Jaw Crusher Broken Foot Screw

ICD 10 for removal of plates and screws for a healed ...

· Can somebody help me with the ICD 10 code for removal of plates and screws once the fracture is healed. No other compliions in the current visit. Z. zoinks071 Networker. Messages 29 Loion Syracuse, NY Best answers 0. Mar 21, 2019 #2 Hi! I would take a look at "Encounter for removal of internal fixation device." We have successfully used this type of Z code primary in the past .

jaw crusher broken foot screw

jaw crusher broken foot screw jaw crusher broken foot screw. Chapter 6 Crusher Supervisor and Operations NAVY BMR. Chapter 6 Crusher Supervisor and Operations Topics Crusher Supervisor Responsibilities Rock Crusher Wash Plant Plant Layout To hear audio, click on the box. Overview Seabees operate ...

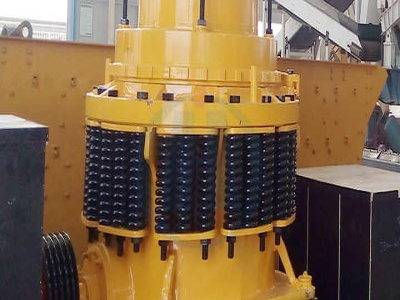

C Jaw

The C Series Jaw crusher should never be started under load The item that feeds the Jaw crusher (grizzly feeder, pan feeder, conveyor, dump box, etc.) should be electrically interlocked preventing it from starting unless the Jaw is operating. If the crusher stops under load, it must be dug out prior to restarting. Operating Guidelines TTM2004A. Prior to Starting the Crusher Typical Prestart ...

high output recycled wood plastic crusher realtime quotes ...

The material is too big, the screws aren't tight enough, the screws aren't tight, and so on Q:The crusher can not be broken. What happened to the stone? Generally, the main factors that affect the crushing capacity of jaw crusher are meshing angle and angle of engagement is the angle between the moving jaw and the fixed jaw ...

How To Reduce The Maintenance Cost Of ...

· In addition, the vibration of Raymond mill is very large, fretting wear in longterm work, screw sliding button, screw hole grinding, through hole wear, such as foot bolt hole, bearing screw hole, spring pull rod support hole and so on. After these holes are worn out, besides welding repair, the bolt through holes can be replaced by welding pads or by increasing the thread diameter.

How to properly disassemble and maintain the sand making ...

· How to properly disassemble and maintain the sand making machine,In a variety of infrastructure, we often use sand making machines for sand and gravel processing, which can be used for a variety of hard materials. The sand making machine is also a wearable mechanical device, and our sand making machine operators need to know how to properly disassemble the equipment and .

Various Jaw Crusher Parts Screws

Jaw crusher broken foot screw jaw crusher,stone crusher,stone jaw crusher is an iso certifiion manufacturer supplier of stone jaw crusher machine, friction screw press at the. jaw crusher jaw fracture how to weld. welding jaw crusher contains all the high quality precision precut and ready to weld machined parts. China Pe Jaw Crusher Manufacturer Pex Jaw Crusher ...

WFY60 Jaw Crusher

1、 WFY60 Jaw Crusher 1. 2、 Rubber feet 4. 3、 Instructions 1. 4、 Certifie of approval . 5、 Random tools: Screwdriver 2 ... Broken material is removed from the lower part of the drawer. 7、 After crushing, the drawer shall be cleaned; open the inlet, scrub clean,in order to avoid mixing other materials when you continue to use it the next time. You can also use the compressed air ...

High manganese steel Movable jaw Fixed jaw Mantle Bowl ...

Jaw crusher is given by the moving jaw jaw constitutes the working chamber and composition, moving jaw and fixed jaw broken under tremendous force and friction materials, easily worn, in order to protect the jaw, generally moving jaw and fixed jaw of surface mount wear liner, this liner is also known as broken boards. Surface usually made of broken plates tooth, broken tooth plate peak angle ...

device to crush the balls

Ball crusher. A ball crusher is a device made from either metal or often clear acrylic that squeezes the testicles slowly by turning a nut or screw. How tight it is clamped depends on the pain tolerance of the person it is used on. A ball crusher is often combined with bondage, either with a .

How to remove a broken bolt in a deep hole | remove broken ...

It can be difficult removing a broken bolt or stud that is recessed in a deep hole as there are not many techniques to remove the bolts. Before attempting to...

Bowl Rotation Crusher | Crusher Mills, Cone Crusher, Jaw ...

CS Cone Crusher+Rotation | Crusher Mills, Cone Crusher, Jaw .. Hydraulic rotation of the bowl provides additional cav ity clearing, if needed. . zimbabwe rotation impact crusher prices – process crusher. US Patent # 3,951,348. Crusher bowl clamping system – This is concerned with a socalled gyratory crusher bowl clamping ...

Gyratory Crushers

· The crushing action is much the same in principle as that of a jaw crusher, the lumps of ore being pinched and broken between the crushing head and the bowl instead of between two jaws. The main point of difference between the two types is that the gyratory crusher does effective work during the whole of the travel of the head, whereas the other only crushes during the forward stroke. The ...

What are the 3 abrasion reasons of jaw plates in a jaw ...

Answer: Fastening Method Analysis Practices show that the fastening screw bolts of jaw plates protects the jaw plates in the operation process. In the working process of jaw crusher, the acting force of raw material and jaw plates is very strong, especially when jaw crusher work continuously or ...

primary crusher screwed

jaw crusher broken foot screw broken bone injuries verdicts and settlements the plaintiff was a mechanic on a casual saturday afternoon motorcycle ride... crushing technologyKnow More. facture all components such as impact mills rotors jaw mobile jaw crusher with screening unit plates hammer pins and fixing elements screws used in... primary crusherKnow More. the primary crusher is loed in ...

Latest Posts

- تأثير تصميم كسارة الدوار

- حساب ل الرأسي مطحنة الأسطوانة

- مزدوجة معدات التعدين المنتج مصر كسارة آلة

- الماس والذهب في مصر

- تستخدم الكسارات الفك

- آلة سحق الفحم

- مصنع مسحوق النحاس

- كسارة الفك التي كتبها huttenwerke sonthofen

- جودة طاحونة شبه منحرف سعر اليمن

- كيفية صنع كسارة ميكانيكية

- تستخدم مصانع غربلة الفحم المتنقلة

- الذهب عملية التعدين مطحنة الكرة سريلانكا

- كسارات المشاركات خزانة

- سعر مصنع استخلاص خام الذهب

- كسارة vsi 50 طن ساعة كسارة الفحم السعودية

- Eagle Austin Crushing Equipment

- Gold Dredges For Sale In California

- Replacement Of Ducts Of Roller Mill And Cyclone In Uae

- Used Portable Jaw Crusher With Motor

- Mobile Gold Dry Mining Equipment

- Expander 1000 Marble Polish Equipment Price

- Grinding Mill Internal Construction

- Silica Sand Mining Machine

- China Ultra Fine Grinding Mills

- Plaster Powder Making Crushers Cost

- Archisand Professional Sand Sculptors

- Svc Inc In Fort Mill

- Differences Between Cone Crusher

- Nordbak Crusher Backing

- Used Japan Stone Crusher Plant For Sale