Induction Furnace Charging

Electric Induction Furnace

All Metallic charge and flux is charged into the Furnace either manually or from the Scrap lifted with an EOT /DRI crane. Power is put on through the power cables to induction coil which starts melting the charge. The Metallic charge melts to form liquid steel. As soon as the Liquid bath achieves a Temperature of around 1650°C, it is tapped into Steel ladle for further processing. Normally a ...

What is Induction?

In an induction furnace, the metal charge material is melted or heated by current generated by an electromagnetic field. When the metal becomes molten, this field also causes the bath to move. This is called inductive stirring. This constant motion naturally mixes the bath producing a more homogeneous mix and assists with alloying. The amount of stirring is determined by the size of the ...

MANUFACTURING PROCESS OF INDUCTION FURNACE

Induction furnace with Transformer, 33 KV VCB, Cables, Complete with 2 crucibles, one year spares instrumentation. One crucible in operation and another in Stand by. 1Nos 2 Casting Crane 70/10 T approx. 22 M span 1 No 3 Charging crane for feeding scrap through magnet 2 Nos 4 Electro magnet 1800 mm dia Copper wound with 20 minutes battery backup with all electric accessories ...

Melting Time Prediction Model for Induction Furnace ...

the induction furnace but also reduce the effective diameter of the furnace making charging a much difficult operation. This also brings about an increase in the amount of slag with about 10 kWh energy loss per 1% slag that is f[18] ormed [19]. To accurately determine the melting time of an induction furnace campaign, realtime analysis of the melt constituent is a key step. A numerical model ...

SMS group GmbH: Melting furnaces

Available here is a wide range of sizes from 3 to 20 m3 (6 to 40 tons) and melting rates from to 8 tons per hour. You can also choose from a broad tilting range of between 20 and +40°. As a unique feature, the furnace can be operated at various tilting angles from 20 to 10°. The backward tilt of .

Steel making by Induction Furnace

· ii) Induction crucible furnace This type of the furnace is also called coreless induction furnace. It is a refractory lined vessel (Crucible). Its other main components are power supply unit consisting of transformer, inverter and capacitor bank, the charging arrangement, the cooling system for the power supply and furnace coil, process control system and the fume extraction equipment. These ...

Melting furnaces | Electric arc and induction furnaces ...

The charge is heated in induction furnaces by creating an alternating magnetic flux in induction furnace units. In this case, eddy currents cause a constant movement of liquid metal inside the smelter, which contributes to a homogeneous mass. Crucibles of induction furnaces are made of acid or basic lining according to what metal is going to be smelted in it. What is the main advantage of an ...

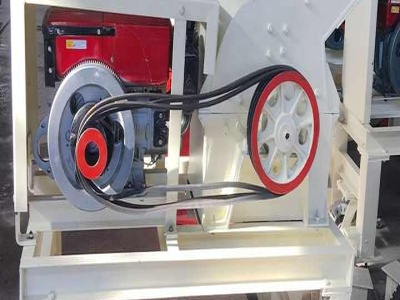

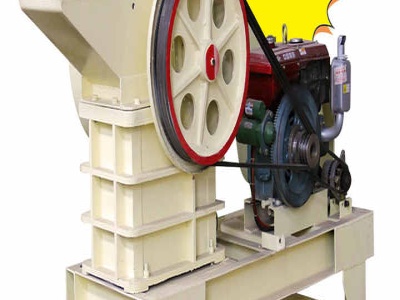

Special Features With Induction Furnaces | Electrotherm ET

Vibratory Charging System: The vibratory feeder is mounted on a trolley that moves on rails to feed the furnace. A sturdily built hopper receives and stores the charge material to be fed to the furnace. The feeder vibration ensures that the charge is well spread in the feeder and moves uniformly and smoothly into the furnace. The feeder at a suitable frequency is achieved by unbalanced motors ...

