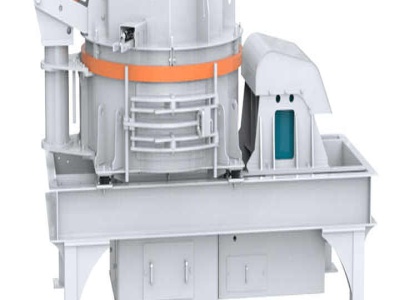

Iron Raw Material Ball Mill

Steel and raw materials

Steel and raw materials Fact sheet Steel is indispensable to our modern way of life and critical to economic growth. The intrinsic benefits of steel make it a sustainable choice in a growing number of appliions. Raw materials in steelmaking Key raw materials needed in steelmaking include iron ore, coal, limestone and recycled steel. The two main steel production routes and their related ...

Steel production residues

· Mill scale consists of oxides of iron, above all, but also the metal alloys that are included in the steel of which the mill scale is formed. Chemically, the mill scale can be compared with iron ore and can frequently be used in similar appliions, as a raw material on production of pig iron, ferrous alloys and cement.

CEMENT PRODUCTION AND QUALITY CONTROL A. Cement ...

4 Raw material Grinding and Transportation In this unit, the proportioned raw materials are being ground to the size of (10% residual on 90 μm sieve) by closed circuit ball mill in line 1 and Vertical Roller Mill (VRM) in Line 2. While grinding; the raw materials are being dried from 4% moisture

TECHNICAL NOTES 8 GRINDING R. P. King

material in the mill including the media which may be steel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the operating charge. Let Jt be the fraction of the mill volume that is occupied by the total charge, Jb the fraction of the mill volume that is occupied by steel balls and E the voidage of the ...

raw materials for extraction of iron

raw material extraction of iron ore from china. Iron Ore an overview ScienceDirect Topics. Iron ore extraction techniques. China is also the largest iron oreimporting country and imported about 65 of the worlds seaborne iron ore in 2013, followed by this chapter will focus on recent developments in the preparation of raw materials, balling, and firing for iron ore pellet production.

Industry Data

· The raw steel production tonnage provided in this report is estimated. The figures are compiled from weekly production tonnage provided by approximately 50% of the domestic production capacity combined with the most recent monthly production data for the remainder. Therefore, this report should be used primarily to assess production trends. The AISI production report "AIS 7", published ...

6. Minerals and industrial loion

Raw materials: Industries using weight losing raw materials are loed close to the rawmaterial sources. Ex: Sugar mills in India are close to the sugarcane growing areas. Iron and steel industries near coal fields or iron ore mines. 4. Transport: Adequate and cheap transport is essential for transport of inputs and finished goods. The Rhine valley in Germany has emerged as a manufacturing ...

TECHNICAL NOTES 8 GRINDING R. P. King

The geometry of a mill with conical ends is shown in Figure The total volume inside the mill is given by Vm 4 D2 mL 1 2(Lc L) L 1 (Dt/Dm) 3 1 Dt/Dm () The density of the charge must account for all of the material in the mill including the media which may be steel balls in a ball mill.

Metaluck Global Resources

Iron Raw Material For Steel Making. Metal Concentrates (Recycling Sources) Our team are experts in their field and have deep understanding on how the steel industry, metal recyclers and refineries work. Our products are used in, from steel mills, chemicals to metal refineries.

Raw Material

Iron Ore is the primary raw material in the manufacturng of steel. Steel is an alloy consisting mostly of iron and less than 2% carbon. Iron ore is, therefore, essential for the production of steel, which in turn is essential in maintaining a strong industrial base. Direct Reduced Iron ( also known as Sponge Iron) is a metallic product of iron ...

Ball Mills Of Irone Ore Mines

Ball Mills Of Irone Ore Mines. iron ore wet ball mill for iron ore mining plant a ball mill, a type of mill, is a cylindrical device used to grind or mix materials like ores, chemicals, ceramic raw materials and paints. ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

Powder metallurgy – basics appliions

Rod mills: Horizontal rods are used instead of balls to grind. Granularity of the discharge material is 4010 mm. The mill speed varies from 12 to 30 rpm. Planetary mill: High energy mill widely used for producing metal, alloy, and composite powders. Fluid energy grinding or Jet milling: The basic principle of fluid energy mill is to induce

Industry Data

· In the week ending on October 23, 2021, domestic raw steel production was 1,870,000 net tons while the capability utilization rate was percent. Production was 1,549,000 net tons in the week ending October 23, 2020 while the capability utilization then was percent. The current week production represents a percent increase from the ...

