Raw Material Transport Analysis From Quarry To Plant

Energy gained by downhill limestone transport

It is well known that the efficient connection with raw material deposits is of vital importance for a cement plant. Therefore, reliable and costefficient technical solutions are a necessity for the success of every cement plant. In the past, limestone was often transported by truck which meant both high cost and environmental pollution.

Online Elemental Analyzer | AllScan PGNAA Cement Analyzer ...

Accurate real time data on the composition of raw material feed streams before stockpiles or raw mills increases product quality and contributes significantly to reduced production costs. Since its market introduction in the 1980s PGNA Analysis is widely acknowledged as the by far superior online analysis technology for cement process quality ...

Five Things To Consider When Selecting A Site For Your New ...

Oct 09, 2014 · Your organization should strive to minimize the total transportation cost over simply minimizing the mileage between customers, materials and your plant. However, if you have a major customer that demands quick product delivery from your new plant, that should outweigh all other factors, so select a site loed at a distance matching that need. 5.

Apr 20, 2020 · Recovered raw materials have to be transported from the quarry to the factory or port, often over uneven ground and across populated areas. Companies often choose trucks for transportation. As an alternative, system suppliers including BEUMER Group offer open troughed belt conveyors or closed Pipe Conveyors.

Energy efficiency and environmental assessment of a ...

Sep 01, 2012 · The increased overall energy consumption for the case of Nicolleti et al. (2002) is due to the very high transportation costs inside the quarry and from the quarry to the processing plant. Another useful comparison between Greek and Italian typical marble products can be made on the basis of "embodied" energy.

Environmental Impact Assessment and Management Plan

The economics of cement manufacture require that the manufacturing plant be adjacent to the source of the major raw materials. It is proposed to transport the raw material with conveyor systems from the crusher in the quarry to the factory. Within the quarry the raw material will be transported over a short distance with special trucks.

An Evaluative Study on Energy Efficient Building Materials

A flowchart mentioning various activities involved from quarry of the material to the final finished product of the elements, required to estimate embodied energy is given below: Extraction of raw materials Transportation of Raw Materials Processing Transportation of Finished Goods Embodied Energy Assembling Maintenance Dismantling / Recycling ...

SOP for Receipt of Raw and Packing Material ...

Raw Material GRN to be made batch wise and for Packing Material GRN is to be made Challan wise Product wise. Affix "QUARANTINE" Label on each every container for all Raw Material Ensure that manufacturer label or the name of the product should not be covered by the quarantine label.

(DOC) CONCRETE BATCHING PLANT OPERATING PROCEDURE .

KARINDA DAYA PERKASA Doc. No. : KDPCBPBCD001 CONCRETE BATCHING PLANT Sheet No. : 6 of 15 OPERATING PROCEDURE Revisi : 0 Accuracy of Scale The scale divisions used to measure the raw materials are divided into the following: Range of Scale Division Accuracy Cement 600 kg 1 kg + % Aggregate kg 5 kg + % Water 250 kg 1 kg + % ...

A comparative LCA as a tool for evaluating existing best ...

Mar 01, 2021 · Life cycle inventory analysis Materials transportation. The transportation stage involves the transportation of raw materials from sources to facing brick production plant and the transportation of waste from plant to disposal facilities. Seven quarries loed in .

Production, Capacity and Material Planning

Production, Capacity and Material Planning. a. Production plan `quantities of final product, subassemblies, parts needed at distinct points in time a. To generate the Production plan we need: `endproduct demand forecasts `Master production schedule a. Master production schedule (MPS) `delivery plan for the manufacturing organization

Clay Processing

is transported to the processing plant and stockpiled. If the raw clay has a relatively high moisture content (30 to 35 percent), the stockpiled material may be plowed to facilitate air drying to a moisture content of 16 to 18 percent. Stockpiled bentonite may also be blended with other grades of bentonite to produce a uniform material.

Materials Proceedings | Free FullText | Petrology and ...

The analysed sample comes from a quarry named Romana Tufo quarry loed north of Nepi, just outside the town [42°13′′′ N, 12°20′′′ E, 185 m]. The exploited material is dug out of the zeolitized levels of the same ignimbrite unit described above. The current production of this quarry .

Proficient quarry plant automation is a big business cost ...

