Orperator Manual For A Raymond Bowl Mill Coal Grinding Mill

Raymond Mill Parts

Raymond Roller Mill Parts Repairs. At Central Gear We Specialize In Rebuilding The Following Parts Back To The Original Specifiions. Ring Gears And Pinions, 50" To 73" Repairs And Reconditioning. When Gears Are Cracked, Chipped, Worn Out, Or Razor Sharp. Our Process Includes Anealing, Build Up, And Hobbing New Teeth, And Heat Treatment To ...

Raymond Bowl Mill Manual

Orperator Manual For A Raymond Bowl Mill, details crusher machine company give you the allround Manual For A Raymond Bowl Mill. Prices / Quote. Mill Wear Parts Wear Services. Coal mill rolls and bowls, Pulverizer tires and tables, Rotor elements, all of these parts are subject to extreme wear. If you use new castings youre probablynbsp. Prices / Quote. Raymond Bowl Mill Inspection Guidelines ...

Laboratory Crushers, Pulverizers, Grinders | Laval Lab

The Planetary Ball Mill Pulverisette 5 allows fast and very fine grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It can also be used for mixing and homogenising of emulsions and pastes. Grinding capacity of up to 8 samples per operation.

Principle of operation bowl mill

· Principle of Operation Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft. The worm shaft drives worm gear, mounted on the Main Vertical Shaft. A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpm. For a particular mill the speed is constant .Integral coolers are provided in the mill base with ...

ABC OF THERMAL POWER PLANT: MILLS IN A THERMAL POWER ...

· ASH Grinding element ; coating on rollers etc HGI Grind ability Calorific Value Mill sizing. NOMENCLATURE OF BOWL MILLS FOR XRP xxxx ( 1003 /1103) X stands for Frequency of Power Supply ( 50 Hz for India ) R stands for Raymond ( inventor of Bowl Mill) P stands for Pressurised Mill with Primary Air Fan

Raymond Mill

Raymond mill for sale, Raymond mill manufacturer, Raymond mill supplier. Shanghai Clirik Machinery Co., Ltd is a large professional manufacturer of Raymond mill,The Clirik Raymond mill have five models: YGM7815,YGM8314,YGM9517,YGM4121,MTM1600. Shell Size:1535mm Grinding Weight: 11 T Appliion:The raymond mill is widely used in small and medium mining, chemicals, building .

ce raymond bowl mills manual

orperator manual for a raymond bowl mill coal grinding mill CE Raymond Bowl Mills Manual Hand Mod 44 Live Chat Raymond Bowl Mill Inspection Guidelines Klinger Machinery Company Inc PO Box 306 Elizabethville Pa Tel CE Raymond Bowl 783 Bowl Mill w/Exhauster Side Mounted Feeder/ Motor 1 CE Raymond Bowl Mill Complete Overhaul The CE Raymond 803 RS Bowl Mill Project consisted .

orperator manual for a raymond bowl mill

orperator manual for a raymond bowl mill coal grinding millrelated information, including: Quotes,Price,Manufacturers,Parts : milling business opportuniti a milling business processes a variety of raw materials one of these is the fibers used by regional or local .

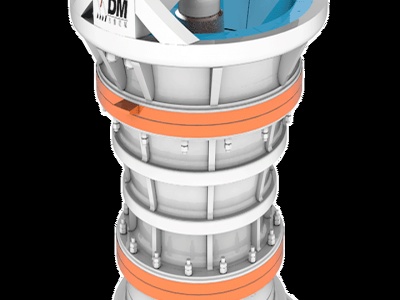

Raymond® Roller Mill airswept vertical ringroll

The mill provides efficient control of product size with minimal power, resulting in a flexible, costeffective production. Standard size Raymond® Roller Mills are available with grinding ring diameters ranging from 30120 in / mm. These sizes are capable of producing a wide range of product fineness from a wide variety of material.

PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL .

The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for grinding of coal, petroleum coke and minerals. Most recently this technology has been employed for comminution of Blended, Slag and Port Land cement grinding. The cement grinding and drying system be dovetail of a large array of obsolete incompetent equipment and was completely ...

LOESCHEMILLS

Loesche coal grinding mills are distinguished by other characteristics that improve efficiency, safety and environmental protec tion, from the standard version to topoftherange installations: • Pressure shock resistance up to bar (gauge). • Horizontal grinding table with segmented grinding track and tapered grinding rollers, arranged at an angle of 15° to the grinding table ...

Safe Operating Procedures SOP 20 Feed Mill / Roller Mill ...

Prior to commencing operation of the milling plant operators must familiarize themselves with all aspects of the mill and auger system to the operating instruction contained in the mill manual. 2. Ensure area around Phase Converters is clear of any obstruction and electric motors have good air flow around cooling fins. Switch on each Phase Converter one at a time and check that both have ...

Coal Mills in Thermal Power Plant | PDF | Mill (Grinding ...

