Design Of A Small Ball Mill

Best Mini Milling Machine 2021 – The Practical Guides for ...

· The worktable size is pretty large and enough to handle both small and largescale jobs. And it is one of the reasons for this being the best mini mill for steel. Another plus point of Klutch Mini Milling Machine is, it features a 360degree swiveling head. .

Milling Cutters Tools

· Ball cutters, also known as ball mills, have a hemispherical cutting tip. The objective is to maintain a corner radius for perpendicular faces. Slab mill. Slab mills are not that common with modern machining centres. Rather, they are still used with manual milling machines to quickly machine large surfaces. That is also why slab milling is often called surface milling. The slab itself spins in ...

End Mills. The Essential Beginners Guide.

Ball Nose End Mills. Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece, meaning less work for you as the piece won't need to be finished any further. They are used for contour milling, shallow slotting, pocketing and contouring appliions.

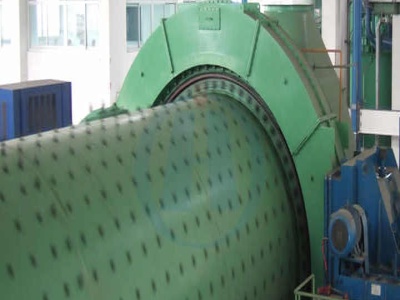

Ball Mill | Ball Mills | Wet Dry Grinding | DOVE

DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in 17 models, capacity range of ( TPH – 80 TPH). With over 50 years experience in Grinding Mill Machine fabriion, DOVE Ball Mills as critical component of DOVE Crushing plants are designed ...

Powder metallurgy – basics appliions

Rod mills: Horizontal rods are used instead of balls to grind. Granularity of the discharge material is 4010 mm. The mill speed varies from 12 to 30 rpm. Planetary mill: High energy mill widely used for producing metal, alloy, and composite powders. Fluid energy grinding or Jet milling: The basic principle of fluid energy mill is to induce

Used Ballmills For Sale

UNUSED FLSMIDTH 22' x 41'6" ( x ) Dual Pinion Regrind Ball Mill with 2 ABB 5,500 kW (7,375 HP) Drives for Total Power of 11,000 kW (14,750 HP) Manufacturer: FLSMIDTH. Inventory ID: 6CHM02. View Details.

The process design of gold leaching and carboninpulp ...

The objective during process design of these sections is thus to develop a design which provides maximum technical and economic efficiency and which is robust to potential changes in ore throughput, mineralogical characteristics and headgrade. Experience has shown that, particularly for longer life and highergrade projects typical of the South African underground gold mining industry, small ...

Design guide for CNC Milling

· Design guide for CNC Milling. July 22, 2016. Steven Weinberg. CNC milling is the most common fabriion method for professional prototyping, scaling well into the low to midvolume levels and sometimes higher. As with any manufacturing process, the more familiar the designer is the better and easier to produce the part will be.

Clay Processing

shredded in a disintegrator into small pieces to centimeters (cm) ( to 1 in.) in thickness. The shredded material then is either dried or ground in a hammer mill. Material exiting the hammer mill is mixed with water and bulk loaded as a slurry for shipping. Figure depicts the process flow for ball clay processing.

Milling Machine Terminology – Sherline Products

Mill Vise—A small vise that is clamped to the mill table and holds parts for milling. It is different from the more common drill press vise in that it tightens with a pulldown function that helps hold the part down as well as in to counter the forces of milling. It is also accurately machined so it can be aligned in the machine for accurate cuts.

Lab Stirred Ball Mill

Small Stirred Ball Mill. Recommended Products. Lab Stirred Ball Mill. Light Type Stirred Ball Mill. Production Type Stirred Ball Mill. Small Stirred Ball Mill. Please Feel free to give your inquiry in the form below. We will reply you in 24 hours. Your name : Your tel : * Your mail : Your company : Your country : * Inquiry : Products. High Frequency Vibrating Screen; Airflow Sieving Machine ...

PARTICLE SIZE REDUCTION TECHNIQUES

· BALL MILL Principle: The ball mill works on the impact between the rapidly moving ball and the powder material, both enclosed in a hollow cylinder. Thus, in the ball mill, impact or attrition or both are responsible for the size reduction. Fig: Ball mill 13 14. Working: The drug is filled into cylinder 60% of the volume. A fixed number of ball introduced and cylinder is close. Uses: Fine ...

Difference between C7 and C5 ballscrew | CNC Design Limited

Below we can see a picture of a test using a C7 ballscrew compared to a C5 ballscrew using really small wire of ( inch) and winding at a pitch of ( inch). So we should end up with a gap of between each winding. Remember to allow for difference in wire thickness also as it is never the same as the wire size due to ...

High Speed Spindle Design and Construction | Modern ...

