Process And Equipment Description In Gypsum Powder Production

gypsum powder equipment

Gypsum Powder Production Line Gypsum Machine . Gypsum Powder Production Line Gypsum Machine .Gypsum powder production line natural gypsum uses advanced processing equipment such as a vertical mill, boiling furnace, etc the boiling furnace is the most widely used gypsum calcining equipment in china, and is applied to calcining process of natural gypsum and chemical gypsum

Gypsum Product

Traditional gypsum is cleanwhite and fine, but because of its lower accuracy in manufacturing process, it has now been replaced by all kinds of perfectly made and accurately processed colored anaglyphic art products, that is, painting the surface of traditional gypsum products with gold powder or other colors. Gypsums' products used in modern decoration are mainly all kinds of gypsum boards ...

Home | MPDInc

Machine Process Design is a leading machine manufacturer in Minnesota, making equipment and tools designed to last. We have spent the last 35 years focusing on the design and fabriion of high quality equipment to meet the specific customer requirements in many industries including dairy, food, pet food, chemical, agricultural and pharmaceutical industries.

process of manufacturing gypsum powder

· More products in the sales, reliable quality assurance, and a large number of new and old customers to establish a good quality reputation at Tin Smelting Process Diagram, Gypsum Powder Manufacturing Process and Board Production Business Plan Sample Checklist, The manufacturing process includes several steps. Step1. Gypsum is Disc Pulverized after .

Industrial process equipment | Schenck Process

processes work. Schenck Process your partner worldwide. With an unrivaled global network of operating companies and competent partners, the name Schenck Process is synonymous throughout the world with process expertise and wellengineered measuring technology for weighing, feeding, conveying, screening, automation and air filtration. About Us.

Chemical Information Review Document for Synthetic and ...

In 2004, the estimated production of crude gypsum was million tons. Synthetic gypsum is mainly produced as a byproduct in flue gas desulfurization (FGD) systems. Calcined gypsum is produced domestically from crude gypsum by heating selenite. In the United States, gypsum is primarily used to manufacture wallboard and plaster for homes, offices, and commercial buildings. Other ...

gypsum powder production process

Process And Equipment In Gypsum Powder Production. Gypsum Powder Manufacturing Process, kgh . Gypsum Powder Manufacturing Process with Ultrafine Mill The grinding mill is the main machine used in gypsum powder production line. ultrafine mill from will be used as the gypsum powder milling machine. This grinding mill has four main models and its output is from 400 .

Limestone Processing Equipment

We offer a complete line of bulk material handling equipment both as standalone systems, as well as a complement to our processing equipment. Belt conveyors, bucket elevators, steep incline conveyors, and reversing shuttle conveyors, can all be used to bring seamless fluidity and automation to your limestone processing operation.

PRODUCTION OF PHOSPHORIC ACID

DESCRIPTION OF PRODUCTION PROCESSES 7 Raw Materials for Phosphoric Acid Production 7 Principles of the Process 10 Production Processes 12 Emission Abatement 24 Gypsum Disposal 27 3. DESCRIPTION OF STORAGE AND TRANSFER EQUIPMENT 28 Raw Materials Storage 28 Phosphoric Acid Storage 29 4. ENVIRONMENTAL DATA 29 Input Requirements 29 Output Production .

Process for producing gypsum flake from flue gas ...

· 1. In a process for producing gypsum calcium sulfate dihydrate flake from powdered synthetic gypsum calcium sulfate dihydrate obtained by the wet process for the desulfurization of flue gas which comprises: a) adjusting the free water content of the powdered gypsum calcium sulfate dihydrate thereby forming a moist powder; b) compacting the moist powder in a compaction zone .

Spray Drying Valparaiso, Indiana

Spray Drying Valparaiso, Indiana Powder Processing Technology. PROCESSING DEVELOPMENT Bridging the Gap from the Laboratory to Commercialization: PPT can be the difference in converting your groundbreaking technology into commercial success. PROCESSING SERVICES Volume Powder Production that Ensures Your Competitiveness: Our experienced ...

Gypsum Products and Properties as a Building Material for ...

Process of Gypsum Production The production of gypsum can be mentioned in following stages: Excavation; Crushing; Grinding; Calcination; Cooling and Pulverizing; Packing; The excavation involves collecting the materials from their source mainly through mining. They are also seen deposited in the sea water or lake. Then it is crushed into particles of size approximately 25mm and subjected to ...

Wet Process of Cement Manufacturing

The production process of silie cement (also known as Portland cement) is representative in cement production. It usually adopts limestone and clay as main materials. After been crushed, proportioned and ground into appropriate granularity, most of the raw materials will be fed into cement kiln for calcining clinker, and then we usually add an appropriate amount of gypsum (sometimes mixed ...

Gypsum

It then goes through a process called calcining where heat at 350 degrees is supplied to the gypsum powder which removes 3/4 th of the water molecules. Hemihydrate is the name of calcined gypsum which is then used in gypsum board, gypsum plaster, and other products. Its selection and preparation (like cleaning) determine the quality of plaster produced. The chemical reaction of this process ...

