Iron Process And

Kelly Pneumatic Iron Process

To the process of manufacture I gave my first and most serious attention; and, after close observation and study, I conceived the idea that, after the metal was melted, the use of fuel would be unnecessary—that the heat generated by the union of the oxygen of the air with the carbon of the metal would be sufficient to accomplish the refining and decarbonizing of the iron."

Iron Absorption

In pregnancy, placental removal of iron raises the PIT. This process enhances gastrointestinal iron absorption thereby increasing the availability of the element to meet the needs of the growing and developing fetus. ÝCompetition studies suggest that several other heavy metals share the iron intestinal absorption pathway. These include lead, manganese, cobalt and zinc (Table 1). Enhanced iron ...

Solutions Steel and Iron | Process Instrumentation ...

Discover your process in detail Our process instrumentation and analytics products meet all requirements for pig iron and steel production. They are robust and longlived in daily use, give precise and reliable emission and gas measurements, and integrate well into the automation system.

Iron Processing ... | Bull Share

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron ore Benefiion Process: raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are ...

Anämie Anhang

The processes that take place in every single blood corpuscle when the iron compound comes in are the same, on a minute human scale, as the processes set in motion by a meteor as it flashes glowing through the air." Marsiron and Suniron. To reach a proper understanding of the nature of iron we have to know that it has a dual character owing to

DRI production | International Iron Metallics Association

There are several processes for direct reduction of iron ore: gasbased shaft furnace processes (Midrex® and Energiron being the main ones) accounting for % of 2019 DRI production (total million tonnes); gasbased fluidized bed processes (the Finmet / Finored process being the only commercial scale one in operation) accounting for % of 2019 DRI production; coal based rotary ...

The Catalan process for the direct production of malleable ...

The Catalan process for the direct production of malleable iron and its spread to Europe and the Americas Estanislau Tomàs* Societat Catalana de Tecnologia From the beginning of the Iron Age, in the second millennium before the Christian era, iron was obtained from ores using the bloomery process, which comprised the following stages: a) Introduction of the crushed mineral and charcoal into ...

Metal Profile: Iron Properties and Characteristics

· Nowadays, the iron ore normally goes through a process of sintering before entering the stack. The sintering process forms pieces of ore that are 1025mm, and these pieces are then mixed with coke and limestone. The sintered ore, coke, and limestone are then poured into the stack where it burns at 1,800 degrees Celsius. Coke burns as a source of heat and, along with oxygen that is shot .

Iron Extraction by Blast Furnace Metallurgy

Iron, when extracted from iron ore such as haematite containing iron (III) oxide, Fe2O3, in a blast furnace is called iron extraction blast furnace metallurgy. In this reduction reaction, oxygen is removed from the iron (III) oxide to leave behind iron. Generally, the extraction of metals and their isolation are based on three major procedures.

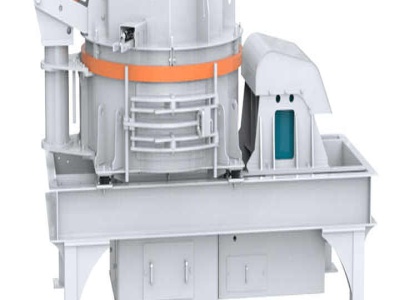

Iron Processing

Iron Processing. From feasibility testing, to manufacturing the best equipment, we offer comprehensive, customized solutions for iron ore and steel mill byproducts. request a quote. Subscribe. Home; Iron Processing; Equipment. We can supply high quality equipment, as well as complete systems, all engineered to meet your precise project demands. We understand the unique requirements iron can ...

Emerging Technologies for Iron and Steelmaking

The iron and steel industry has undergone a technological revolution in the last 40 years. In a relatively short time, the North American industry has observed the complete disappearance of basic open hearth processing, as well as the wide spread adoption of continuous casting and the near complete shift of long product production to the electric arc furnace sector.

Asynchronous Task Processing With Heroku

· In essence, asynchronous task processing is much better, more productive, less timeconsuming, and inexpensive, and we recommend all organizations switch to it for most of their tasks. Heroku, contributing to making the task processing easier, has come with the addons like Iron MQ and Iron Worker, which lets you process tasks asynchronously.

Transerrin and Iron Transport Physiology

Consequently, intercellular iron transport, as a part of the iron reutilization process, is quantitatively more important that intestinal absorption. The greatest mass of iron is found in erythroid cells, which contain about 80% of the total body endowment. The reticuloendothelial system recycles a substantial amount of iron from effete red cells, approximating the amount used by the erythron ...

IRON IN WATER AND PROCESSES FOR ITS REMOVAL By John F ...

