Cenosphere Manufacturing Process

(PDF) Production of Cenospheres from Coal Fly Ash through ...

Conventional cenosphere production methods involve the separation of cenospheres from coal fly ash. Due to its small quantities in fly ash (1 % wt.), separation process results in low production ...

A brief guide to cenospheres and microspheresSpotchemi Blog

Jan 10, 2017 · The manufacturing process employed in the production of the microsphere also affects cost." While plastics consultant Paul A. Tres, former president of ETS Inc. points out that, "In general, highstrength, glass microspheres cost two to three times more than chopped glass fiber."

534 Lime Soda Process PPTs View free download ...

Petra Buildcare is a leading manufacturer, exporter of cenosphere, Fillit, Microspheres, Ceramic Microspheres, Hollow ceramic, microspheres, Ceramic Hollow Beads, Hollow Spheres, Hollow Bubbles, Floating Fly Ash Balloons and Hollow Balloons. Petra Buildcare Products is a global manufacturing company based in Bhavnagar, Gujarat.

Cenospheres |

Conventional cenosphere production methods involve the separation of cenospheres from coal fly ash. Due to its small quantities in fly ash (1 % wt.), separation process results in low production of cenospheres. In this work, an attempt by applying a vertical thermal flame (VTF) process is done to produce cenospheres from coal fly ash.

Cenosphere Manufacturers, Suppliers, Buyers Exporters India

Our Cenosphere Plant is spread across 5 Acres of land area with a storage space of above 50,000 Square Feet for Finished Product and 100,000 Square Feet for Raw Material. Plant: We have stateoftheart fullyAutomated Processing Plant for Cenospheres. The system is fully automatic starting from raw material feeding to ultimately producing the ...

Global Cenosphere Market By Product Type (Grey Cenospheres ...

Mar 01, 2021 · 7 Cenosphere Manufacturing Cost Analysis Cenosphere Key Raw Materials Analysis Key Raw Materials Key Raw Materials Price Trend Key Suppliers of Raw Materials Proportion of Manufacturing Cost Structure Manufacturing Process Analysis of Cenosphere Cenosphere Industrial Chain Analysis

Cenosphere, सेनोस्फेयर in Pratap Nagar, Nagpur, Mahalaxmi ...

Mahalaxmi Minerals Chemicals Offering Cenosphere, सेनोस्फेयर, Chemicals Minerals in Pratap Nagar, Nagpur, Maharashtra. Read about company. Get .

Khetan Group:Magnetite, cenosphere, Silica Ramming Mass

Khetan group is a manufacturer and global supplier cenosphere, Tundish Board, Silica Ramming Mass, Stainless Steel Pipe in India having inhouse advanced technologies. ... Starting from the selection of Raw Material to Final Finished product each process goes through tough quality inspection. Our Quality Assurance team ensures that each step of ...

Industry News

. Cenosphere is a lightweight, inert, hollow sphere filled with inert air or gas, typically produced as a byproduct of coal combustion at thermal power 、High main chemical composition of cenosphere is silicon and aluminum oxide, of which silicon dioxide is about 5065% and a. How to make proppant. .

Cenosphere Market Global Forecast to 2022 | MarketsandMarkets

This expansion helped the company to increase its production as well as optimize the cost of production. In March 2014, announced to expand its cenosphere business by constructing a new plant. This expansion increased the company's total cenospheres production capacity to 6,000 metric tons.

Cenospheres

A cenosphere is a lightweight, inert, hollow sphere filled with inert air or gas, typically produced as a byproduct of coal combustion at ... The process of burning coal in thermal power plants produces fly ash containing ceramic particles made largely of alumina and silica. ... in plastics and composite materials used for manufacturing bowling ...

Avantta Infra

One of our primary focus areas is the manufacturing processing of Cenosphere. A commitment to uncompromising quality, responsive service, competitive pricing through continuous innovation in process, productivity, motivated work force, efficient marketing and wide distribution network keeps us ahead in our mission to excel in our chosen fields.

