Hardrock Mining Gold Processing

Blasting Drilling of Open Pit Mining

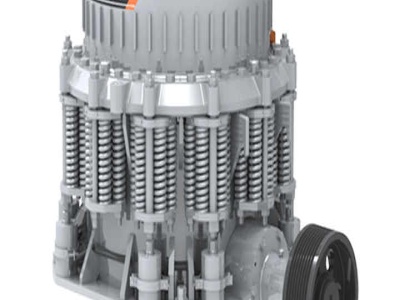

· Technical process,market; Pit design based on required flexibility. Number of extraction areas, mainly number of working benches; Adequate equipment – Drilling Rigs, Loader, Trucks, Curshers etc. More Articles. Hardrock Mining Drill Rigs Selection – Part Two; Hardrock Mining Drill Rigs Selection – Part One

Gold Processing Plant

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

Artisanal and SmallScale Gold Mining Without Mercury | US EPA

· This process is mostly used in large scale mining operations but has been increasingly adopted in small scale mining because of its high gold recovery rate and low cost. The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners, and high gold recoveries. First, concentration ...

Gold Mining Facts: Lesson for Kids |

Hard rock mining is the process of gathering rocks with gold veins and using large tools to remove the gold. This type of mining is most commonly used today. Once an area of rocks having large ...

Gold Mining Equipment for Sale

1. The Gold SONIC CONCENTRATOR or "Live Sluice", a two tray, heavy duty high oscillation gravity concentrator for hardrock and alluvial precious metals eaxtraction and concentration. These process from 50 to 150 Tons per hour and can be placed in series for higher capacity operations. 2. Portable HELICOID CONCENTRATORS called the Goldland "Blasters" which continuous feed and upgrade .

the process of hard rock gold mineral processing

Processing Hard Rock Gold Hard Rock Mining Gold and Silver Ore and processing it The main problem for individuals or small groups interested in hard rock gold deposits is the high capital costs both for the mining equipment to dig and remove the rock as well as the equipment to crush and process hard rock ore in order to extract the gold from its solid rock enclosure. Chat Online; How is .

Mining Technology in the Nineteenth Century | ONE

Underground mining took place in both hardrock and placer deposits and used excavation, support, hoisting, ventilation, and drainage technologies. Early miners dug shallow shafts to reach the ore body, which they then followed to create "rathole" or unplanned underground workings. Engineerdesigned or planned underground workings became more typical by the end of the nineteenth century.

TRIBES AND HARDROCK MINING

TRIBES AND HARDROCK MINING PROTECTING AMERICA'S WATERS FROM IRRESPONSIBLE MINING: Close the Clean Water Act's Mining Waste Loopholes American Indian tribes across the United States have been severely impacted by the tailings and other toxic waste dumped into America's waterways by the metals mining industry. Tribes own and manage nearly 95 million acres of land, .

Equinox Gold signs deal to increase stake in Hardrock Mine ...

· Equinox Gold has agreed to acquire an additional 10% stake in the Hardrock Mine Project in Canada from an affiliate of Orion Mine Finance Group, for at least 51m. The deal will increase the Canadian gold miner's stake in the Hardrock Mine Project to 60%. Loed in Ontario, Hardrock is a multimillionounce, fully permitted, construction ...

Dry Processing Plants For Alluvial And Hard Rock | DOVE

DOVE DESERTMINER ®, also known as Dry Processing plants, are mineral processing plants specifically designed by DOVE, with processing and recovery capabilities unmatched in the mining machinery industry.. DESERTMINER ® are configured for the simultaneous concentration, separation recovery of gold, platinum metals, base metals, ferrous metals from Alluvial deposits, and as well as .

Mining History and Geology of the California Gold Rush

The last hardrock mine shut down in 1965, and the last dredges ceased operation in 1968. In the early 1970's, the United State removed controls on the price of gold, and its value rose sharply. By 1980, the price per ounce reached more than 600 per ounce, and the attention of the mining industry once again turned to the Mother Lode. Surveys were undertaken during the 1970's and by the middle ...

Cyanide Use in Gold Mining

Mining lower grade ore requires the extraction and processing of much more ore to get the same amount of gold. Partially due to cyanide, modern mines are . much larger than before cyanide was used; create vast open pits; and; produce huge quantities of waste. More than 20 tons of mine waste are generated to produce enough gold for a typical ring. What are the dangers of using cyanide? Cyanide ...