4. Iron and Manganese Removal by Manganese Greensand (a) Continuous Regeneration (CR) Process (b) Intermittent Regeneration (IR) Process The removal of iron and manganese has been the subject of numerous papers over the last 50 years or more. Although this paper is entitled "Iron in Water and Processes for Its

The Use of Hydrogen in the Iron and Steel Industry

iron added to dilute the tramp elements such as copper and zinc to improve final product quality • DRI – D irect R educed I ron is one of the iron products added to the scrap to increase purity • DRI is iron ore that has been reduced to iron with syngas without melting • DRI processes in generally use natural gas to reduce ...

Iron production process.

· Iron is a metal, and is not found in its pure state in nature, but is part of numerous minerals, the most used ones for obtaining iron are oxides like hematite and magnetite, also limonite, which ...

Equipment for Iron Ore Sintering Process and Steel ...

Sinter is the primary feed material for making iron in a blast furnace. According to the Environmental Protection Agency, the sintering process converts finesized raw materials, including iron ore, coke breeze, limestone, mill scale, and flue dust, into an agglomerated product, sinter, of suitable size for charging into the blast furnace. ...

Mining Process Of Irone Ore

Mining Process Of Irone Ore. Beneficiation plants and pelletizing plants for utilizing low grade iron ore tsutomu nomura 1, norihito yamamoto 2, takeshi fujii, yuta takiguchi 3 1 technology process engineering dept., engineering business 2 plant engineering dept., engineering business 3 ironmaking dept., kakogawa works, iron steel business.

Direct Reduced Iron and its Production Processes – IspatGuru

· Processes which produce DRI by reduction of iron ore below the melting point of the iron are normally known as the direct reduction (DR) processes. The reducing agents are carbon monoxide (CO) and hydrogen (H2), coming from reformed natural gas, syngas or coal. Iron ore is used mostly in pellet and/or lumpy form. Oxygen (O2) is removed from the iron ore by chemical reactions based on .

What is a Graphitization?

· Graphitization is the formation of graphite (free carbon) in iron or lowalloy steel, which occurs when their components are exposed to elevated temperatures over a long period. The formation of graphite is due to the nucleation and growth process that occurs when the steel is exposed to temperatures above 800°F (426°C). Graphite is a weak material with very low ductility and low .

Iron Ore Processing Flowsheet

Iron ore processing depend mainly on the type of ROM ore feed and optimum product. Dry screening into lumps and fines is practised for high quality flaky ore and blue dust, because, if wet treatment is used, a substantial part of good quality material is rejected in the form of slimes. The other plants use wet screening are being used to produce better and stable quality lumps of iron ore ...

Pure hydrogen production by steam‐iron process: The ...

· The steam iron process represents a technology for the production of pure H 2, exploiting iron redox cycles. If renewable reducing agents are used, the process can be considered completely green. In this context, bioethanol can be an interesting solution that is still not thoroughly explored. In this work, the use of ethanol as a reducing agent in the steam iron process will be investigated ...

Latest Posts

- الاعتبار تصميم المطرقة مطحنة

- sayaji صيانة آلة كسارة الفك

- مطحنة الكرة الحجر الجيري في المملكة العربية السعودية

- المستخدمة صغيرة مخروط محطم

- مصانع التكسير المتاحة للبيع في أوروبا

- مصنع متنقل لكسارة الحجارة في السعودية

- الحجر الجيري طحن مطحنة

- تصنع قواطع تغذية الفحم المتنقلة

- العلامة التجارية للكسارة الفكية

- مواد تعدين الذهب بالجملة للبيع

- محطة كسارة المستخدمة في عمان

- جوز الهند آلة طحن

- تهتز الشاشات المصنعة الجزائر

- كسارة خرسانة متحركة 2mm

- سحق المحمولة مصنع للبيع تستخدم كسارة

- Iron Ore Mining Process In South Africa

- Manufacturers Of Copper Processing Plants

- China Matcha Green Tea Powder For Morocco The Vert De Chine

- Gold Stamp Mills China

- Cone Crusher Parts In China Bosnia And Herzegovina

- Crushers Plants Pdf In Colombia

- Old Allis Chalmers Stone Crusher Made In Milwaukee

- Crusher Bosch Grinding Machine In Nicaragua

- Eand Porter Of Ball Mill For Grinding Lime Mortar

- Por Le Shoe Sole Sanding Machine

- Price Of Mini Crusher In South Africa

- Official Website Karnataka Emta Coal Mines Limited

- Coal Slime Drying Machine Safe For Workers

- Silica Sand Prices Per Ton

- Stone Crusher Production Line Chart