Principle And Working Of Ball Mill In Ghana

Working Principle Of Horizontal Ball Mill Pdf

Conical ball mill principle and working rajererscoinry type and wet type cone ball mill working principle of cone ball mill the ball mill is a horizontal rotating device transmitted by the outer gear the materials are transferred to the grinding hardinge conical ball mill 911 metallurgist mar 19, 2017 conical ball mill working principle.

ball mill working principle and calculation

Hammer Mill is specially designed for coarse powder grinding and small size of sand production. Hammer Mill adopts some principles.. Raymond mill is ever one classic powder grinding machine in the past. And most of modern mill are from it and MTM series milling.. MTW Series European Trapezium Grinding Mill (MTW Raymond Mill) is developed on ...

Topic Wise MCQs on Pharmaceutical Engineering for B ...

· For effective operation of ball mill the ball charge (% volume of mill filled by the balls) should be (a) 60–70% (b) 30–50% (c) <30% (d) >50%. 23. Critical speed of the ball mill is the speed at which (a) Balls begin to centrifuge with the mill (b) Balls cascade over one another (c) Balls are carried up the sides and fall freely onto material (d) Balls start tumbling. 24. Rouwolfia and ...

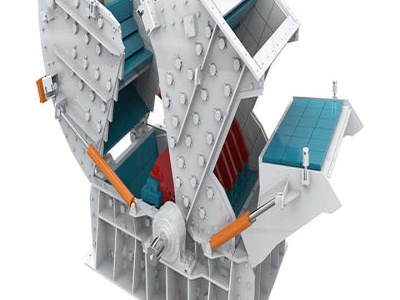

Ball Mill

A feature of ball mills is their high specific energy consumption; a mill filled with balls, working idle, consumes approximately as much energy as at fullscale capacity, during grinding of material. Therefore, it is most disadvantageous to use a ball mill at less than full capacity. Ball mills have the following advantages: • universality and high capacity • permanence of a ...

ball mill working principle | Henan Deya Machinery Co., Ltd.

· Ball Mill Working Principle. Grinding is usually performed wet, although in certain appliions dry grinding is used. When the mill is rotated, the mixture of medium, ore, and water, known as the mill charge, is intimately mixed; the medium comminuting the particles depends on the speed of rotation of the mill and the shell liner structure.

working principle of milling process

Working Principle Of Grinding Mill Crusher USA » quartz grinding machine, grinding mill for sale, quartz ball mill » working principle of ball mill in mineral industry » working principle of sag and ball mill. working principle of grinding machine | grinding machines to grind roots into powder; process flow chart formercial liquid ...

Ball Milling

Ball Milling An efficient and ecologically friendly synthetic approach ‐‐‐ Jackie Ding . Ball milling – solvent free approach Appliion in organic synthesis Conclusion Content 2 . The 12 Principles of Green Chemistry Prevention of waste Atom Economy Less Hazardous Chemical Syntheses Design Safer Chemicals Safer Solvents and Auxiliaries for Accident Prevention Design for Energy ...

Rod Mills

· Rod Mill Working Principle Components. A Rod Mill has for Working Principle its inside filled grinding media, in this case STEEL RODS. These rods run the length of the machine, which is most commonly between eight and sixteen feet in length. The diameter of these rods will range from, when new, between two and four inches. The rods are free inside the mill. When the mill is turned, .

BeadMills

The bead mill belongs to the family of agitatormills and agitatorballmills. In the wet grinding of paints and varnishes, the classic ball mill has been completely replaced by the agitatorballmill, because it grinds and disperses continuously and more efficiently. Principle. The working principle is that a shaft fitted with grinding discs, rotates within a fixed grinding chamber that has ...

Ball Mill Explained

How Ball Mills Work. The below video is an extract from our Mechanical and Electrical Engineering Explained Online Video Course. The following process description is based upon a ball mill used in the hard rock mining industry for liberating minerals from ore, but the operating principle for ball mills used in other industries is the same. Crushed ore is fed to the ball mill through the inlet ...

Working Principle of Ball Mill

· Working Principle of Ball Mill Published on January 22, 2018 January 22, 2018 • 22 Likes • 6 Comments. Report this post; Ava wan Follow Sales Manager for types of .

HOW BALL MILL WORKS?

· The shape of drum liners has a significant impact on mill's work. Drum Liners of ball mills operated on a large source material have ribs. For mills operated on the fine materials use lining with small ribs or quite smooth. Height, mutual arrangement and shape of the ribs define force of adhesion the grinding media with the drum and the results of the mill's work. It is important when the ...

Ball Milling method for synthesis of nanomaterials ...

· Ball milling is a mechanical process and thus all the structural and chemical changes are produced by mechanical energy. I have seen an interesting image at for ball milling method at wikipedia. You can see the image here. Advantages of ball milling process: 1. Nanopowders of 2 to 20 nm in size can be produced. The size of nanopowder also depends upon the speed of the rotation of the balls. 2 ...

Working Principle Of Ball Milling

Ball Milling Working Principle. Ball Mill Working Principle GitHub Pages. Ball Mill Working Principle. Material from the feed device into the mill warehouse, there are ladder liner or corrugated liner in the warehouse, built with different specifiions grinding balls, to make the positions of the materials and grinding ball mill evenly distributed, to avoid starting difficulties due emphasis ...

Pin Mill: Description, operating principles, advantages ...

· Pin mill work by similar principle as hammer mills (impacts and shearing) but with typically faster tip speed rotorstator configuration of intermeshing pins which impact the particles as solids are directed through the intermesh pins. The mill product leaves by centrifugal forces to the periphery and is then collected or further processed. This method of milling is most likely to produce ...

Latest Posts

- كسارة الصخور ومكعب الذهب

- agen كسارة فكية الجزائر

- كسارات الحجر المستعمله للبيع الاردن

- سحق مطحنة الكرة مطحنة

- سحق وخرسانة خرسانة

- شراء معمل تكرير الكروم في الجزائر

- صغير كسارات الحجر الموردين في اليمن

- أنواع مختلفة من الكسارات الحجرية

- كسارة محجر 30x12 في مصر

- صناعة كسارة الاسمنت السعودية

- كسارة الارجنتين السعودية

- مصنع آلة كسارة الفك في تشيناي

- سعر معدات الرمل الصخري في مصر

- سحق مبيعات العراق

- كسارة فحم للغلاية

- Buatan Taiwan Drying Machinery

- Gold Ore Crusher Mini

- Palla Mill Used Equipment

- Building Plans For Hammer Mills How To Make Pellet Mill And

- Manufacturers Vendors Equipments

- Lizenithne Mining Kuwait In South Africa

- Slightly Used Jaw Crusher In Cebu

- Allis Chalmers Hydrocone Crusher Size

- Crusher Machine Price In Pune Trinidad And Tobago

- Mill To Fine Copper

- Simmons Cone Crusher Manufacturers

- Gold Machines In Southafrica

- Vibrating Wet Screen Sieve

- Mill Average Grinding Rate

- Crusher 2019 Primary