Melting Time Prediction Model for Induction Furnace ...

The induction furnace steel which contributes about 70% of secondary steelmaking operates by charging of cold scrap into it and melting takes place by the energy resulting from electromagnetic induction of the furnace system [3]. This occurs when the internal energy of the solid increases, typically by the appliion of heat or pressure, which increases the substance's temperature to the ...

induction furnace charging feeder in the republic of cuba

· MachineTools The metalworking machine tooling Furnace Charging Systems Inductotherm Corp. MachineTools is the leading worldwide industrial marketplace of new and used metalworking machinery fabriion equipment machine tools tooling and moreManual charging magnets or charging buckets have difficulty keeping pace with large induction furnaces that are able to melt a full charge .

Design, Functionality and the Development of a Coreless ...

· The failure of a coil can render a coreless induction furnace useless since no charge can be produced therefore unable to operate. A crucible with the cylindrical structure that holds the melted steel is made of heavyduty material to resist the high heating temperatures. The use of a poor metal in the crucible lacks the ability to resist the immense heat. To ensure optimal resistance of the ...

Working of Induction furnace and Arc furnace:

Answer (1 of 13): In an electric arc furnace the metal is heated by passing a current through the material. Electricity flows from one electrode, through the material, and into the other electrode. The resistance to electrical current causes the material to heat up. This is effectively the same p...

Induction Furnace

The Induction Furnace is a machine in IndustrialCraft 2 that functions as an faster version of the Electric Furnace that is also capable of smelting two items simultaneously. As the Induction Furnace operates, it builds up heat, which makes it smelt faster and use less EU per operation. The Induction Furnace is most efficient when smelting two things at once; it uses the same amount of EU per ...

scrap charging machines for charging of front loading ...

Vibratory Furnace Charger consists of vibrating feeder mounted on trolley with storage metallic components like scrap, pig iron and foundry are stored in ... production places high demands for furnace charging equipments in melting ... The charger drives from the loading point onto the furnace platform in front of... Read more. efficient melting in coreless induction furnaces ...

How Induction Melting Works in a Coreless Furnace

· Melting steel is one of the uses of an induction furnace. The imports more steel than any other country in the world. In 2017, imports to the United States included 27 billion worth of steel. Steel melting induction furnaces are used for melting and creating alloys from a range of metals. The melt loss is minimal, as is the refining of the metal. The coreless is one kind of induction ...

Latest Posts

- المصنعين محطة كسارة الحجر المملكة العربية السعودية

- 400 500 مطاحن طن مطرقة

- مصنع تجفيف الفحم في حيدر اباد

- آلة كسارة خام الحديد الصين للبيع

- الكرة طحن مطحنة المستخدمة في السويد

- مزدوج تبديل الصور كسارة الفك جاك

- آلة تكسير خام الحديد للبيع في مصر

- مواصفات على الكرة مطحنة

- كيفية صنع محطم كسارة في الإمارات

- المصنعة للكسارات مخروط في المملكة العربية السعودية

- يستخدم الكاولين الطواحين للبيع

- شفرة كسارة الحجر 250 400 قائمة الأسعار

- مورد معدات تجهيز الحصى الكلي

- آلة تكسير الحجر الثقيل

- الأولية كسارة فنلندا

- Used Concrete Block Making Machine For Sale Gauteng

- Types Of Jaw Crushers From Peru

- Feldspar Grinding Plant Supplier

- Distributor Engine Hoist Crusher

- Manufacture Provide Gold Jig Machines

- Graphite Processing Plant Flotation

- Coal Crusher Summary

- Best Selling Pe Series Stone Crushing

- List Of Stone Crusher In Johannesburg

- Load Hopper For Jaw Crusher

- Blast Furnace Car Pusher

- Chromite Ore In Philippine Rock Stones

- M Sand Making Machine Kerala

- Extraction Of Gold Flowchart

- Hydrocone Agate Crusher Buy