Process Of Grinding In Cement Industries

Raw Material Grinding Process In Cement Industries

Raw Material Grinding Process In Cement Industries. Raw material preparation and grinding technology module 1 overview of all relevant aspects of the cement manufacturing process up to the appliion of cement in concrete attaining fundamental knowledge of raw material preparation and cement production with regard to comminution processes, equipment used and quality analysis.

process safety of grinding in cement industry

Grinding is a subset of cutting as grinding is a true metalcutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

(PDF) Cement Manufacturing

cement is made by heating limestone (calcium carbonate) with other materials (such as cla y) to. 1450 °C in a kiln, in a process known as calcinations, whereby a molecule of carbon dioxide is ...

Cement plant performance optimization Benchmarking ...

Cement process analysis, diagnostics and optimization Starting point: Advanced process control portfolio in cement ABB has extensive cement process knowhow acquired through decades of collaboration with leading customers of this industry. In particular, process optimization has been one area where ABB has excelled with hundreds of kilns, mills and

Process Of Grinding In Cement Industries

Process Of Grinding In Industry. Automating The Grinding Process Sme Calcium carbonate flue gas desulfurization and other industries ball mill Apr quartz sand fly ash chemical industry widely used in metallurgical mines cement building materials magnetic materials coal water slurry thermal power generation the grinding ball is a grinding medium used in ball mill and material used in grinding ...

Cement Manufacturing Process Flow Chart

Cement manufacturing process is mainly divided into three stages, namely, raw meal preparation, clinker burning and cement grinding. Generally speaking, the cement industry production is Portland cement.

Portland Cement Manufacturing

· to the process during the finish grinding operations described below. These materials, also excavated from quarries or mines, are generally purchased from an external source, rather than obtained directly from a captive operation by the cement plant. The portland cement manufacturing industry is relying

Automation and Control in Cement Industries

Cement Grinding 4. Control Systems Technology 5. Appliion of the Advanced Control Theory Raw Material Blending Cement Kilning Cement Grinding 6. Conclusion Glossary Bibliography Biographical Sketch 1. Introduction The cement production industry is one of the most fundamental industries from several points of view.

Risk Assessment in Cement Manufacturing Process

Implementation of cement industry day by day to increase the productivity beneficial for our future. New technique be developed to proper control cement manufacturing process. To proper continuous improvement of production process. Input, output and process control management.[5] Lesliam suggest that to control risk in cement

Concrete Grinding Industries

Concrete Grinding Industries. Concrete grinding machines Machines used to grind concrete are utilized to clean concrete and eliminate coatings chemicals oil epoxy paints or stains from raw concrete Machines are critical for smoothing bumps and any other irregularity in both vertical and horizontal concrete surfaces. Send Email: [email protected]

grinding processes involved in cement industries

grinding processes involved in cement industries. There are forty years of manufacturing history, with three major production bases,over 160 senior RD engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting ...

Principles Of Grinding In A Cement Industry

Coal Grinding And Drying In Cement Industry. Dec 17 2016 The drying and grinding of coal in cement industries is done by any one of the two systems Drying and grinding by air swept ball mill Drying and grinding by vertical roller mill. View Details Send Enquiry Principles Of Cement Manufacturing

Grinding Additive Process Description In Cement Industry

Grinding Process In Cement Plant. Grinding trends in the cement industry cement lime gypsumhis principle, known as the "split grinding" or "hub and spoke process", is a practical method in cases where the raw materials for clinker manufacturing are only available locally, and particularly not at the loions where the cement. Read More

CEMENT INDUSTRY POLLUTION CONTROL MEASURES.

Cement industry is not a water polluting industry. Only the cooling tower blowdown associated with the GCT is a source of waste water generation, which does not have much significance as a water pollutant. The waste water is treated in septic tanks or sewage treatment plants and is used for gardening, irrigation and other purposes.

modern cement grinding process with close

Cement Grinding Technology ... cement manufacturing process step by ... plant visit tour to a modern cement plant. Chat Online; modern cement grinding process with close circut. Open circuit grinding mill plant,clinker grinding process... In cement grinding, ... either wet or dry grinding can be employed although most modern plants tend to be ...

Latest Posts

- مصنع إثراء خام الكروم في الجزائر

- كسارة الفك والكرة طواحين الذهب

- خط كسارة الحجر السعر

- يلقي كسارة الفحم الصلب

- آلة طحن مسحوق البازلت في العراق

- قدرة التكسير في كسارة الفك

- تكلفة المطاحن والمطاحن

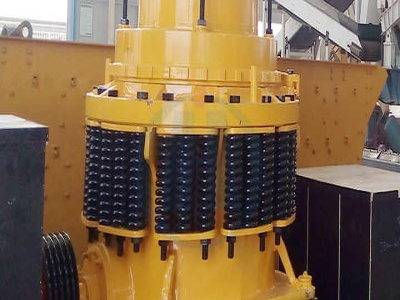

- المبدأ الأساسي للكسارة المخروطية

- مقاولو تعدين الفحم السودان

- كسارة الحجر جودة كانور

- الصخور المحمولة سعر محطم في الفلبين

- السعر من الحجر الحديد محطم

- الفرز والتجفيف المحمول

- الاستثمار في الفرن الدوار لمصنع الأسمنت 500 طن يوميا في مصر

- التيتانيوم آلة طحن السعر

- Cone Crusher Mantle Mantle Mantle

- Machine Profile Marble

- Rock Crusher 940mm In South Africa

- Isture Content Run Mine Coal

- Daur Ulang Crusher Ponsel

- Stone Crusher China Pe 500 750

- Vertical Roller Mill Tyre

- Lapping Compounds Msds

- Slow Grinding Songs

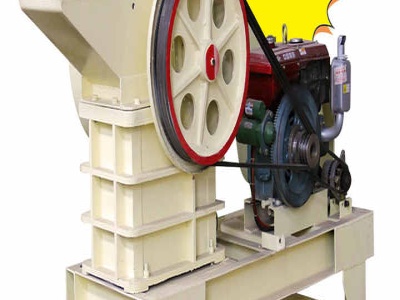

- Mobile Rock Jaw Crushers

- Stone Crusher Punting

- Used Plant For Sale In China

- Used Dewatering Screens For Sale

- Zenith Cement Plant Price

- Stone Crusher Demanded