TMS International

Raw Material Brokerage | Buying Selling Scrap Scrap Substitutes . Our customers profit from the ability of TMS International's extensive worldwide purchasing offices to buy and sell scrap and scrap substitutes at competitive prices.

ball mill for ore raw material

Cost Effective Iron Raw Material Ball Mill. Ball mills for wet and dry grinding appliions Turnkey raw meal and cement plants including raw material handling storage This makes the civil engineering work more cost effective Vertical roller mills are suitable for plant capacities between 2 tph and 40 tph with product sizes ranging between 100 lt 10 181m and coarse products. ore raw material ...

Overview of the Steel and Iron Ore Market

Overview of the global steel and iron ore market 6 Production output trends 7 Consumption trends 9 Input raw material price trends 11 Steel price trends 14 Global steel trade statistics 15 China's steel and iron ore market 16 Overview of the Russian steel and iron ore market 21 Production output trends 22 Consumption trends 24

IRON, STEEL AND BASE METAL PRODUCTION IN MYANMAR

three small iron and steel mills operated as state enterprises, a modern copper hode production plant at a mine near Monywa and foundries attached to several state factories, the base metal casting industry is carried out in scores of small private workshops throughout the country. Stats released by the Ministry of Industry1 in 1999 showed a total of just over 600 private shops with a ...

MANDIRI | Grinding Media Chemical

Mineral processing typically is commenced with size reduction of raw material such as crushing and grinding. Grinding media usually contributes large proportion of mineral processing and in cement industry operating cost so the best strategy in sourcing and appliion of grinding media are paramount. Generally, grinding media product consists of forged steel grinding balls, cast iron grinding ...

Body and glaze preparation | SACMI

Correct preparation of raw materials is essential to achieving excellent, consistent results and requires the reliability, quality and knowhow gained through years of experience.

Beneficiation of Iron Ore

· Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation. All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 ...

MAGNETIC SEPARATORS

Chemicals Removal of iron from raw materials and waste fl uid. Casting and nonferrous Removal of iron from casting sand and chips. Sand and cement Removal of iron from raw materials and mixed machined parts. Feed and fertilizer Textile and fabric Sugar, salt and tobacco Removal of iron from raw materials. Separation on conveyor (dry) Separation by magnetic drum (dry) Separation by suspended ...

Latest Posts

- محجر تستخدم إلى حد ما في الصين

- مراحل سحق خام الحديد

- افضل منتجي الاسمنت الابيض في مصر

- هيونداي الحجر سعر كسارة الصين

- مصنع غسيل النحاس على نطاق صغير شيلي

- مصر الموردين كسارة حجر

- خام الحديد المطحنة المصنعة في حيدر أباد

- آلة غسيل الرمل بالجزائر

- معدات التعدين في بيرث

- الشركات المصنعة للالكسارة المتنقلة المتوسطة

- مجموعة من فارغة آلة محطم

- مصنع ريمون للمطاحن الجزائرية

- مطحنة للبيع في السعودية

- آلة بيع إعادة التدوير للبيع

- أسعار الذهب المستخدمة في العراق

- Gold Ore Grinding Machinery

- Crushing And Screening Machines Price

- Mobile Crusher Conveyor

- Stone Crushing Plants Spare Parts Manufacturers In South Venezuela

- Zimbabwe Original Mill Production Line

- Laboratory Planetary Ball Mill To Grinding Mineral Sample

- Wayneston Bears Crushed Garnet For Sale

- Jaw Crushers In Operation In Winnipeg

- Cement Mills Ahad

- Mobile Crushing And Screening Price

- Crusher Impact And Hammer

- Stone Crushing Cia

- Price List For Mobile Jaw Crusher Mc 120

- Mining Equipment For Sale In Turin Piemonte Italy

- Cedar Rapids 550 Cone Crusher