· This paper will give a brief overview of the major components required to comprise a high speed milling spindle design. Emphasis will be on commercially available components, that are available at reasonable cost, and most commonly used today on existing machine tools. Future trends will also be mentioned. In addition to the high speed spindle system design, maintenance and reliability .

The Working Principle of Hammer Mills (Stepbystep Guide)

The complexity of the control box will depend on the unique design of the milling machine. A hammer mill control box . For instance, you may control the feeding system or motor speed. Some pharmaceutical milling machines come with a display panel where users can monitor all processes. · Crushing knives or hammers. These are the fundamental tools that crush or grind materials. They rotate at a ...

The operating principle of the ball mill

· In filling mill by grinding balls on 40 – 50% and nonsmooth liner, the outer layers slip is virtually absent, but the sliding of the inner layers one on another observed in various modes of operation mill. In a monolayer filling mill by grinding media, they rotate around their axis parallel to the drum axis of rotation. Grinding media are not subjected to a circular motion by a smooth ...

Milling cutter

Milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations (and occasionally in other machine tools).They remove material by their movement within the machine (, a ball nose mill) or directly from the cutter's shape (, a .

Ball Mill Parameter Selection Calculation

· In the ball mill, the size and proportion of steel balls have a great influence on the productivity and working efficiency of the mill. For coarse and hard materials, larger steel balls should be selected, for fine and brittle materials, with smaller diameter steel balls, the impact times of steel balls in the mill increase with the decrease of ball diameter, and the grinding between balls ...

Introduction to Milling Tools and Their Appliion

Ball end mills produce a radius at the bottom of pockets and slots. Ball end mills are used for contour milling, shallow slotting, contour milling and pocketing appliions. Flutes Spiralshaped cutting edges are cut into the side of the end mill to provide a path for chips to escape when an end mill is down in a slot or a pocket. The most common options are 2, 3, or 4 flutes. The more flutes ...

Ball End Mills | Regal Cutting Tools

A square end mill with a radius ground on the corner can provide a small radius at the juncture if reduction of stress is the desired objective. The design of a two flute ball end mill allows for plenty of chip evacuation making them most effective in contouring deep pockets in molds and dies. Four or more fluted ball nose end mills have less chip evacuation due to their design but with ...

Hammermill

The screenless hammer mill uses air flow to separate small particles from larger ones. It is designed to be more reliable, and is also claimed to be much cheaper and more energy efficient than regular hammermills. The design structure of the hammermill is always determined by the end use.

Ultrasmall Micro End Mills | Request PDF

Ultrasmall diameter cemented carbide ball end mills have been developed. Tools having a radius of ball nose of 10 μm have been manufactured by electrical discharge machining (EDM), because ...

Free CAD Designs, Files 3D Models | The GrabCAD ...

The ComputerAided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by thirdparty users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or realworld item, product, or good it may purport to portray. The GrabCAD Library offers millions of free CAD designs, CAD ...

Ball milling: a green technology for the preparation and ...

Ball milling: a green technology for the preparation and functionalisation of nanocellulose derivatives. Carmen C. Piras a, Susana FernándezPrieto b and Wim M. De Borggraeve * a a Molecular Design and Synthesis, Department of Chemistry, KU Leuven – University of Leuven, Celestijnenlaan 200F, Box 2404, B3001 Leuven, Belgium.

Latest Posts

- سعر خطة غسيل الرمال للبيع

- آلة كسارة الحجر الصغيرة في اليمن

- تلال كسارات الحجر

- كسارات الحجر ومنفاخه

- مكثف خام النحاس المحمول الصغيرة

- خطة عمل للتعدين الجير شركة

- كسارة تصادمية وحدة تتبع المحمول

- سحق الرخام في المجاميع

- تجهيز كسارة الرخام الجرانيت الحجر

- مطحنة تكسير الأسطوانة السعودية

- غسالات رمل في مصر

- تستخدم كسارة الفك 500 الهيدروكربونات النفطية

- كسارة محاجر في الجزائر

- 25 العارية مخروط محطم للبيع

- عملية طحن طحن الأسمنت

- Mining Equipment Hydraulic Rock Crushing

- Mineral Grinder Need

- Mill Foundationdesign Ball Mill

- Grinding Ball Manufacturer Manufacturing Of Ball

- Double Roller Crusher Manufacturers

- United Arab Emi Machine Molybdenum Solution

- Impact Crushers Bullhead City Az

- Jaw Crusher Price In Lesotho In Bellary Karnataka Lesotho

- List Of Registered Operate In Cement Factory

- Laboratory Ball Mills For Sale

- Impact Crusher Mobile Crushing Station Impact Crushers Mobile Crushing

- Why Magnetite Attracted By Magnet

- Izin Usaha Pertambangan Batubara Pt Arka Mining

- Heparin Sodium Hospira

- Vertical Bead Sand Mill Price