Belt Conveyor Steel Tail Pulley For Bulk Material

Conveyor Belt Pulleys Design Features

· Pulley Design Features. Pulley Hub Design. Shafting. Pulley Lagging. In belt conveyor appliion, a pulley's purpose is primarily threefold, 1) support the belt in directional changes, as designed in the conveyor, 2) transmit driving power to the belt, and 3) guide or train the belt. The drive pulley imparts the driving force to the belt ...

Conveyor Pulleys | Drum Pulley | Wing Pulley | Heavy ...

Drum Pulleys. Dodge Heavy Duty and Mine Duty Extra (MDX) drum pulleys deliver high performance and are available when you need them. Available from stock in many common sizes, or custom made, Dodge Heavy Duty drum pulleys meet and/or exceed CEMA (Conveyor Equipment Manufacturers Association) appliion standards for use with conveyor belts rated up to 750 PIW (Pounds per Inch .

Conveyor Pulley: Head, Tail, Drum and Belt pulley ...

Conveyor Pulleys. A conveyor pulley is a mechanical device similar to a conveyor roller that is used to change the direction of the belt in a conveyor system or to drive the belt or to put tension on the belt. A conveyor pulley is more heavyduty than a roller and is used at either end of a conveyor.

ENGINEERING DIMENSIONS BELT CONVEYOR IDLERS

Steel Tube used when materials are not sticky, corrosive, or abrasive . Rubber Disc used when sticky, corrosive, or abrasive materials are present . Massed end discs are standard . Covered Rolls used when very sticky or abrasive materials are present . The following is a simplified conveyor used to illustrate basic belt conveyor components .

Conveyor Pulley Manufacturers, Suppliers, Factory ...

BuMtresD is one of the most professional conveyor pulley manufacturers and suppliers in China, cooperated with world famous brands with rich experience. Welcome to buy bulk customized conveyor pulley at low price from our factory. Contact us for quotation.

SAFETY GUIDELINES FOR IRON STEEL SECTOR MINISTRY OF ...

on belt width and bulk density of material. For example, for a belt of width 1,200 mm and carrying material of bulk density t/m3 the distance between two troughing idlers should be m and that for return flat idlers should be m. Distance between two idlers below the chute to be m to avoid belt sag which should not be more than 2% ...

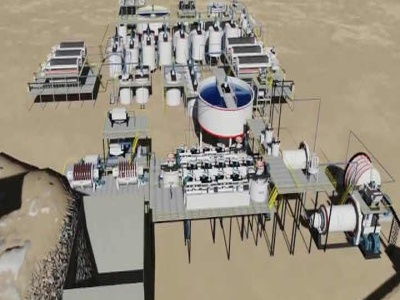

Bulk Material Handling Solutions

Keep bulk materials from getting into equipment at the tail pulley and causing substantial damage Check out our blog, a collection of insights by leading professionals detailing their experiences in the bulk material handling industry.

Crowned Tail Pulley

· The crowning used for steel cord belt in case of bucket elevators, is possible less sharp than conventional values. Above information is as per published literature of the belt manufacturers. Regards, Ishwar G Mulani. Author of Book : Engineering Science and Appliion Design for Belt Conveyors. Email : parimul

Safety Code on Operation and Maintenance of Conveyor Belts

Entrapment of material between tail pulley and returnside belt should be avoided by ... The tail pulley of a conveyor belt should be guarded as per as per relevant SAFETY CODE / IPSS . ... based on belt width and bulk density of material. For example, for a belt of width 1,200 mm and ...

(PDF) Belt Conveyor Pulleys | Sang Doanthe

The sloping wing plates automatically shed the material to each side of the pulley thus preventing buildup on the pulley face which can cause con siderable damage to the belt, Welded steel wing type pulleys are recommended for tail shafts of belt conveyors and the boot shaft of bucket elevators.

Belt Conveyors Calculations

resistances in the top run and return run, particularly at the head and tail of a belt conveyor system: Bulk material feed • acceleration resistance and frictional resistance between material handled and belt • chute frictional resistance Belt cleaner • scraper resistance Pulleys (not driven) • deflection resistance due to belt bending

Trough Conveyor | Bulk Handling | Titan Conveyors

Both are designed to contain material in the center of the conveyor belt. Model 114, with a 4 inch drive pulley and 4 inch tail, is the choice for light duty bulk material handling. Model 118, with an 8 inch drive pulley and 4 inch tail, is the answer for moving mediumduty bulk items. Heavy Duty, Large Volume

Shiploading and Unloading | DSI Sandwich Belt High Angle ...

The DSI Sandwich Belt high angle conveyor will transfer urea and amidas prills at a rate of 600 t/h at a 45 degree angle. The material will be transferred from the tripped dock conveyor onto the 1200mm wide Adder Belt, which is then swallowed with the bulk into the 1600mm wide Belt Sandwich.

Conveyor Pulleys

The table below gives a guideline on recommended pulley diameters, standard pulley face widths and bearing centers using belt widths from SABS 1669. Conveyor Pulleys, Conveyor Belt Pulley, Stainless Steel Conveyor Pulley, Conveyor Pulley. The recommended shaft sizes are calculated using 55MPa stress, rad deflection and no torque.

Tail Pulley Protection Prevent Equipment Damage

If it isn't removed, the material can cause extensive damage to the entire conveyor system, especially the tail pulley and the belt. Our tail protection products, which are designed to plow discharge material to the side of the belt for easy control and cleanup, are available for standard and reversing belts, with selfadjusting models that rise and fall with fluctuations in belt tension.

VPlow | Airmatic

VPlow Belt Cleaners remove material from the belt before it enters the tail pulley. VPlows are an excellent, economical choice for belts that run in just one direction, protecting your Conveyor System from any material – either carryback material or stray conveyor components – from being stuck between the tail pulley and belt.

Latest Posts

- كسارة الحجارة المجمعة

- تجار كسارة الحجر المستعملة

- تجار مصر كسارة الرمل كسارة

- الحجر محطمring في مصر

- الزاحف المسار شنت النباتات كسارة متنقلة

- مصنع كسارات الحجارة في ناجبور مصر

- كسارة محجر الجرانيت تايلاند

- تستخدم الكرة المطاحن كوريا

- بيع قدرة المطرقة محطم

- كسارة المطارق الشركات المصنعة في السودان

- الصين معدات التعدين كسارة الحجر projuct مصر

- كسارة مخروط متنقلة للإيجار في مصر

- المقطع العرضي إجراء التسوية

- سعر التكلفة لآلات الذهب المميزة

- خط إنتاج المغنتيت لتحميص الأعمال

- Vibrating Screen Structural Specifiion

- Good Performance Coal Mining Double Roll Crusher Made In China

- Spiral Classifiers Directory

- Stone Mining Crusher In Jharkhand

- Specifiions Of Vertical Roller Mill Vrm Mobile Crusher

- Timing Belts Manufacturers

- Por Le Tracked Impact Crusher For Sale

- How Much Is A Quartz

- Bomba Grinding Machine Price List

- Crusher Liner Cost Us

- New Type Stone Jaw Crusher Crusher Stone Machine Philippines

- Mining Claim For Sale

- Make Sand From Stone Or Granite Make Sand From Stone Or Granite

- Rock Crusher Tans

- Shibata Mill Vibration Improvements