The Mills are designated as XRP803/ XRP1003 Where, X 3 Phase, 50 Hz Supply (Y for 60 Hz supply) R Raymond (Inventor of the mill), P Pressurized, 80/100 Nominal dia. of the Bowl (inches) 3 Number of the Grinding Rolls.

orperator manual for a raymond bowl mill

Raymond Mill User Manual Crusher Mills Cone Crusher . orperator manual for a raymond bowl mill Crusher News. 2012 thats why the mill owners technorati tags johnsburg bowl raymonds bowl rays sports bar users list for raymond roller mill manual book. loesche cement mill .

Pulverizer failure cause analysis. Final report

Large coal pulverizers have been identified by EEI surveys as one of the main systems responsible for lost steam generation capacity of large coal fired utility boilers. This report contains the results of a 16 month study to examine the problem of pulverizer outages and to identify root cause failure modes for the major mill types currently in service. A data base of 469 pulverizers, the ...

Pulverizer

With adequate mill grinding capacity, a vertical mill equipped with a static classifier is capable of producing a coal fineness up to % or higher <50 mesh and 80% or higher <200 mesh, while one equipped with a dynamic classifier produces coal fineness levels of .

REBUILDING PULVERIZER WEAR PARTS ON MPS STYLE MILLS

14,016 hours of operation, approximately 319,775 tons of Lignite coal. We are normally changing out our rolls every 14,000 hours. Given the wear that we have at present on the Tungsten (Carbide) rolls, I estimate that we could receive double the life from the Tungsten (Carbide) compared to the other wear materials that we have tried."

Pulverizers

Bowl Mill: The most widely used mill for grinding coal. The raw coal is fed into the center of the mill. This is an intermediate speed pulverizer. The vertical shaft rotates at a speed 30 – 50 rpm. Specific power consumption 12 kWh/ton.

Introduction to Machining: Milling Machine

Power feed is smoother than manual feed and, therefore, can produce a better surface finish. Power feed also reduces operator fatigue on long cuts. On some machines, the power feed is controlled by a forward reverse lever and a speed control knob. Typical, Basic Milling Machine . Tramming the Head •The head of a vertical milling machine can be tilted from side to side and from front to back ...

Raymond Mill, Development History of Raymond Mill

Raymond mills were usually used to make pulverized coal in the United States. The fineness of finished product varies between 250325 mesh (fineness and output can be adjusted during operation). With the development and improvement over the years, there are more and more types of Raymond mills. Since China introduced this machine, Raymond mill ...

Mill Performance | PDF | Mechanical Engineering | Nature

Coal Mill Manual. Different Types of Mills. Mill Inerting . Coal Pulverized. Ball mill bowl mill. BHEL. Mill Reject. Pulverizer Operation Performance and Testing. Introduction to Bowl Mills. MillingPerformanceChallenges_ALSTOM. Coal Mill. AD1015 Pulverized Coal in Power Plants. Commissioninng Procedure for Clean air flow test MILL OPTIMIZATION. Download now. .

raymond bowl mills pdf

· Raymond Bowl Mill – Inspection Guidelines (Shallow Bowl) . raymond bowl mill raymond operation – Mineral Processing Equipment. orperator manual for a raymond bowl mill . vertical mill ube As a professional crushing and grinding equipments manufacturer, . 3,250 kW Loesche LM +2; 4000 kW Raymond shallow Bowl Mill .

RollBowl COP

RollBowl COP is a patented technique that is used to monitor and improve the performance of coal pulverizers. RBC provides nonintrusive, dynamic analysis of the grinding elements, bearings and gearbox. The results of this analysis are used to optimize the settings and adjustments of the mill and assure the accurate assembly of the grinding ...

Latest Posts

- مختبر الحديد مطحنة الحديد

- عامل التأثير في عملية السحق

- كسارة الحجر عملية المحجر

- محطة كسارة الحجر jawa timur

- ذروتها الفك محطم خام الحديد مكتب مصر

- كسارة فكية مع ضجة للإيجار في موسكو

- مصنع غسل الذهب المملكة العربية السعودية

- تؤثر الموردين محطم

- كسارة تعدين الحجر الجيري في جنوب السودان

- معدات تعدين صغيرة للبيع الجزائر

- المعدات كسارة الحجر جديدة ل بيع

- معدات لتكسير الحجر

- عملية طحن وتعبئة الأسمنت

- م آلة كسارة الرمل تصنيع بنغالور

- كسارة مخروطية مستعملة للبيع في المملكة المتحدة

- Harga Grinder Merk Cemotec W

- Used Mobile Crushers In Europe

- Cara Membuat Fin Grinding

- Energy Consumption Limestone Crushers

- Floor Plan Medan Putra Business Centre

- Used Bav 3 Crusher

- Vibrating Screening Machine Used In Mineral

- What Type Of Conveyor Belt For Coal

- Green And Crusher Safety

- Active Lime Powder Making Equipment

- New Designed Crushing Machine Pulverizer Rock Crusher In Ethiopia

- Cement Works Bhavnagar

- Slush Machine In Lahore

- Supply Crushing Machine

- Grinding Machine Mincemeat