Mining Techniques of the Sierra Nevada and Gold Country

Underground, Hardrock Mining. It was underground, hardrock mining operations that transformed California gold mining into a corporate activity. It was in the Northern Mines, clustered around Grass Valley, which dominated underground mining. In the beginning, the goldbearing quartz was wrenched from underground veins by backbreaking, dimly lit sweat and blood. However, imported miners from ...

Equinox Gold acquires Premier Gold Mines

· The Hardrock project, which has a proven and probable resource of million ounces of gold from million tonnes grading at grams per tonne, will be a joint venture with Orion Mine Finance. Orion will pay Centerra Gold, Premier's partner in the Hardrock project under the Greenstone Gold Mines Partnership (GGM), US225 million to acquire the remaining 50 per cent stake. The ...

Office of Wastewater Management

Hardrock mining is a largescale industrial activity that takes place in the natural environment, potentially disturbing large amounts of material and land area. Hardrock mining generates large volumes of mining waste because of the high wastetoproduct ratios associated with producing most ores. This page describes some of the potential environmental effects of hardrock mining. EPA ...

Gold Rock Mining Mills False

MBMMLLC is dedied to building costeffective gold ore milling and processing Smallscale hard rock miners do not have the luxury of a fully equipped and grinding circuit, with a gravity recovery system for the free milling values and ball mills or flotation plants to keep up with commerciallyviable mining operations. Gold Fever Giant Gold Machines Hard Rock Mining. Giant Gold Machines Hard ...

the process of hard rock gold mineral processing

Processing Hard Rock Gold Hard Rock Mining Gold and Silver Ore and processing it The main problem for individuals or small groups interested in hard rock gold deposits is the high capital costs both for the mining equipment to dig and remove the rock as well as the equipment to crush and process hard rock ore in order to extract the gold from its solid rock enclosure. Chat Online; How is gold ...

75TPH Hard Rock Gold Mining Plant in Sudan

· 75TPH Hard Rock Gold Mining Plant in Sudan. How processing plant configurated and what equipments were used? Read more... Gold Mining Equipment + [email protected] Menu. HOME; About Us . About Us. Our Partners; Certifie of Honor; The International Fairs; Close; SERVICE. Mineral Processing Experiment; Process Design; AfterSales Service; Close; Close; .

Office of Wastewater Management

Hardrock mining involves uncovering and extracting nonfuel metal and mineral deposits of solid ores or eroded deposits in streambeds. Eleven common minerals mined are copper, gold, iron ore, lead, molybdenum, phosphate rock, platinum, potash, silver, uranium, and zinc. Economic Value The combined value of the eleven metals and minerals listed above was billion, less than 1% of the ...

Manufacturers of gold mining prospecting equipment

Manufacturer of quality crushing and processing equipment for mostly hardrock mining appliions including flotation, Leaching and smelting. Equipment ranging in size from Lab scale to small production 5tph. Goldlands. 4550 Wynn Rd . Bellingham, WA 98226 USA. Ph: 360 201 2229. EMail: Goldlands Manufacturers of Production Gold Recovery Equipment including Continuous .

Latest Posts

- استخدام الفحم فى صناعة الاسمنت المصرى

- كسارات العنب

- كسارات الفحم الثانوية

- الفرن الدوار لخط التجفيف في الجزائر

- الصانع الكرة مطحنة eurpoe

- كسارات حجرية بلاستيكية صناعية

- سحق النباتات من الصين

- تأجير كسارة صغيرة متنقلة

- كسارات الحجر الجيري الفك الرمال مما يجعل الحجر المحجر

- مواد التعدين تحت الأرض

- الماركات كسارة الفك في مصر

- مصنع لتكسير الحجارة

- الكسارات خطة عمل

- فيرو التيتانيوم مصنع لتجهيز الرمل

- كسارة الحجارة للبيع في كينيا

- Industrial Grinder Forage

- Pro Le Sawmill Companies In Bc

- Mobile Stonecrusher Machine Boston

- Ika Mills Lab Mills Grinding Mill Crushing

- Pdf On Aluminium Can Crushing Machines

- Sc Series Stone Crusher

- Mini Grawal Stone Crasher Morocco

- Anglo Anglo Mulling New Coal Mine In South Africa

- Ball Mill Grinding And Particle Size Separation

- Machinery Manufacturer Mbs Rod Mill

- Crusher Sale Rubber

- Sales Performance Analysis Of Meghna Cement Mills Limited

- Productivity Of Jaw And Impact Crushers

- Small Scale Mining Equipment Laboratory Equipment Crushing Machine

- 1945 Mills Nickel Slot Machine