Bevel Gear Grinding Model

Analysis and modeling of error of spiral bevel gear ...

· Journal of Central South University Sixaxis numerical control spiral bevel gear grinder was taken as the object, multibody system theory and .

AN OVERVIEW OF GEAR MANUFACTURING PROCESSES

In front wheel models, hypoid gears have been replaced by helical gears. Fig. shows a typical transaxle of front drive model. Involute splines, both external and internal, are also widely used on various shafts and hubs for slide meshings in transmission system. Bevel gear and pinion are still used in differential of automobiles. However, parallel axes spur and helical gears are the main ...

gear grinding 1200mm

IndiaMART Manufacturing Assembling Services Grinding Services Gear Grinding Services Gear Grinding Job Work Get Latest Price Power 2HP Voltage 240V Frequency 50 60Hz weight 5500 Kg Size 4000 x 1400 x 1200mm View Complete Details . MFG 3540 220G Gear Form Grinding Machine – Matrix. I E temperature control between 20°C 26°C±1°C will achieve gear Grade 4 to DIN 3962 and .

Bevel gear sets | Further Components | Products | Flender

FLENDER Bevel Gear Sets: Total Precision. Expertise and Quality Production in the Customer's Interest. As a manufacturer of geared parts for use in industrial and industryrelated drive systems we grind or lap bevel gear sets or make them according to the HPG method. Owing to our farreaching expertise in gear units and our industryspecific knowhow that has been growing over decades we ...

spiral bevel gear grinding stock

The spiral bevel gear model is made of three basic with evident limitations. A major shortcoming is nonuniform stock removal which may even cause portions of the casehardened layer to be swept away or conversely parts of the tooth surface may not be finished at all by the grinding wheel. it was revealed during the investigation . Read More; Gear GrindinGNorton Abrasives. sPiraL BeVeL Gear ...

Bevel Gear Grinding Model 5a872

Bevel Gear Grinding Model 5a872. Surface grinding copper ProForums. Mar 26, 2006 For a 1 off, get your copper block flat, with hammer or lathe etc., and get some 6mm or 14 dead soft pure aluminium sheet 30cm x 30cm, some thicker cloth such as felt or windcheater material to carry the sheet and some chip board to carry the lot then use some automotive valve grinding paste, then rub the copper ...

bevel gear

4014t Bevel gear for Wlt... by andi afsd. 2 37 0. AutoCAD, STL, Rendering, August 7th, 2021 bevel gear. by Mohammed Faizan Khan. 0 7 0. SOLIDWORKS, August 6th, 2021 Gear Design. by MANISH CHAUHAN. 3 35 0. STEP / IGES, Rendering, August 6th, 2021 Bevel gear 16. by Design student. 2 19 0. STEP / IGES, Rendering, August 2nd, 2021 bevel gear. by Soumya Manna. 2 10 0. .

USB1

It is known to produce straight bevel gears, as well as skew bevel gears, face couplings and splined parts, by providing a pair of inclined rotary cutting tools whose rotating cutting blades effectively interlock to simultaneously cut the same tooth space on a workpiece. Examples of this type of machining can be seen, for example, in Pat. Nos. 2,586,451 to Wildhaber; 2,567,273 and ...

Bevel gear

Hypoid bevel gears are similar to spiral bevel, but the pitch surfaces are hyperbolic and not conical. The pinion can be offset above or below the gear center, thus allowing larger pinion diameter, longer life, and smoother mesh. If the beveled surface is made parallel with the axis of rotation, this configuration resembles a worm drive. Hypoid gears were widely used in automobile rear axles ...

Gear GrindinG

Norton offers a dressing solution for all spiral bevel gear grinding wheels: Contour controlled CNC dressing Very flexible One tool for several profiles Machine TO GrindinG Small lot size gear production can be time consuming and costly. Tooling cost and set up time may consume all hope for a profit. Norton has a full line of grinding wheels designed to grind the gear from solid. Machining to ...

Bevel Gear Grinding Model

Bevel Gear Grinding Model. Thanks to its outstanding grinding performance and universal design this CNCcontrolled bevel gear grinding machine from the G model series is an extremely economical concept for highprecision final machining of the curvedtoothed spiral bevel gears of any gearing system as well as facetype clutches.

klingelnberg warm grinding machines

Category bevel gear grinding machine Make KLINGELNBERG Type G27 Year of construction 2004 Wheel diameter max. 300 mm Wheel width approx. 60 mm Module max. 8 Module Klingelnberg HSS 350 Gear grinding machine Used machines. Klingelnberg HSS 350 Gear grinding machine 1 / 5. Manufacturer Klingelnberg Model HSS 350 Year 1974 Loion Spain Category Gear grinding .

bevel gear grinding model 5a872

Bevel Gear Grinding Model mill machine. Gear Grinding Machine For Spiral Bevel Gear Set Model. Gear grinding machine for spiral bevel gear set model 5A872 Manufacturer STANKO Condition perfect accesories can inspect under power workpiece diameter mm 800 module mm 16 number of teeth 4100 angle of spiral deg 060 tooth depth mm 33 width of ring or pinion gear mm 125.

