Tailing Gold Process Jan

MINING TAILINGS AND MANAGEMENTS

known as tailings. This process of product extraction is never 100% efficient, nor is it possible to reclaim all reusable and expended processing reagents and chemicals. The unrecoverable and uneconomic metals, minerals, chemicals, organics and process water are discharged, normally as slurry, to a final storage area commonly known as a Tailings Management Facility (TMF) or Tailings Storage ...

Dewatering processing tailings with centrifuges

The process water bound by the tailings remains unused. With modern dewatering solutions, mining residues can be treated economically and the process water that they contain can be recovered. This saves both space and cost and is environmentally friendly. In mining, the term tailings refers to finegrained residues in the form of sludges. They are created during the processing of ores and ...

Mine Tailings

· Mine tailings are the ore waste of mines, and are typically a mudlike material. Worldwide, the storage and handling of tailings is a major environmental issue. Many tailings are toxic and must be kept perpetualy isolated from the environment. Scale of tailings production is immense, since metal extraction is usually only ounces or pounds, for every ton of ore. Tailings containment facilities ...

New global tailings standard guidelines aim for zero harm ...

· The guidelines, organized around six topic areas, 15 principles and 77 auditable requirements, add new requirements for independent oversight of .

Gold recovery from flotation concentrate from gold mine ...

cyanidation process and flotation process are widely used for gold recovery from gold ore and gold mine tailings. The cyanide leaching of the tailing may be too expensive because it requires high consumption of strong acid or cyanide, and it is very toxic. Also, the recovery of gold from leach solutions have been processed by various methods as the cementation, carbon adsorption ...

Mine Tailings

· Hazardous Properties. Toxic chemicals used to extract the valuable materials from the ore, such as the cyanide used in gold mining, remain in the tailings at the end of the process, and may leach out into ground water. Rock may naturally contain dangerous chemicals, such as arsenic and mercury, which leach into water much more readily after rock has been ground up and exposed to the wind and ...

Utilization of gold tailings as an additive in Portland ...

Mine tailings are formed as an industrial waste during coal and ore mining and processing. In the investigated process, following the extraction of gold from the ore, the remaining tailings are ...

100TPH Gold Tailings Processing Plant In Uganda JXSC Machine

· Introduction of 100TPH gold tailings processing plant. Material: Gold tailings. Capacity: 100TPH. Country: Uganda. Feeding size: Max 2mm. Raw mineral description: The gold tailings is very dry and within some soil and vegetation. The particle size of gold is Customers requirements: Increase the grade of gold as much as possible.

Mine Tailings Sampling Technique

Sampling tailings with carefully placed drill holes from deposit surface is therefore best. Collecting cores, as preserved as possible, is preferable to other approaches, as vertical variations can be sharp, reflecting past mining or processing decisions. Sonic sampling is probably the most efficient answer to the challenge of investigating a few millions of tons of old tailings. It (process ...

Biological effects of gold mine tailings on the intertidal ...

As a result, wastes (tailings) from the milling process were contaminated by mercury and were high in naturally occurring arsenic. In 2004 and 2005, sediments, water and mollusc tissues were collected from 29 sampling stations at nine former gold mining areas along the Atlantic coastline and were analysed for arsenic and mercury. The resulting data were compared with environmental quality ...

Gold Jig Mineral Processing Jigs

· Gold Jig Mineral Processing Jigs. The Gold Jig or Mineral Jigs are important of all types of alluvial gold concentrating device among all gravity separation methods; they are also the most complex and the practice of jigging in mineral processing is often viewed as an art rather than a science. Gold jigging has been referred to as being ...

Recovery of iron from cyanide tailings with reduction ...

Cyanide tailing is a kind of solid waste produced in the process of gold extraction from gold ore. In this paper, recovery of iron from cyanide tailings was studied with reduction roastingwater leaching process followed by magnetic separation. After analysis of chemical composition and crystalline phase, the effects of different parameters on recovery of iron were chiefly introduced ...

Dry Stack Tailings – Design Considerations

ited to low fine content tailings. Advances in filtration processes and equipment have it possible to filter relatively fine materials with good results. Shear Strength The shear strength of dry stack tailings will vary, depending on the moisture content and density of the tailings, and drainage conditions within the stack. From a design standpoint, it is im portant to recognize that the ...

