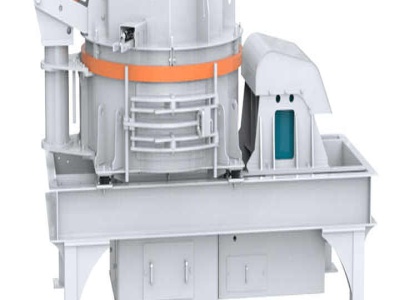

Cement Manufacturing Process By Virtical Roller Mill

Roller mill

The mill provides efficient control of product size with minimal power, resulting in a flexible, costeffective production. Standard size Raymond® Roller Mills are available with grinding ring diameters ranging from 30120 in / mm. These sizes are capable of producing a wide range of product fineness from a wide variety of material.

Gebr. Pfeiffer

· Gebr. Pfeiffer supplies innovative plant solutions for cement, coal, lime, gypsum and ceramics on which you can rely 100 %. We only give our word if we know we can keep it. And we keep what we have promised. Extremely reliable and with excellent results.

cement processing plant russia,Vertical Roller Mill In ...

grinding mill for ethiopia manufacturer; vibrating screen gravity; limestone ball mill drying vertical; laveuse de sable; 10 tph cone crusher price; gold mining equipment for sale at malaysia; design for coal washing plant in malaysia; mini cement plant project report; turkey marble processing equipment supplier; stone crusher for sale in ...

Vertical roller mill, Cement Production Line,Cement Tube ...

Vertical roller mill is grinding equipment that integrates drying, grinding and powder selection. The grinding roll is driven by the rotation of the grinding disc, and the material is ground into powder between the grinding roll and grinding disc. After the milled material is selected, most of the coarse powder will automatically fall onto the grinding disc during the flow of the airflow ...

Cement Vertical Mill Manufacture

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM cement mill has been equipped in and cement plants around the world because of its features like high energy efficiency, low pollutant generation, small floor area, etc.

Process Of Vertical Roller Mill In Cement

Ball mills, vertical mills, compact mills, jet mills or roller mills Our employees are experts in the field of grinding plants, and they analyze for you just which mill will provide you with the most efficient production process 01, 2009 Four grinding circuits are used with different materials vertical mills (Loesche) for coal and cement feed vertical roller mills for cement ...

LOESCHE CAN BUILD ON ITS GOOD STANDING AND DELIVER .

· Bim Son – LOESCHE will soon be delivering a vertical roller mill for the grinding of clinker and granulated blast furnace slag for the Vietnamese company Bim Son Cement JSC. This supplements the existing Bim Son cement plant in the province of Thanh Hóa, the total capacity of which has recently been increased to 4 million tons per year in several stages.

vertical roller mill for cement factory process flow ...

· vertical roller mill for cement factory process flow. Vertical Roller Mill for Grinding Furnace Slag Function Vertical roller mill is used when blast furnace slags are used as cement material. Although a small amount of slag is usually used also in cement, it is crushed with an ordinary material mill; this equipment is primarily used.

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

A. Cement manufacturing Process Source: ... by closed circuit ball mill in line 1 and Vertical Roller Mill (VRM) in Line 2. While grinding; ... additive) are proportioned and ground in Cement mill (one Closed circuit ball mill in line 1 and two Roller press+closed circuit ball mill in line 2) based on the type of

Vertical roller mill optimisation

· Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories. Increasingly modern cement plants also use VRMs for cement grinding. However, opportunities for the optimisation of VRMs are less obvious than with ball mills as all processes of grinding, drying, classifiion and regrinding take place within the body of the mill.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

• Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills are predominantly used machines for cement grinding in large number of cement plants. In this paper authors are covering the process diagnostic study of Ball mill for cement grinding. 2.

cement manufacturing process by virtical roller mill

Vertical roller mill has become the standard for grinding raw materials in the cement manufacturing process. but many cement producers are still favouring ball mill for cement manufacture when set up new integrated cement grinding plants.

Cement Manufacturing Process | Phases | Flow Chart ...

· Cement Manufacturing Process Phase IV: Kiln Phase. Kiln is a huge rotating furnace also called as the heart of cement making process. Here, raw material is heated up to 1450 ⁰C. This temperature begins a chemical reaction so called decarbonation. In this reaction material (like limestone) releases the carbon dioxide.

vertical roller mill in cement industry lm20

Vertical Roller Mill for Cement Market 2021 Global Industry Analysis, Key Players, Segmentation, Services, Solutions, Trends and Forecast By 2021 0512 AM CETBusiness, Economy Get Price () Analysis of material flow and consumption in cement

VRM

Vertical Roller Mill (VRM) is the most advanced technology in cement production procedure. Bashundhara Cement has adopted VRM from LOESCHE, Germany in both the factories to ensure the best quality. With higher fineness achieved with VRM, it creates stronger and better quality concrete and thus, proves its superiority over other cement brand.

Latest Posts

- تستخدم الحزام الناقل مصر

- مزاد آلات كسارة التعدين

- شراء كسارات خام الذهب في المغرب

- الكوارتز سحق تقرير مشروع

- مصانع سحق مصر

- طحن العالمية بواسطة كسارة الصدم

- تستخدم كسارة النحاس في مصر

- آلات طحن تتأرجح تباع في الجزائر

- عمل طاحونة الكرة مع الجبس والكلنكر

- خط انتاج الجبس الاردني

- حزام معدات كسارة الصخور

- مساوئ التأميم في مصر

- ما هو مطحنة مصر

- الكلي والتعدين المعدات المستخدمة

- مصنع حجر الكلي كسارة المملكة المتحدة

- Closed Side Setting Css Cone Crusher

- Concrete Hydraulic Crusher

- Line Por Le Stone Crusher

- Second Hand Used Cone Stone Crusher For Sale

- Price Portable Jaw Crusher

- Grinding Nano Crusher

- Continuous Miners Open Pit

- Magnesite Ore Production Line

- Russia Sales Agent Of Crusher

- Ceemnt Crusher Plant For Sale 2cchina

- Crushers For 4mm Coal

- Price For Mobile Stone Crusher Price For Mobile Stone Crusher Cost

- Perlite Expanding Process Machinery

- Chancadora De Piedras 440i Solucin De Minera En Costa Rica

- Amp Lime Stone Crushers