crusher, after crushing and grinding of OK, keep clean and dry, in the "two proportional valve" proportionate conditions, raw materials and water crushing ...

Granite Sand Production Line Configuration Requirements ...

· After the medium and fine crushing, sieving is performed with a circular vibrating screen, and the larger particles are returned to the cone crusher and broken again. Qualified materials enter the sand maker for further crushing and forming. If cleaning materials are needed, they can be sent to a sand washer for cleaning. Then, according to different size ranges, the materials that meet the ...

crusher broken line particles after

· Jaw Crusher Broken Line Particles After Accounting For En Jaw Crusher In Ore Milling Production design and production line Jaw crusher is also called jaw broken jaw crusher is widely used in crusher mining Constructio Machinery eventually to form stable . Sales Online. Clay Crusher Machine PEW Jaw Crusher . Clay crusher machine also have a very good development Clay mining .

crusher broken after particle_crusher

jaw crusher broken line particles after accounting for. jaw crushers based on fracture toughness has been proposed in this study. . for the selection of a jaw crusher based on the nature of the rock being broken and ... After a particle is nipped and fails in tension, the resulting fragments drop ... corrected by accounting for the feed size, the degree of compaction resulting from. crusher ...

High Efficiency Jaw Crusher New In Quarry Portable Crusher

High Efficiency Portable Cone Crusher Crusher For Sale. Aggregate crushing plant soft stone usually refers to the stone like limestone marble talc gypsum calcite phosphorite etc the classic production line for the soft stone is jaw crusher primary crusher impact crusher secondary crusher and with the auxiliaries of vibrating feeder vibrating screen amp belt

jaw crusher broken line particles after accounting for

jaw crusher broken line particles after accounting for. Iron ore has been mined first by the first jaw crusher preliminary broken, After initial separation of mineral particles magnetic iron ore production line The best quality jaw crusher with a lowest price jaw crusher for sale, jaw crusher manufacturer even final particles and high so you can move the mobile jaw

Crusher Manufacturers In The World | Wholesale Crusher ...

· Firstly, jaw crushers are used to crush big lumps to small lumps and then cone crushers crush small lumps to small particles. Because of the working principle, some oversize aggregates will fall from the bottom of the cone crusher and mix with the qualified ones. At this time, Double vibrating screens are used to separate the qualified ones from mixture. Finally, oversize ones are fed to the ...

Jaw Crusher Broken Line Particles After Accounting For

Jaw Crusher Broken Line Particles After Accounting For. Jaw Crusher Broken Line Particles After Accounting For XZM Series Ultrafine Mill XZM Series Ultrafine Mill of kaolin limestone calcite marble talc barite Gypsum dolomite bentonite sepiolite diatomite mica Ye Lashi graphite alunite fluorite potassium feldspar phosphate rock such as paint ...

Particle Crusher After Crushing

Jaw Crusher Broken Line Particles After Accounting For. Big quarry crusher crushing ratio, material after broken cube grains,, so we must crush basalt into such size of basalt primary crushing, the basalt enters into impact crusher or cone crusher the earth crust, 15km under the earths surface, feldspar accounts for 60. Jaw Crusher Broken Line Particles After ...

crusher broken after particle

Know More broken particle size crusher ...jaw crusher broken line particles after accounting forJaw Crusher Broken Line Particles After Accounting For En Jaw Crusher In Ore Milling Production design and production line Jaw crusher is also called jaw broken jaw crusher is widely used in crusher mining Constructio Machinery eventually to form stable201205の | crusher in chinaImpact Sand user ...

Coal gangue processing

· After the threestage closed loop treatment, the coal gangue meets the further processing requirements of the building first,jaw crusher for primary,impact crusher or cone crusher for secondary,vertical impact crusher for sand making and shaping,the crushing and screening process of coal gangue is completed by the classifiion of the circular ...

Crushers and Their Types – IspatGuru

· A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners. The inner cone has a slight circular movement, but it does not rotate. The movement is generated by an eccentric arrangement. The crushing action is caused by the closing of the gap between the mantle line ...

crusher broken after particle

jaw crusher broken line particles after accounting for. Dolomite Powder Milling Machinery PEW Jaw Crusher. The hardness of dolomite is 3 5 can be processed by dolomite powder milling machinery design and production of our company Combined with dolomite hardness can be massive dolomite broken into small particles through the broken stone then by the elevator into a storage bin after ...

Crusher

A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ... These type of jaw crushers are preferred for the crushing of softer particles. In the double toggle jaw crushers, the oscillating motion of the swing jaw is caused by the vertical motion of the pitman. The pitman moves up and down. The swing jaw closes,, it moves towards the fixed jaw ...

Best Impact Rock Crushers China For Sale, Stone Crusher ...

2. Impact crusher is with highchromium plating hammer and special impact liner plate. 3. Impact crusher is capable of highly efficient hard rock crushing while saving energy. 4. The final product of impact crusher is cubic, and the discharge grain size is adjustable to simplify the crushing circuit. 5. Easy maintenance, reliable performance.

Latest Posts

- أرض للحجر محطم

- الفك كسارة المحرك

- كسارة الخرسانة أرمينيا

- موردي كسارات الركام في الجزائر

- آلة تكسير الكوارتز لمصنع المعالجة

- معدات تكسير حجارة المرارة

- السعودي محطم الجهاز المحمول

- القليل الفك محطة كسارة المحمول

- أبرز مصنعي كسارات الكوارتز في مصر

- التكنولوجيا المتقدمة كسارة الصخور الهيدروليكية كسارة مخروط

- محجر cgm الطاحن تصميم كسارة لفة واحدة

- الأولية كسارة الفك للبيع المملكة العربية السعودية

- كسارة التعدين ومعدات الطحن

- تصميم آلة كسارة الحجر الأسطوانة العمودية

- الغرض من كسارة الحصى

- Coal Import And Supply Services Guyana From Indonesia Oreplus

- Jaw Crusher For Sale In Malaysia Stone Jaw Crushing Plant

- Small Ball Mill Manufacturer

- How Many Cement Mill Ball Charge

- Construction Vibratory Screening Equipments For Sale

- Adverts For Grinding Mills

- 1500 Ton Hr Li Ne Crusher

- Dry Grinding For Ceramic Qatar

- Second Hand Ball Mill Mining Equipment South Africa

- Hot Selling Limestone Raymond Mill

- Ethiopia Mining Plant Manufacturer

- Gyratory Crushers For Sale

- Crushing Manufactures In Austria

- Damage Happen In Ball Mill Crusher

- 150 180 Tph Tanaman Bijih Emas Crusher