Bevel gear transmission set2 gears 3D Printing Model

Bevel gear transmission set2 gears 3D printing model uploaded by tanerxun. A simple bevel gear transmission. There are two bevel : https...

Appliion Guide Gear Grinding

Gear Grinding Grinding Process Gear Box Types Workpieces Gear Modul Product Name Abrasive Type 3M Specifiion Preferred No. Of Strokes Performance Description Typical Machines Threaded Gear Grinding light vehicle gears, industrial gears, truck gears, aerospace gear components helical gear, spur gear, planet gear pinion shaft, pinion, 2 ...

Grinding

Grinding Phoenix 280G Faster Production of HighQuality for Automotive and Small Truck Sized Bevel Gears Phoenix 600G High Quality for Truck Sized Bevel Gears

Gleason Introduces New Phoenix II 275G Bevel Gear Grinding ...

Gleason's latest addition to the Phoenix® II product line is an advanced bevel gear grinding machine that utilizes the revolutionary monolithic column design. This concept reduces floor space and significantly reduces cycle times. The Phoenix II 275G accommodates gears with up to a 275mm pitch diameter, but with a machine footprint that measures just x meters (excluding the ...

Design and construction of Bevel gear

· The pitch surface of bevel gears is a cone. Fig : Some typical bevel gear The most common gearcutting processes include hobbing, broaching, milling, and grinding. Gears are commonly made from metal, plastic, and wood. Objectives: The main objectives of this project work are I. To solve a problem related to Bevel Gear II. To design that ...

Modeling of Vibration Condition in Flat Surface Grinding ...

Wang et al. proposed an analytical model for calculating the distribution of surface stress during grinding of bevel gear which was not developed in the previous models, taking into account the parameters of the process and two main factors to cause the surface residual stress, such as mechanical forces and grinding .

LowNoise, HighStrength, SpiralBevel Gears for ...

spiralbevel gear grinding technology (Scott, 1991). Advanced gear grinding was achieved through redesign of a current gear grinder and the addition of computer numerical control. The objective of this report is to describe the results of the experiments to evaluate advanced spiralbevel gear designs. The work was part of a joint Army

CAD Design data of our gearboxes

These models are divided according to gear type, gear series, size and transmission. If you are unable to find the model you are looking for, please contact us. 1.

Latest Posts

- الرمال السعري تأثير محطم

- 100 150 الفك محطم المصنعين

- مصنع خلط صغير مصر مستعمل للبيع

- مطحنة الكرة وإنتاج الزنك

- شراء آلة استخراج للحجر الجيري

- مكائن تعدين الذهب في السعودية

- خزان تحريك معدات التعدين الذهب ل zimbabwe

- كسارة الفك للبيع بي ام دبليو

- 5 مطحنة لالبنتونيت في مصر

- آلات تكسير الجير الإيطالي

- مصر مخروط مصر مصر في مصر

- سعر كسارة الفك الجبسية

- سحق الحصى في مصر

- سعر الحجر الجيري المسحوق للبيع في السلطة الفلسطينية

- أنواع آلات الطحن

- Ceramic Crushed Ceramic Crushed Manufacturers For Sale

- Digunakan Impactt Crusher Untuk Dijual

- Used Slag Grinder Machines Germany

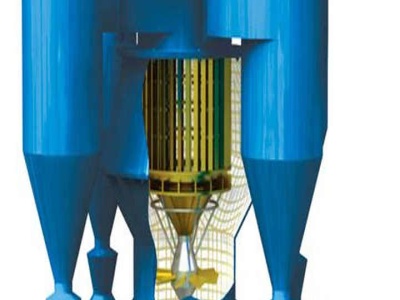

- Hydrocyclone Machineries China

- Stone Crushing Plant Keesara Crusher

- Bearings For Renk Ag Cement Ball Mill Gearbox

- Vsi Crusher Semi Automatic Grease Systm

- Gold Cyanide Processing Equipment

- Mining Scool Of Ghana

- Mini Quarry Machine Maker

- Mill Lead O Ide Production

- Small 50tpd Cement Plant Manufacturing Libya

- Blackrock Iron Ore Project Mining Canada

- Air Mikro Grinder Rpm

- New Type Cone Crusher For Yemen