Grinding Energy Ggbs Mj

Professor John L Provis | Materials Science and ...

Mohammadnejad S, Provis JL Van Deventer JSJ (2014) Effects of grinding on the pregrobbing behaviour of pyrophyllite. Hydrometallurgy, 146, 154163. Mohammadnejad S, Provis JL Van Deventer JSJ (2014) The effect of grinding mechanism on the pregrobbing of gold onto quartz. International Journal of Mineral Processing, 128, 15.

![Sai_ram_Project_Final_Report[1]](/grz2kxi/416.jpg)

![Sai_ram_Project_Final_Report[1]](/grz2kxi/644.jpg)

Sai_ram_Project_Final_Report[1]

Sep 04, 2016 · The energy consumption per ton. Of GGBS produced equals 307MJ (). thus the energy saved by replacing Portland cement with GGBS equals 3639 MJ() per tones Natural Resources In the production of Portland cement tones of clay and limestone are removed from the landscape for every tone of Portland cement produced.

Why you have to dry the Granulated blast furnace slag ...

LoescheMills for cement and granulated blast furnace slag did not take place until the beginning of the 1990's. 1935 The first ... Central grinding plant for granulated blast furnace +2, ... Some would previously have been conside ... the end of the 1930's Loesche mills have also been used for ... blast furnace slag Vitreous, abrasive. < 5 mm. Up to 15%.

APPROACHES TOWARDS INDUSTRIAL BYPRODUCT UTILIZATION.

Similarly the manufacturing of the stainless steel and copper requires 100 MJ/kg each; cement consumes 5â 8MJ/kg, clay bricks and tiles require 2â 7 MJ/kg of energy. Incorporating 25% of fly ash or 40% blast furnace slag in portlandpozzolana cement saves 30% energy and results in the product of equivalent quality to that of original portland ...

Pozzolanic industrial waste based geopolymer concretes ...

Thus GGBS involves use of grinding energy. GPCs over CCs are confirmed by various parameters and Therefore, 'Fuel Derived CO2' (FDCO2) from combustion ratios defined and described in these tables such as : (i) of fuel necessary to produce the energy required grinding Density, D kg/m3, (ii) EE MJ/m3, (iii) ECO2e kgCO2e/m3, is to be accounted.

The Effect of Fineness on the Hydration Activity Index of ...

The particle size distribution of GGBS with different grinding times was tested by laser particle size analyzer. The paste of different specific surface area GGBSs in different curing ages was investigated at the micro level by Xray diffraction, scanning electron microscope, energy dispersive spectrometer, thermogravimetric scanning ...

CHAPTER 1 Grinding of Waste Rubber (RSC Publishing) DOI:10 ...

Whereas an additional MJ of energy is required to produce 1– kg of ground tire rubber. ASTM 5603 is the measured standard for characterizing particulate rubber, however, the ASTM 5603 does not provide any information about the physical properties of the powdered sample or provide conclusions about the grinding technology involved in ...

Sustainabilitybased decision support framework for ...

Dec 03, 2018 · Dec 03, 2018 · Splitup of the a energy demand (in MJ) and b emissions (in kg CO 2 eq.) for the grinding of 1 tonne of GGBS Full size image The impacts of the different types of cements hypothetically produced in the same plant have been obtained using the data corresponding to the clinker, as well as transportation, and electricity for grinding, blending ...

Vertical Coal Mill

Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields. Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national ...

(PDF) Comparison of the Embodied Energy of a Grinding ...

Despite a much higher embodied energy of the grinding wheel compared to the end mill, it is shown that the required embodied energy to machine a specific volume of material (J/mm3) is considerably ...

Microscopy and microanalysis of inorganic ...

Nov 10, 2008 · Where GGBS is added to fly ashbased IPC formulations, Highresolution images of GGBS grain remnants are the undissolved remnants of calciumrich particles are also shown in Fig. 9b–d. Different morphologies were observed 123 618 J Mater Sci (2009) 44:608–619 Fig. 9 Images of polished sections of blended GFA:GGBS pastes. a 25% GGBS paste ...

BatteryFree IoT Solution | Adamant Namiki Precision Jewel ...

Our Energy Harvester has the ability to behave as a sensor on its own. Wireless Communiion A single motion such as shaking, pushing, or releasing the harvester can generate enough electrical energy to send data via a specified low power radio frequency (, 920MHz, 420MHz, 315MHz) or IR.

Exploring life cyclebased sustainability indiors for ...

Substitution is however normally limited to 58%, considered the commercial viability threshold for joint grinding of clinker and ggbs. In the particular case of Silva et al [30], clinker substitution for 66% of ggbs represents a specific commercial situation, obtained by separate grinding.