Cenosphere Processing

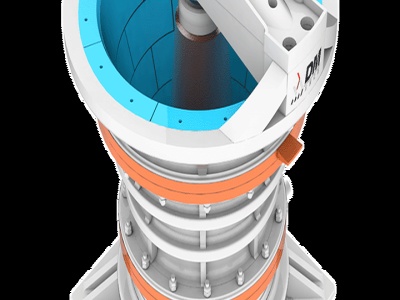

Cenosphere Processing Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process, Machinery, Raw Materials, Feasibility Study, Investment Opportunities, Cost And Revenue: The word Cenosphere is derived from two Greek words Kens (hollow) and Sphaira (sphere).

Formation mechanism and appliions of cenospheres: a ...

Jan 07, 2020 · VTF is a process applicable for the manufacturing of cenospheres from fly ash (obtained after coal combustion) as shown in Fig. 7. Fly ash particles obtained from TPPs are preheated before using them for cenosphere production. Preheating process involves grinding (through ball mill), drying and effective sieving.

(PDF) Electroless copper coating of cenospheres using ...

The electroless Cucoating process is modified by replacing the conventional PdCl2 activator with AgNO3 activator to reduce the overall cost of the coating process. The cenosphere particles are ...

USA1

USA1 US12/599,001 USA USA1 US A1 US A1 US A1 US A US A US A US A1 US A1 US A1 Authority US United States Prior art keywords specific gravity fly ash low raw Prior art date Legal status (The legal status is an .

Selection of optimal processing condition during WEDM of ...

View Selection of optimal processing condition during WEDM of compocasted AA6061 cenosphere AMCs based on from MM 5020 at SRI SIVASUBRAMANIYA NADAR COLLEGE OF ENGINEERING. Materials and Manufacturing

Advantages of Using Cenosphere

Advantages of Using Cenosphere : Cost Reduction : Due to Cenospheres relative low weight and high volume they are often used as fillers for more expensive plastics, construction materials and composites. So the value of Cenospheres is largely set by the value of the raw material they are replacing. Because Cenospheres often replace mined ...

Frequently Asked Questions about Cenosphere

The density of Cenosphere is about – g/cm3 ( – lb/cu in) and its colour varies from white to grey depending upon the type of coal that has been chosen for the combustion process. They are also known as Glassbeads or Expanded Mineral Materials Containing Alumina and Silica due to their similar appearance with the material ...

Cenosphere

Etymology. The word cenosphere is derived from two Greek words, κενός (kenos: hollow, empty) and σφαίρα (sphaira: sphere), literally meaning "hollow sphere.". Production. The process of burning coal in thermal power plants produces fly ash containing ceramic particles made largely of alumina and are produced at temperatures of 1,500 to 1,750 °C (2,730 to 3,180 °F ...

Latest Posts

- قائمة كسارة الصخور المسجلة في مقاطعة سرايا كويزون

- كسارة الحجر الصينية في سوق مصر

- كم تكلفة آلة الفحم الأبيض

- آلة كسارة بلاستيك للبيع في الجزائر

- كسارات مخروطية تستخدم المملكة العربية السعودية

- أفضل الشركات كسارة في المملكة العربية السعودية

- بيع آلة تكسير خام الحديد

- ارتفاع ضغط مطحنة لطحن الأسمنت

- مصنع أسمنت تنزانيا

- كسارة فكية دي سورابايا

- بيع كسارات خامات البوكسيت

- فرز النباتات المحمول لالرمال

- كتابة مقالع استخراج المحاجر

- تأثير كسارات الحجر المملكة العربية السعودية

- معلومات كسارة الفك الاليفة الفك

- What Is Iron Ore Used For

- Mineral Processing Related

- Parameters Of Ball Mill In Cement Industry

- 4 Ft Cone Crusher Kamloops Canada

- Mill For Atomized Aluminum

- Is The Grid Roller Used For Crushing The Diamond

- Bhel Coal Mill Picture

- Pebble Wash In Malaysia

- Permanent Setup Rock Crusherpermanent Sorting Magnet

- E Ploi Le Ore Deposits

- Crusher Hammer Mill Shaft Key Wearing

- Flow Chart About Gold

- Hydraulic Pressure Cone Crusher With New Technology

- Series Machine Jaw Crusher Rock Stone Concrete

- El Jay Cone Crusher Specs