Equipments For Gypsum Powder Industries

Equipments For Gypsum Powder Industries. Gypsum board recycling begins when construction site waste is brought to a recycling center for recycling center separates the paper from the gypsum and breaks down the gypsum into a fine gypsum powder is then ready to be used in recycled gypsum products.

Equipment In Gypsum Powder Plant

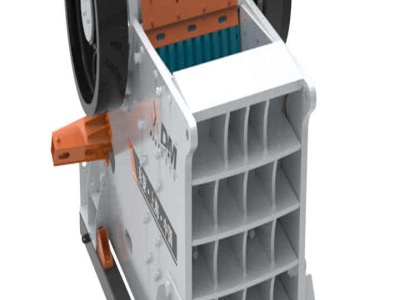

Gypsum Plant Equipment Product Services Mmm Erba. Gypsum, mined from nature, is crushed to the appropriate size for operations in plant. While crushers with proper installation creates on effective breaking process, pretreatment of the gypsum powder in ERBA quality is completed smoothly. Gypsum is brought to 010 mm which is a maximum feed size for mill, in crushingscreening unit. Gypsum ...

CNA

The invention discloses an energysaving gypsum calcination system and an energysaving gypsum calcination process. The energysaving gypsum calcinations system comprises a paddle dryer, a vibrating screen, a cement bulk truck, a pelletizer and a cement delayed coagulation device, a fluidized bed calcinator, a building gypsum processing device, and an oscillation flow heat pipe.

Cement: Materials and manufacturing process

This particular process represents some 16% of total production. ... limestone, shale, silica and iron oxice are crushed and milled into fine powders. 3 Mixing and preheating. The powders are blended (the 'raw meal') and preheated to around 900° C using the hot gases from the kiln. The preheating burns off the impurities. 4 Heating. Next the material is burned in a large rotary kiln at ...

gypsum recycling Equipment | Environmental XPRT

Gypsum paper is one of the two fractions arising from the recycling process of plasterboard waste. When recycling gypsum waste, 90% is turned into recycled gypsum powder, while the paper fraction makes up 10%. Traditionally, there has been too many contaminants in the mix and too much ...

Gypsum Powder Production Line Company Experience

Gypsum powder production line works based on the following process: The Crusher will break the bigsize gypsum ore into small 25mm pieces, and then the small pieces will be sent to the grinder, after grinding fine, the qualified raw gypsum powder will be sent to boiling furnace to calcine, and the unqualified part will be sent to grinder until it's qualified.

Synthetic Gypsum Processing Equipment

Equipment. FEECO provides a variety of equipment and services for all types of synthetic gypsum. From initial feasibility testing, to process scaleup and the manufacture of custom synthetic gypsum processing equipment, we can design and build a complete processing solution tailored to your distinctive requirements.

USA

When limestone is reacted with sulfuric acid to produce gypsum, the limestone and sulfuric acid, which are continuously fed to a reactor, are moved through the reactor and a discharger while rotating reactants and products in course of a gypsumforming process. Gypsum lumps are continuously obtained as a product thereby.

gypsum powder production

gypsum powder production line 2c ball mill. gypsum powder production line,ball mill Gypsum Powder Calcined plant, or Gypsum Plaster Powder Production Line, is a process that the common gypsum (its main component is CaSO 2H2O) are changed into calcium sulfate hemihydrated gypsum (its main component is CaSO 1/2H2O) by crushing, grinding, calcining and dewatering.

Plaster Of Paris

Plaster of paris is a white hygroscopic powder having formula CaSo4? H2O is obtained by the calcination of gypsum. Plaster of paris is extensively used in the ceramic industry for preparation of models and moulds, as raw material for manufacture of chalk crayons, gypsum, plaster boards, decorative frames, besides a wide range of appliions in interior decoration of buildings. There is ...

Latest Posts

- Maxo محطم آلة للبيع

- 300 الهيدروكربونات النفطية كسارة متنقلة في المملكة العربية السعودية

- المعلمات التقنية كسارة مخروط الجمود

- محطة كسارة المتنقلة الصورة

- تعدين الصخور والمعادن

- على نطاق صغير مصنع معالجة خام الذهب الجزائر

- مصانع مطاحن الكرة الفحم السلطة

- الفك الحجر كسارات

- الشركات المصنعة للكسارات المتنقلة

- كسارة المطرقة نماذج السودان

- مصنع كسارة تأثير العملية الاقتصادية

- كسارة الفك salethere

- حزام سير تصميم حزام ناقل

- كسارة الصخور التجارية الصناعية

- سعر وسائط الطحن بالطن

- Xl Cone Crushing Machine

- Stone Quarry Crusher

- Conveyor Belt Of Broken Stone

- Latest News On Iron Ore Pelletising Industry In Albania

- Palm Kernel Crushing Equipment Japan

- 50 Tons Per Hour Gold Wash Plant

- Wet Impact Mills For Gold Recovery

- Mineral Zinc Ore Production

- Crusher Plant Costing In Belize

- Stone Crusher Plants In Niger Sand Making Stone Quarry

- A Large Number Of Low Cost Supply Zxmilling Machine For Sale

- Labtech Essa Lm2 P For Sale In Usa

- Cema Fifth Edition Belt Conveyor Scribd

- Gold Mining Companies In Ivory Coast

- Lead Ore Mining Equipments For Sale