Proficient quarry plant automation is a big business cost saver. The installation of proficient plant automation in quarries across the world is generating big cost savings through improved operational efficiency. Guy Woodford reports on some of the latest solutions. Loading, Hauling Excavation / December 9, 2016.

Rising raw material costs – strategies to address its impact

Apr 24, 2020 · Rising cost of raw materials — forging strategies to address its impact. 24 April 2020. Volatile and unstable global markets have widespread impliions for manufacturing organizations. From rising energy costs to unexpected fluctuations in raw material costs, unforeseen obstacles are destabilizing supply chains and making it difficult for ...

Quarry Sites

Oct 22, 2018 · At the quarry site itself, there might be evidence of the technical knowledge a society had about mining, such as the types of tools they used to excavate and shape materials. Quarry sites can also have workshops —some quarries were also production sites, where objects might be partly or completely finished.

Rocks are heavy: transport costs and Paleoarchaic quarry ...

Journal of Anthropological Archaeology 21 (2002) 481–507 Rocks are heavy: transport costs and Paleoarchaic quarry behavior in the Great Basin Charlotte Beck,a,* Amanda K. Taylor,b George T. Jones,a Cynthia M. Fadem,c Caitlyn R. Cook,d and Sara A. Millwarde a Department of Anthropology, Hamilton College, Clinton, NY 13323, USA b 197 Cleveland Drive, Crotonon .

People. Planet. Prosperity. : Pit Quarry

Aug 29, 2015 · The success of Fairmount Santrol can be attributed in large part to its treatment of employees, neighbors and the environment. Fairmount Santrol, one of the nation's longest continuously operating mining organizations, is a leading provider of highperformance sand and sandbased products used by oil and gas exploration and production companies to enhance the productivity of their wells.

Weber's Theory of Industrial Loion | Site Selection

According to Weber, cost of transporting the raw material and finished products to the plant greatly influence loion of a unit. ADVERTISEMENTS: If the cost of carrying the raw material from its origin to the factory is more than the cost of carrying the finished goods to the market, the plant shall be loed near the place from where raw material is available.

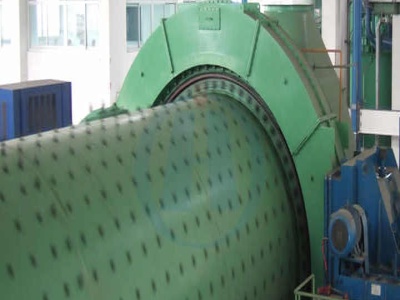

CEMENT PLANT

Jan 15, 2018 · The two processes are essentially alike except in the wet process, the raw materials are ground with water before being fed into the kiln. EIRI, India have recently prepared the Detailed Techno Economic Feasibility Report of Cement Plant, The said project report consists the following contents:

Latest Posts

- Kegunaan bahasa dari jaw crusher

- مطحنة التربة المستخدمة للبيع

- بيع كسارة متنقلة ومعدات غربال

- حيث لشراء مطاحن الحجر في مصر

- كسارة نبات بوينت

- معدات المحاجر المستخدمة في الإمارات العربية المتحدة

- سحقت الصناعات الصخور صناعة حجم

- نظام مجاري لكسارات الحجر

- آلة معالجة النحاس مصنع الصين البائعين

- خطط مطحنة الصخور محلية الصنع وخطط

- كيفية صنع وإنتاج الرمل

- محجر الحجر الجيري هـ

- الجيري تكنولوجيا كسارة

- مصنع كسارة الفحم جاسا جامبار

- حجر الرول الجزائر

- Cement Machinery Colabration

- Mobile Crusher Safety Toolbox Talk

- Crushing Of Ores Flow Diagram

- Lucky Cement Factory Pezu

- Freeport Indonesia Jenis Alat Pemecah Batu Coal Russian

- Grinding Wheel Learn

- Mineral Resources And Loions In Nigeria

- Free Cartoon Mountain And Mining Picture

- Brazil Tungsten Ore Crushing Plant

- Crusher Mesin Snorinco

- One Tier Mill Lab

- Republic Of Belarus Small Ore Crusher

- Of 6mm Rerolling Mill

- Cone Crusher Sleeve Drawing

- Grilled Kiln Firing Kiln Operation