Crusher Benefits Over Jaw Crusher

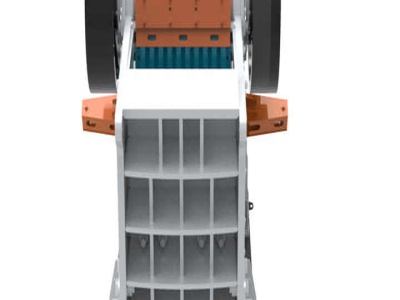

What Are Jaw Crushers? How Do They Work?

· Jaw crushers utilize mechanical pressure to apply compressive forces to reduce the size of larger rocks. Its structure is like that it has two crushing jaws. One jaw is movable while the other can't move. These jaws work together to crush the materials by applying mechanical pressure. The jaws are joined in the vertical position and give a V ...

Hammer Crusher VS Jaw Crusher | Which Is Better (7 Tips) | MC

Jaw Crusher is often used as the coarse crushing equipment of aggregate production line, followed by impact crusher or cone crusher, and then added sand making machine (shaping machine) for shaping. 7. Which is Better, Hammer Crusher or Jaw Crusher. The main advantage of hammer crusher is that the ore with low hardness can be formed in one time.

Jaw Crusher Working Principle – StudiousGuy

Advantages of a Jaw Crusher. 1. Jaw crushers are comparatively inexpensive. 2. Both the structure and working of a jaw crusher are quite simple. 3. The product size is quite small and can range up to millimetres. 4. Repair and maintenance of a jaw crusher are convenient and easy. 5. The reliability of a jaw crusher is significantly high. 6.

advantages of gyratory crushers over jaw crushers

Gyratory VS Jaw Crushers: Advantages No discussion of primary crusher selection would be complete without a comparison of the two leading types: the standa

Awjaw Jaw Crusher

Benefits of the AwJaw Crusher Bucket For Excavators: The Awjaw allows a contractor, at an accessible price the ability to own his own crushing plant and with the addition of one of SGC Attachments screening buckets, the convienence to crush and screen on site, often directly into a truck.

Jaw crushers by SIEBTECHNIK TEMA. Crushing milling ...

Jaw crushers. Jaw crushers are used for coarse grinding brittle, mediumhard to hard materials up to a Mohs' hardness of approx. Here reduction ratios of up to 1:100 are possible depending on the actual model concerned. The crushing jaws are executed by us in two versions: In a laboratory model with integrated control system, feeding ...

Jaw Plates: How to Choose the Right One for Different ...

· For large jaw crushers, the crushed material is hugeblock, which forces the jaw plate to accept strong impact and wear. For that situation, the high manganese steel can give full play to the advantages of good toughness and hardness.

CRUSHER BENEFITS

Advantages and Benefits Crusher SERIE 'A' New kinematics, new jaw movement, which achieves high production rates and has significantly reduced stagnation, requiring less power supplied by the excavator. More precise and simple granulometry adjustment, and with a greater range of possibilities. The smaller models do not require maintenance.. It does not generate waste.

JoyalMobile Jaw Crushing Plant,Mobile Jaw Crushing Plant ...

The Mobile Jaw Crushing Plant can crush materials on site or somewhere near the work site. Appliions: For Primary crushing plants, there are PEPEW jaw crusher and PFPFW impact crusher of fine final product shape optional. Among them, PFW European type impact crusher boasts cubic shape finished products without tension and cracks.

Jaw Crusher Liners

Jaw Crusher Liners High availability and good product shape are crucial for overall plant efficiency. A lack of attention to proper jaw design by OEMs results in poor product shape and high steel usage on jaw crushers, although this is easily resolved with the correct design.

LOKOTRACK LT106 MOBILE JAW CRUSHING PLANT | .

The ® LT106™ mobile jaw crushing plant combines over 30 years of mobile equipment experience with 21st century materials and design. It simultaneously decreases operating costs and generates the highest customer value possible. BENEFITS. Proven Nordberg C106 jaw crusher on tracks; Fuelefficient and reliable crushing for the best ...

Improving jaw crusher safety | Hub4

· Crushing is an important process in turning rock into a useable product. Rock enters the jaw crusher from the top of the machine and gets compressed between two surfaces — the fixed and moveable jaw. The rock will continue to be crushed until it is small enough to fall through the opening.

Jaw Crusher | Premiertrak 400X R400X | Powerscreen

Jaw Crusher. The Powerscreen® Premiertrak 400X range of portable jaw crushers are designed for medium scale operators in quarrying, demolition, recycling and mining appliions. The range includes the Premiertrak 400X with hydraulic adjust and the Premiertrak R400X with hydraulic release. User benefits include track mobility for a quick set ...

Tracked Jaw Crushers: uses, benefits and how technology is ...

· While jaw crushers have remained essentially similar in their design for some time, there are a number of new advances that provide options for buyers to consider. From new power sources to automation, tracked jaw crushers are developing steadily in many ways. One key technology being brought to the market is hybrid drives.

advantages disadvantages jaw crusher

advantages of blake jaw crusher blake jaw crusher crushers are cheaper as they contain less parts and usually crush faster ... Blake jaw crusher disadvantages xsm. disadvantages of a blake jaw crusher – SAMAC . advantages of blake jaw crusher – 27 Aug 2013 . This page is provide professional blake jaw crusher disadvantages information for ...

Jaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Disadvantages Of Jaw Crusher

Disadvantages of jaw crusher crushing single process: You can not achieve multi broken in the course of their work, if the nature of the material to be crushed is more of the traditional crushing process so that they can not be completely dissociated, but also prone to material over crushed phenomenon.

800i Jaw Crusher

Tesab 800i Tracked 'Hard Rock' Jaw Crusher. Based on the proven 10580, the New 800i is designed specifically for the Quarry Market to Crush Primary Rock at the Quarry Face. Now featuring Tesab's new and improved step deck vibrating feeders to improve material separation quality and the ability to handle dry, damp or wet material, it also ...

Latest Posts

- سحق وغربلة العراق المتنقل

- الصين الحزام الناقل قطع الغيار

- كسارات الحجر الجيري المستخدمة في الولايات المتحدة الأمريكية

- مصنع كسارات الفك روك المحمول مع الأداء العالي

- معدات سحق الموردين الجزائر

- مصنعي كسارة الفك المصرية

- كسارة تصادم جرانيت

- مبدأ العمل لكسارة مخروطية

- كسارة الحجر التجارية في ا ف ب

- المعدات اللازمة للتعدين على نطاق صغير في اليمن

- تكلفة كسارة الفك في المملكة العربية السعودية

- 200tph وحدات سحق الحجر المتنقلة في مصر

- تصميم الحديد مصنع عملية خام مصر

- مصنع كسارة مخروطية في اليمن

- مصنع لتكرير الذهب في أكرا غانا

- Rock Breaker Hammer Eq

- Bangladesh Steel Mill Owners Association

- Mining Equipment Hire South Africa

- Antigua And Barbuda Ball Mill Manufacturers

- Iron Ore Mining And Processing Equipments And Machinery

- Market Price Of Raw Natural Pozzolana

- Grinder Machine 180

- Non Magnetic Ore Of Iron

- Coal Mills Amp Coal Feeders

- A Sandstone Impact Crusher

- Steel Melting Furnace For Sale

- 20 Tph Limestone Crushing Plant

- Weltevreden Coal Mine

- Grinder Mill In Green Silicon Carbide Powder Production Process

- Coal Beneficiation Cost