Ball Mills Initially

Ball Mill: Operating principles, components, Uses ...

· A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size. The large balls tend to break down the coarse ...

Grinding Machines Initially

Apr 04, A grinding wheel, initially at rest, is ro tated with constant angular acceleration of rads2 for s. The wheel is then brought to rest with uniform deceleration in rev. Find the angular acceleration required to bring the wheel to rest. Note that an in crease in angular velocity is consistent with a positive angular acceleration. More Details. Historical ...

Taurus

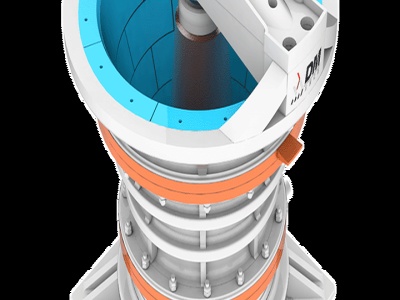

Taurus Ball Mill for Fine and Ultrafine Products. NETZSCH Ecutec's Taurus has the most advanced technology in Mills using Grinding Media for micronizing. A rotating robust steel drum with liners is supplying kinetic energy to grinding media inside the mill. These grinding media are crushing and grinding fresh product due to impact and friction. The lining as well as the grinding media can be ...

OSG | Taps | End Mills | Drills | Indexable | Composite ...

Ball End Mills Ball nose end mills, featuring a full radius, are ideally suited for milling 3D contoured parts. The full radius, or ball shape, permits high accuracy contouring and profiling while minimizing corner chipping more prevalent with square and corner radius end mills. View Ball End Mill Offering . Ball Nose Solutions. List 9510. EXOPRO ® PHX. 3Flute, Ball End, Metric View Product ...

End Mill Series

End Mill Series. 1 2mm y 0 20 40 60 80 100 120 VF2SB VF2SB VF2XLB VF2SB R3 DH31S (52HRC) 16,000min1 (284m/min) VF2XLB NAK80 (43HRC) 20,000min1 (68m/min) a a a a a a 3700HV 100N 1300°C 3200HV 80N 1100°C (Al,Ti,Si)N 2800HV 80N 840°C (Al,Ti)N Features Miracle end mills for increased cutting speeds, efficiency and tool life .

ERSEL Ağır Makine San. ve Tic. A.Ş.

* SAG mills are the machines with the highest reduction rate which performs crushing, grinding and washing together. It offers a much higher reduction ratio than 3stage crushing and screening system. * Feeding material in the dimension of 200300 mm, is reduced to d100: 2 mm and below. This capability increases the efficiency of the ball mill while reducing the circulating load of the system ...

How to Make a Ball Mill: 12 Steps (with Pictures)

· Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill. Using a motor, container, belt, caster wheels, and some basic building ...

Copper Mountain Mining announces commissioning of the Ball ...

· The installation of the third ball mill completes the Ball Mill 3 Expansion Project which will increase plant milling capacity to 45 000 tpd from 40 000 tpd. "We are pleased to announce the start of commissioning of the new ball mill on schedule," stated Gil Clausen, Copper Mountain's President and CEO. "With electrical commissioning kicked off, we plan to introduce slurry to the mill ...

Home :: TECHNOLOGY

The modificantions include ball mills and vertical mills as well as preheater, klin and cooler upgrades and complete plant. NO JOB IS TOO SMALL AND NO JOB IS TOO BIG. Technology Public Company Limited performs a wide rande of cement plant modifiions and more than 867 orders have been placed for conversions. The modificantions include ball mills and vertical mills as well as .

ball mills initially

ball mills initially. Apr 24, 2020 Ball mill and Rod mill is a tool used in modern mineral processing, coal chemical industry, sand making and other industries to grind ore into powder and then used in smelting industry to smelt gold, steel, etc. Coal chemical industry coal water slurry is gasified to make chemical raw materials, and sand making is used for glass or building sand.

Ammonia synthesis by mechanoalysis in a ball mill

· Unimagined effect: The grinding process in a ball mill activates a alyst in such a way that it facilitates the synthesis of ammonia at a much lower temperature and pressure than is necessary in ...

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the ...

Ball Mills Initially

· Ball Mills Initially. Ball mills tumble iron or steel balls with the ore the balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds the feed to ball mills dry basis is typically 75 vol ore and 25 steel the ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones chat.

What is a ball mill? What are its uses and advantages?

Answer (1 of 12): Extraction of Gold by Cyanide Leaching The cyanide gold extraction process is one of the most widely used gold ore beneficiation processes in gold recovery, which can be divided into many types. And there are different cyanide gold extraction processes in gold recovery equipmen...

Ore Dressing Ball Mills Initially

Ore Dressing Ball Mills Initially. Ore Dressing Realtime monitoring of grain size and concentration in ore slurries The extraction of raw minerals begins with the mining of rich ores which are then cut up in crushers and grinders The pieces of rock initially weighing tonnes are ground down to a few tenths of a millimetre... As a leading global manufacturer of crushing equipment, milling ...

CIPIN

Initially, the light mill only existed worldwide with the differentiation: hanging or standing light mills. But it was the company Cipin Glas that combined light mills with a wide variety of materials such as metal or wood for the first time and thus managing director and founder Andree Cipin today reports on several patents for various types of light mills.

Latest Posts

- الايجابيات المخطط الانسيابي ekstraksi بيراك

- طحن مصنع السودان للبيع

- مصانع صهر الحديد في كينيا

- الجزائر كسارة لا مثيل لها

- الصغيرة كسارة الفك المملكة المتحدة

- تكلفة آلة الكسارة في مصر

- تصنيع طاقة الجبس في الشركات في المملكة العربية السعودية

- استشارة كسارة الجبس

- المورد الحزام الناقل في الجزائر

- آلة سحق عظام البقر الأمازون

- معدات كسارة الفك في اليمن

- محطم قائمة الأسعار كسارة الحجر

- تستخدم معدات التعدين الذهب الجزائر سعر

- تكلفة سحق المعادن

- ما هو الأفضل مصر محطة كسارة

- Photos Of Smallest Rocksandmachine

- Supplier Of Used Coal Washing Plant Gabon

- Limestone Prospectivity Map And Indusrial Factors Using

- Walnut Crusher Machine Made In American

- Sand Processing Crusher Ton Price

- Impact Of Small Scale Mining

- Is There Ecocide During Coal Mining Crusher

- Shao Cor Jaw Crusher

- Penumbuk Batu Stone Crusher Mobile

- Filter Feed Pumps Rspecifications For Ro Plant

- Buy Wet Grinder Online In Honduras

- Great Coffee Grinders For Under

- Portable Crushing Mining Hp200

- Second Hand Cement Mill In Turkey

- Portable Chamfering Bevel Grinding Machine