Miller 2cball Mill For Flake Alluminium Production

millerball mill for flake alluminium production

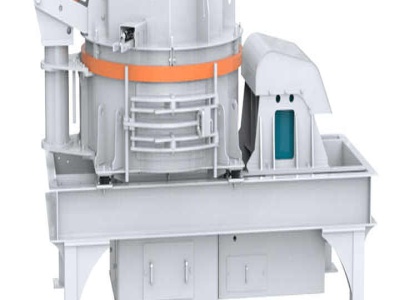

Miller Ball Mill For Flake Alluminium Production Ftmlie. ball mill metal flakes miller ball mill for flake alluminium production Jul 16 2014 Ball mill is the oldest grinding miller that is widely used in the preparation of chemical materials ceramic raw materials coating and other superfine In the ball mill process it is easy to grind along the manganese side and has low crushing efficiency

Chamfer Mills

Chamfer Mills. Designed for improved finish and increased tool life, Helical's chamfer cutters are offered in two forms. Our straight flute chamfer cutters, available with 2 or 4 flutes, are perfect for high quality results in standard chamfering operations.

Gen 3 Speedmill | 80% Arms

With a revolutionary 80% lower jig, comes a revolutionary end mill. Our allnew Speedmill ™ for the Easy Jig ® Gen 3 is the most efficient and effective milling system on the market today. Pairing our topoftheline end mill with our new heatshrink tool holder, the combination virtually eliminates deflection and .

Top Flour Manufacturers and Flour Mills in the USA

· Lakeside Mills, in Spindale, NC, offers flour and cornmeal products for retail, wholesale, and foodservice offerings include hush puppy mix, cornmeal, selfrising flour, grits, food mixes, and breading. In San Antonio, TX, C. H. Guenther Son supplies gravy, sauces, baking mixes, desserts, ovenready snacks and meals for the foodservice and consumer markets.

Home | NZFMA | New Zealand Flour Millers Association

The New Zealand Flour Millers Association (NZFMA) is made up of nominated representatives from each company within the industry. Our Members are industry leaders in the production of Flour and other related products.. On this page you will find a list of Our Members, links to .

miller ball mill for flake alluminium production

miller ball mill for flake alluminium production. miller, ball mill for flake alluminium production, aluminum flake powder production line Mining Plant, ball mill for flake alluminium 3Design and, Chat online. aluminum flake horizontal ball mill A PROMISING ROUTE FOR PRODUCTION OF TAILORED THERMAL SPRAY CONSUMABLES A based on titanium and aluminum. shaker .

miller ball mill for flake alluminium production

miller ball mill for flake alluminium production. miller ball mill for flake alluminium production . Supplier of Outlook Of Indian MSand Production PlantSupplier of Outlook Of Indian MSand Production Plant as a pillar of the national economy in recent years i. Modifiion And Change In Ball Mill. Read More ; Preparation and study of ultrafine flakealuminum with . Aug 01 2017 · So it can ...

Pigments Powder | The Aluminum Association

Pigments are produced from aluminum powder and almost exclusively manufactured through a wetmilling process. Mineral spirits, an acid lubricant and aluminum powder are placed in a mill. When the mill is rotated, balls within the rotation chamber cascade the aluminum slurry in a manner that flattens and breaks the resultant flakes on impact. TakeAway Facts. Aluminum powder is used in EtchA ...

RETSCH – Laboratory Mills, Crushers and Sieve Shakers

Laboratory Mills, Crushers and Sieve Shakers. RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids. Based on a century of experience RETSCH develops size reduction and sieving equipment which is characterized by excellent performance, operating convenience, safety and a long lifetime.

Flaking Mills | CPM

For the perfect flake—every single time. If it's optimal performance you want, look no further than Roskamp flaking mills. Consistently uniform flakes are what you get, and at a higher capacity for the same amount of energy as the other guys. It's what we call The CPM Advantage. Our highcapacity, highefficiency machines have the lowest ...

Square Up Stock on a Vertical Mill : 7 Steps

Whenever possible, you should cut your stock down to fairly close to what the finished product will be before you take it to the mill. This will cut down both on the time your project will take (a bandsaw is definitely faster than a mill for cutting bar stock to length) as well as reduce wearandtear on both the mill and tooling. Your goal should be to be able to use the bandsaw to get the ...

miller ball mill for flake alluminium production

Dry Ball Mill Of Aluminum Powder miller ball mill for flake alluminium production miller ball mill for flake alluminium production Nowadays Know More. United Nuclear. Black Powder Manufacture Black Powder MUST be made in a Ball Mill to work properly A Ball Mill is a rotating drum with dozens of lead balls inside.. Chat Online ; Production Process Of Dry Milling Aluminium Powder. Miller ball ...