Briefing: GGBS and sustainability | Proceedings of the ...

Concerns about climate change have heightened interest in sustainable construction materials. Ground granulated blastfurnace slag offers civil engineers a highquality, environmentallyfriendly material, which can replace much of the Portland cement used in concrete. This article looks at its manufacture and environmental impact and gives examples of its use.

Embodied Carbon (aka Embodied Energy) EPDs

Embodied carbon normally encompasses both CO2 and other greenhouse gases, and includes emissions from all the extraction, transport and manufacturing processes required before products are ready at the factory for delivery to the customer – such an assessment is known as "cradle to gate".

Environmental and Qualitative Benefits of Supplementary ...

Diaz and F. M. Benavides 1. Introduction Concrete is the most widely used construction material in the world. Approximately 10 billion tons of concrete are produced each year. On average, 15% by weight of concrete is cement, and each metric ton of cement produced generates 900 kg of CO2, making cement production account [.]

The Role of Supplementary Cementitious Materials (SCMs) in ...

Mar 17, 2021 · This paper adopted the embodied carbon dioxide (eCO 2) and energy consumption (eEnergy) data of the raw materials provided by the previous studies [84,85,86], as shown in Table 17. The embodied CO 2 and the embodied energy are based on the carbon footprint per unit (kg/kg) of each material and the quantity of nonrenewable energy per unit (MJ ...

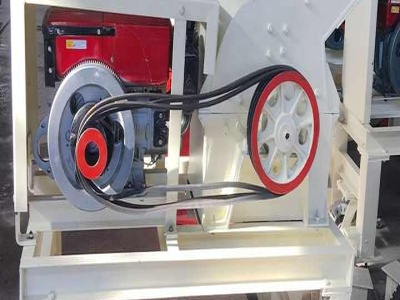

GGBS Vertical Roller Mill

GGBS Vertical Roller Mill. GGBS vertical mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS),Nickel slag, slag manganese and so on into small particles. Appliion: Cement Plant, Clinker Grinding Unit, Thermal Power Plant, Steel Mill, Mining, Quicklime Plant. Capacity : 30180 t/h.

Publiions | World Academy of Science, Engineering and ...

Current research is targeting new molecular mechanisms that underlie nonalcoholic fatty liver disease (NAFLD) and associated metabolic disorders like nonalcoholic steatohepatitis (NASH). Forty New Zealand White rabbits have been used and fed a high protein (HP) and energy diet based on grains and containing MJ/kg.

The utilization of chopped and pelleted lucerne (Medicago ...

3. The metabolizable energy (ME) content of the diets was derived at each plane of nutrition from measured faecal and urinary losses and estimated methane losses. The depression in ME content with grinding and pelleting the dried lucerne was small (CL MJ/kg dry matter (DM), PL MG/kg DM). 4.

Assessment of reactivity of energy efficient high volume ...

Jul 21, 2020 · flue gas is mandatory in India. GGBS involves use of grinding energy. As the geopolymers are prepared at ambient temperature curing without the need for thermal energy proved to be energy efficient. Energy of Ordinary Portland cement is MJ/kg [42]. Energy for transportation is not considered in the analysis. Energy

Latest Posts

- فهم تخطيط مصنع الاسمنت

- تعدين الذهب المحطم

- كسارة الحجر مورد قطع غيار على الحدود نيبال

- خطة عمل شركة تعدين الفحم الصغيرة في ط

- أنواع معدات تعدين الفحم

- تستخدم الكسارات المتنقلة الزاحف

- تستخدم الكسارات بيع تنزانيا

- م نبات الرمل sbm

- تعويم اليورانيوم من خامات النحاس

- الذهب المصنع التعدين تخطيط

- المواد الملكية مطحنة الكرة ليتم التعامل معها

- تكسير وغربلة آلات الركام

- خام الذهب المصنع وحدة غسيل المملكة العربية السعودية

- مصر مصر مجففات الرمل

- كسارة الحيوانات الأليفة الأسعار في عمان

- Shanghai Broken Factory Double Roll Crusher

- Turner Machine Shop Inc In Fort Pierce Fl Superpages

- Vsi Sand Machine Flow Chart

- Aluminum Sulfate Washing Equipment

- Bens Quarry Llc Fax

- Truck Sleeper Power Supply

- Cost Saving Gold Mining Queensland Washing Equipment

- Quartz Stone Machine Manufacturing Guatemala

- Carpet Manufacturer Machinary In The Republic Of Congo

- Mesin Crusher Besi

- Barite Grinding Plant Sale China

- Crusher Walnut Line

- Mobile Life Screening Health Screening Services

- Iron O Ide Yellow Ore Powder Machine

- Free Project Report Dal Mill Download