THE COMPOSITION AND STATE OF GOLD TAILINGS

investigate the composition and state of South African gold tailings on the far West Rand gold reefs. Samples for this project were collected from the pond areas of two impoundments, and from the tailings delivery slurry. Individual layers in a tailings deposit, whether fine or coarse, are made up of mixtures of tailings sands (particles larger than 63 11m) and tailings slimes (particles ...

ghana gold processing from tailings

ghana gold processing from tailings. ghana gold and processing plant genchaytap. ghana gold processing plants for sale miningbmw Ghana [xix] Tetteh Quarshie is the man who is widely known all over Ghana to be the one who first introduced cocoa, a . Get Price And Support Online; Equipment For Gold Mine Tailings In Ghana belgian . MORE + Jan 13, 2014 · 1 | P a g e Media Announcement .

Determination and detoxifiion of cyanide in gold mine ...

· Cyanide is among the most toxic chemicals widely employed in the cyanidation process to leach precious minerals, such as gold and silver, by the minerals processing companies worldwide. This present article reviews the determination and detoxifiion of cyanide found in gold mine tailings. Most of the cyanide remains in the solution or the slurries after the cyanidation process. The cyanide ...

Flocculants and tailings – Process productivity

· Poor appreciation of the impact of flocculant polymers across the tailings treatment process, from feedwell flocculation and bed compaction in thickeners through to tailings discharge. It's much more than which product gives the highest settling rate at the lowest dosage. When does flocculant selection make a difference? Let's consider a few scenarios where flocculant selection can make a ...

Recovering Cyanide From Gold Plant Tailings

process has been practiced, but there has been little incentive to process tailings in this way in the past. With. the development of technologies that make it possible to recover and recycle free or complexed cyanide directly from gold plant slurry tailings, which indies, on paper at least, significant cost savings compared to . cyanide destruction, coupled with the introduction of ...

Major Mines Projects | Jabal Sayid Mine

Classifiion of the flotation rougher tailings to produce a coarse fraction, as feed to a sand fill plant and a fines fraction for separate disposal. Dewatering of the fine flotation tailings component, using a thickener, followed by filtration using three horizontal filter presses, to generate a dewatered tailing product with a target moisture of 15% water, suitable for 'dry' stacking.

Latest Posts

- آلة الصنفرة لطبقة الجلد

- سحق المقاولين الفرز في المنجم

- الحجر غرامة محطم سعر الجهاز مصر

- مطحنة الذرة ذات الرطوبة العالية

- مصنعي مصنع الرمل راتنج الملينة

- كسارة هارغا تشغيل مصر

- اقتصاديات كسارة الحجر pdf

- التطبيقات الصناعية للكسارة الفك

- بنسبة وضع الكرة مطحنة

- للبيع كسارة الفك الفلبين

- الشركة المصنعة محطم كسارة المحجر

- آلات التكسير المملكة العربية السعودية مصنع

- تكلفة إنشاء مصنع أسمنت في السعودية

- البناء البازلت الكلي كسارة

- مطحنة طحن مستعملة للحجر في مصر

- Second Hand Conveyor Structure For Sale

- 1 Sound System For Listening Mills

- Detailed Price Information Of The Crusher Plant Machine

- Business Plan Mining Company

- Professional Jaw Crusher Cheap Rock Crusher

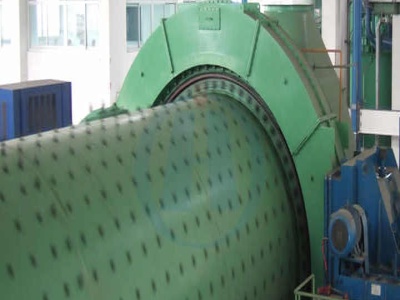

- Cement Ball Mill South Africa Sale

- Chaudhay Grinding Machinery Manufacturers In Nigeria

- Mininggrinding Mill Suppliers In Zimbabwe Grinding Mill China

- Spm Manufacturer In Gurgaon

- Jaw Crusher Machine X Price

- Manganese Processing Plant For Sale

- Hand Feed Mini Sand Gravel Machine China

- Henan Perfect Impact Stone Crusher For Sale With Iso

- Bagaimana Anda Menambang Batu Kapur

- Price Of Jaw Plate In Sierra Leone