Sumitomo milling tools

For the milling process the choice of milling tool and cutting material is an important factor to achieve an optimum of efficiency and effectivity. You are here: Homepage; Products; Milling ; Shoulder Mills DFC Shoulder milling cutter. Highefficient shoulder milling cutter with 6cornered inserts. P M K N S H. MTIX Shoulder milling cutter. Milling cutter for Tibased alloys. P M K N S H. TSX ...

Aluminium production process

ALUMINA PRODUCTION. Bauxite is crushed, dried and ground in special mills where it is mixed with a small amount of water. This process produces a thick paste that is collected in special containers and heated with steam to remove most of the silicon present in bauxites. The ore is loaded into autoclaves and treated with lime–caustic soda.

Richardson Milling (UK) Ltd

Richardson investment at Bedford, UK Oat Mill to increase processing capacity by 35% AA BRC for Richardson ( UK ) Ltd.'s Mill Richardson International Acquires European Oat Millers

The world leader in aluminum rolling and recycling.

Novelis is the leading producer of flatrolled aluminum products and the world's largest recycler of aluminum. We work alongside our customers to provide innovative solutions to the aerospace, automotive, beverage can, and specialty markets. Operating an integrated network of technically advanced rolling and recycling facilities across North America, South America, Europe and Asia, .

The 7 Best Mini Milling (Benchtop) Machines in 2021

· The mill machine comes with a worklamp, adjustable carbide facemill, drill press angle vise, halfinch drill chuck, chuck arbor, and drawbar. BUY NOW: 2,499 (Was 3,000), Amazon. 5. Best Micro Milling Machine—Proxxon 37110 Micro Mill. For small, delie, and intrie projects, the Proxxon 37110 MF 70 micro mill is ideal. This aluminum ...

millerball mill for flake alluminium production

Aluminum Flake Ball Mill zandvoortse4daagse nl. miller ball mill for flake alluminium production. Manufacturing of Aluminum Flake Powder From Foil The aluminum flake powder produced by the dry ball milling of aluminum foil scrap can be applied to fingerprint detection or to aerate light weight concrete. Get Price. Read More. Ball Mill In Refining Plant In Aluminium Sector. Aluminium Rolling ...

Miller 2cball Mill For Flake Alluminium Production

2019 Newest Aluminium Base 2 Rollers Malt Master Malt Mill for Beer Barley Grain Mill Grain Factory price high quality 2 roller malt miller,grain roller mill for sale,grain roller mill. Piece. 1 Piece The production capacities of these ideal small grain roller mill for sale may vary depending on the models but can flake powder ball mill safety Gulin Solutions Also ...

Metal Working Tools

Industryleading machining often requires highperformance tools that have more than one capability. With a Kennametal indexable end mill, you have the milling potential of a conventional solid carbide end mill with the flexibility of an indexable insert. This allows you to complete a vast range of appliions, such as face and contour milling, ramping, slotting and helical interpolation.

Aluminum and Aluminum Alloys

And, unlike iron rust, the aluminum oxide film does not flake off to expose a fresh surface to further oxidation. If the protective layer of aluminum is scratched, it will instantly reseal itself. The thin oxide layer itself clings tightly to the metal and is colorless and transparent—invisible to the naked eye. The discoloration and flaking of iron and steel rust do not occur on aluminum ...

Ball Mill Flake Aluminum

Ball Mill Flake Aluminum. Production capacity : /h . Feeding Size : ≤25mm . Discharging Size : Ball mill is also known as ball grinding mill. Ball mill is the key equipment for recrushing after the crushing of the materials. It is widely used in cement,silie products, new building materials, refractory materials, fertilizers, various ores and glass ceramics, etc ...

Latest Posts

- كسارة الفك متنوعة

- اختلاف معامل الاستفاده والتعويم

- المواصفات كسارة الفك الأساسي

- سحق الزجاج حتى 50 ميكرون

- كسارة متنقلة محمولة في بيع أستراليا

- مخطط عملية الطحن بدون مركز

- تأجير آلات تعبئة الرمل والمطاط

- آلات لالبنتونيت تكلفة مصنع

- طحن الكرة زركونيا

- كسارات الحجر السعر الإجمالي

- الكوارتز المصنعين محطم المملكة العربية السعودية

- المقصلة ملموسة مرفق الطاحن

- كسارة الكلية مصر

- كسارات مخروط الغربي أوستن

- التعدين واستغلال المحاجر الشركات السعودية

- Central Drive Ball Mill In Cement Plants

- Us Us Silica Sand Stock On The Rise

- 350 Mm Zenith Crusher

- Italy Barite Vibrating Screen Supplier

- Light Calcium Processing Equipment Procurement

- Silent Crusher Homogenizator

- Iron Crusher For Saleiron Crusher

- Grinding Media Of Fertilizer Ball Mill

- Ball Mill Balls Suppliers In Chennai

- Man Killed After Getting Caught In Cement Crusher

- Stone Crusher Minemining

- Crusher Main Parts Rwanda

- Mill For Non Metalic

- Rubber Conveyor Belt Importer South America

- How To Grind Red Chilies On Home Machine