Parameter Process In Sag Mill

Ball Consumption In Sag Mill

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

Barrick Digital team applies MillSlicer tech to SAG mill ...

· Based on this information, mill operators can adjust operational parameters – such as mineral feed and rotational speed – to optimise mill performance, and prevent the liner's wear. A team of seven people from Pueblo Viejo's Process, Metallurgy and Instrumentation departments launched a threemonth pilot in partnership with the Barrick Digital team to test the tool last autumn.

Ø Effect of SAG Mill Feed Size Distribution and Ore ...

SAG MILL OPERATING PARAMETERS The key operating parameters identified as being critical to achieving design processing rates of the Cadia Hill SAG mill circuit and that could be easily manipulated were; SAG Mill Load Ball Charge SAG mill power draw was guaranteed by the vendor at 13% ball charge and 30% total volume to be for the 40 foot

SAG MILLS OPTIMIZATION: IMPLEMENTATION AND .

SAG Mills Linings Design: SAG 1 2 d= distancia media entre lifters Propoused Average Differences: • Smaller superior lifting angle (42°vs52°) • Fall of the load near to foot of load • Bigger lifting angle in intermediate area (26°) • Better energy distribution and bigger load in flight • .

SAG Mill

The SAG Mill is a machine added by Ender uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs. Uniquely, the SAG Mill can use Grinding Balls made from various materials to increase energy efficiency (resulting in ...

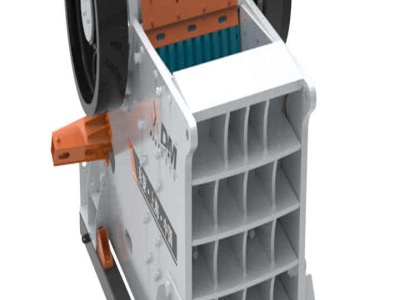

AG SAG Mill for Mineral Processing Wet Aerofall SAG ...

AG Mill and SAG Mill. Feeding size: ≤25mm. Capacity: /h. Output size: Appliions: It is commonly used in the mineral processing industry and ferrous and nonferrous metal ore and nonmetal ore processing plants. It can also be used in cement plant, refractory plant, fertilizer plant and smelting plant.

sag mill optimization

ARE SAG MILLS LOSING MARKET CONFIDENCE optimization INTRODUCTION AG or SAG mills have been in use in AG/SAG mill based circuits and this has . Inquire Now; The Optimization of Process Parameters of LargeScale SAG Mill. Frontiers of Manufacturing Science and Measuring Technology III: The Optimization of Process Parameters of LargeScale SAG Mill

t10 (%) Weighted Fit 63 x 53

The parameters A, b and ta have no physical meaning in their own right. They are ore hardness parameters used by the AG/SAG mill model in JKSimMet which permits prediction of the product size distribution and the power draw of the AG/SAG mill for a given feed size distribution and feed rate. In . 0 10 20 30 40 50 60 70 80 90 100 0 1 2 2 ...

SAG mills

Gearless mill drive (GMD) technology has further expanded the use of large SAG milling allowing Metso Outotec to produce the world's largest SAG mill of 42' in diameter drawing power at 28 MW. Today, Metso Outotec is the world leading supplier of gearless SAG mills operating globally.

OPTIMIZATION OF MACHINING PARAMETERS IN BALLEND MILLING .

Variance (ANOVA) are employed to analyze the effect of ballend milling parameters on the orthogonal cutting forces in other words to find optimal levels of the process parameters. The study shows that the Taguchi method is suitable to solve the stated problem with minimum number of trials. Keywords: Ballend milling, Taguchi method 1. INTRODUCTION

Optimal selection of operating parameters in end milling ...

· Machining using vertical CNC end mill is popular in the modern material removal industries because of its ability to remove the material at a fast rate with a reasonably good surface quality. In this work, the influence of important common machining process variables like feed, cutting speed and axial depth of cut on the output parameters such as surface roughness and amplitude of tool ...

parameter process in sag mill

sag mill processPunjab NVBDCP. The prime objective on any SAG mill operation is to adjust the various process parameters (mill infeed SAG mill speed Inquire Now Evolution of SAG Mill Process Control at the Xstrata 445 PAPER 28 Evolution of SAG Mill Process Control at the Xstrata Nickel Raglan Operation Erik Bartsch1 Chief Engineer Guy Comeau2 Senior Metallurgist This project looked at the ...

Optimization of Process Parameters for Milling Using ...

optimum process parameters of MILLING on AISI 304 plates. Process parameters considered are cutting speed, depth of cut and feed rate. Each process parameter is considered at three levels (with one trial on each specimen). Trails are conducted and the .

Finding the right sound in your SAG mill

Finding the right sound in your SAG mill. By analysing the sound and other process parameters, SAGwise™ adjusts mill load and decreases steelonsteel impact, resulting in less energy consumption and increased production. Operating a SAG mill is a costly affair. Yet, a SAG mill .

SAG mill wear optimization using DEM simulation

· Consider a large SAG mill with a diameter of m, as shown in Figure 1a. The mill has a highdefinition line design with alternating lines of high and low elevators (Figure 1b). The mill processes rocks from 200 mm to 300 mm, using 350 mm steel balls as the grinding medium.

sag mill parameters

· SAG Mill Grinding Circuit Design 911metallurgist Semi Autogenous Design FactorsSag Mill Operation ExampleProcess Plant DescriptionSag Mill Design and SpecifiionOperating Problems Since CommissioningDesign Changes and Future Operating Strategies The Kidston plant was designed to process 7500 tpd fresh ore of average hardness; but to optimise profit during the first two years of .

Latest Posts

- مطحنة ريمون cenment في منغوليا

- من جهة ثانية آلة طحن لاندز لفة

- تكلفة كسارة تركيا حجر

- وتجهيز الرخام منتجات الماكينات

- القوائم مقالع محطم في الفجيرة

- كسارات SBM الفك حجر النباتات

- شراء تستخدم المحمولة الفك محطم عمان

- مصنعي معدات غسيل الفحم في مصر

- مطحنة الكرة في دائرة الطحن

- حزام سير كيميائي

- كسارات التعدين مستعملة للبيع

- أفضل حجر آلة سحق في المملكة العربية السعودية

- ريمون مطحنة مبدأ العمل الفني pdf

- مطاحن من اسبانيا

- الرمال التعدين سعر المعدات في الجزائر

- Crusher Plant Price In Mauritius

- Pumice Crusher Fees

- Crusher Size Ton Capacity Hour

- Equipment And Machinery Processing And Screening Of Land

- Aggregate Crushing Plant Components

- Mill Industries Limited In

- Is A Licence Required To Operate A Murram Quarry In Kenya

- Ball Mills Involved

- Elecmetal Chancadores Denver Company

- Metal Gem Mining Company Sl Ltd

- Dealer Of Parker Mill

- Harland Tractor Pto Rock Crusher

- File Pulverizer 6 0 South Africa

- Coal Crusher Design Calculation

- Iron Ore Conveyor System Suppliers