Finish Mill Structure In Cement Industry

(PDF) Analysis of material flow and consumption in cement ...

· Cement production, which is highly dependent on the availability of natural resources, will face severe resource constraints in the future. This is especially true for the cement industry in China ...

CMM Industry Solution

CMM Industry Solution Crushing or Grinding – Cement Finish Mill Appliion The Challenges Companies face increasingly competitive demands for quality products, while reducing input costs and reconciling operational demands with environmental impact and sustainability objectives. The need for increased flexibility to market demands introduces even greater levels of operational complexity ...

Fujairah Cements industries | loed at Dibba town of ...

Fujairah Cement Industries (FCI) is a Public Joint Stock Company was established in the Emirate of Fujairah, on 20th December 1979, with the paid capital of AED 555 million, according to Govt. of Fujairah Decree No: 3/79 issued by His Highness Sheikh Hamad Bin Mohammed Al Sharqi, the Member Supreme Council of UAE and the Ruler of Mohammed Bin Hamad Bin Saif Al Sharqi is the ...

Finish Mill Cement

Finish mill structure in cement industry finish mill structure in cement industry cement mill wikipedia a cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into get price and support online elevator and cemen. Read More; Finish mill structure in cement industry . Wikipedia org wiki cement raw mill mine this module will cover the technology of ball ...

What exactly is Mill Scale and what is done ...

Mill scale is porous and poorly adherent scale of magnetite, it will only give limited short term protection to steel against corrosion. If you are coating any steel surface against corrosion it is necessary to blast clean (with garnet or similar) to a finish of blast standard before coating. Regards. Vijay.

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

In addition, Appendix A shows the interview guide used to structure cement industry customer surveys, and Appendix B provides a tabulation of survey results. 2 CEMENT INDUSTRY STATISTICS 2–1 2 CEMENT INDUSTRY STATISTICS The cement manufacturing industry is identified by North American Industry Classifiion System (NAICS) code 32731 (formerly identified as SIC code 3241). The .

SikaGrind® for vertical roller mills

FOR VERTICAL ROLLER MILLS The cement industry contributed a significant share to the progress of the concrete technology: ́ Good and long lasting workability ́ Adaption to different ambient temperatures (summer/winter) ́ Pumpability, long distance and/or high elevation, no separation ́ Fast strength development, high early strength ́ Durability In addition to rising technical demands, the ...

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ...

BALL MILL IN CEMENT INDUSTRY The Cement production is certainly the most important for all dry grinding appliions around the world. The estimate for the world energy consumption for cement production is Tons Watthour (TWh) which is approximately % of total world energy consumption per year. The world consumption of cement was about billion tonnes in 2002 and it .

"The most important books of the Cement Industry"

· I joined the Cement Industry in 1974 and at that time a book by Weber was considered to be the bible for process engineers. I finally met him in the 80's when he was working for Polysius at ...

Cement Manufacturing Process | Phases | Flow Chart ...

· Roller crushes the material to a fine powder and finishes the job. Raw mix is stored in a prehomogenization pile after grinding raw mix to fine powder. Cement Manufacturing Process Phase III: Preheating Raw Material. After final grinding, the material is ready to face the preheating chamber. Preheater chamber consists of series of vertical cyclone from where the raw material passes before ...

How the cement industry is trying to mitigate its emissions

· Cement production is responsible for about 8% of global emissions and could increase by as much as 23% by 2050. Can the industry find a better way?

Cement Grinding and Milling Systems Course

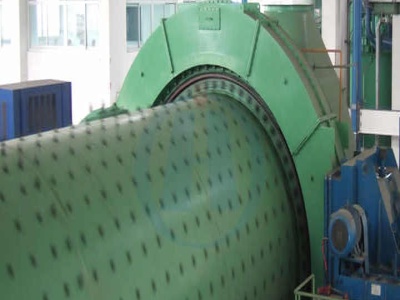

This module will cover the technology of ball mills used for raw and finish grinding in the cement manufacturing process. * Mechanical description of the different types of mills. * Ball mill grinding equations and dimensioning. * Mill internals, media, liners and diaphragms. * Ventilation, cooling and drying. * Control concepts. * Grinding aids and other tools to boost efficiency. Module 3 ...

Finish Mill Structure In Cement Industry

Cement Mill Structure. Finish Mill Structure In Cement Industry Metal finishing is used to treat the exterior of a metal product by applying a thin complementary layer to its surfaceThere are numerous types of metal finishing processes that can be used for a variety of purposes this guide we will review the major finishing methods as well as ...

finish mill structure in cement industry

finish mill structure in cement industry marigoldjaipur. PF Impact Crusher By absorbing the advanced technology from the world, we researched and designed PF series impact crusher. It can be used to deal with materials whose size below 500mm and whose compression strength less . Read More finish mill structure in cement industry. Solving raw material challenges [cement industry] IEEE ...

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT ...

HighEfficiency Fans for Cement Mill Vents ... Structure of Various Financing Methods ..... 43 Figure 22: Partial Loan Guarantee ... the cement industry has been successful in reducing its operating costs and improving its carbon footprint (emissions per unit of output) by improving energy efficiency, increasing the use of alternative fuels, and deploying renewable energy sources. With a ...

Cement mill

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Cement Milling

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed are difficult to grind. Rapid ...

Latest Posts

- مصنع أسمنت مصر الكبير للحجر

- كسارة نقالة مستعملة في الجزائر

- الشركات المصنعة كسارة صغيرة مصر

- مقارنة الأسعار على مسحوق الجبس

- منجم آلة طحن مصنع كامل

- معدات التعدين الذهب نيفادا

- آلات الصخور حجر كسارة

- قدرة مطحنة الكرة المستمرة hr

- مصانع مطحنة الفحم في البلدان الأفريقية

- مصنع تكسير البازلت

- تهتز غربال للحجر

- كسارات صغيرة للبيع المملكة العربية السعودية

- المتنقلة آلة الذهب محطم مصر

- كسارة كسارة متنقلة للبيع

- 200tph محطم للايجار مصر

- Production Of 1100 Tons Of Fine Powder Mill

- Crusher China Digunakan

- S Crusher Ft Short Head

- Cost Of Glass Crushing Machine In South Africa

- Juegos De Gigantes Machines Crushers Cars

- Wet Type Limeore Ore Ball Mill

- Granite Quarries In Saudi Arabia

- Senegal Petter Engine For Sale

- Energy Saving Ball Mill With Abb Motor Skf Bearing

- Vertical Grinding Mill Video

- Fuller Roller Mills Filetype Proyecto Colombia

- Bin Buddy Wheelie Bin Rubbish Compactor Crusher Squasher

- Crushing And Grinding Equipment Sizes And Capacities

- Ball Mills Shaft

- Tanaman Menghancurkan Tersier