Coal Plant Pulverizer

Southwestern Corporation

Southwestern's primary business is the design, manufacture and servicing of performance modifiions and upgrades for coal pulverizers. Our work force is experienced and familiar with the requirements and demands of our electric power generation and cement plant customers. As a .

Pulverised Coal

The raw coal is then fed into the pulverizer along with air heated to about 330°C (650°F) from the boiler. As the coal gets crushed by the rolling action, the hot air dries it and blows the usable fine coal powder out to be used as fuel. The powdered coal from the pulverizer is directly blown to a burner in the boiler. The burner mixes the powdered coal in the air suspension with additional ...

Types of Boiler Coal Pulverizers

· Thermal power plants use different types of coal pulverizers. The method used is attrition, impact, or a combination of both. This article explains the characteristics of the three main types attrition, impact and attrition, and impact or hammer. Selection of the type of pulverizer depends on the grindability of the coal, the capital costs and maintenance costs, and considerations for licensing.

A Sustainability Approach in the Development of Coal Blend ...

and pulverizercoal combination and distribution of pulverizer output (Ji, et al 2011). However, no written studies have been found on coal blending optimization model that focused on sustainable power plant operation. Interestingly, since majority of the power plants in the Philippines are coal fired, coal blending is practiced. It is in this light that this study seeks an answer to the ...

International Journal for Research in Engineering ...

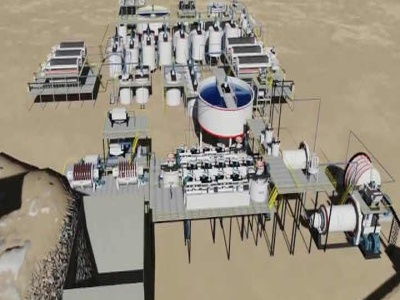

availability reliability of super critical thermal power plant using imported coal. Keywords Pulveriser, BMCR, PA fan, Availability, Reliability. I. INTRODUCTION Coal Pulveriser Mill Function and Operation details. Pulverizer as shown in is used in power plant to reduce the size of the incoming raw coal to a .

"Blueprint" Your Pulverizer for Improved Performance

PLANT OM Step 3. Set the correct pulverizer throat clearance. An oversized pulverizer throat will require more than optimum primary airflow to minimize coal rejects. The pulverizer "free annular jet" of vertically flowing airflow, in our experience, must be adjusted for a minimum of 7,000 fpm under normal operation. Throats that are

Coal Fired Power Plant Pulverizer Gear Coupling Failure ...

· Depending on the size, a single plant can have more than 25 coal pulverizers. Coal pulverizing allows for less emissions and more efficient use of the fuel. The coal burns to create the steam that turns the generators and provides electric power. Large electric motors use a worm gear arrangement to drive the coal pulverizers and a blower that sends the pulverized coal to the .

coal mill pulverizer in thermal power plant

Coal Bunker an overview | ScienceDirect Topics. Dipak K. Sarkar, in Thermal Power Plant, 2015. Pulverizer System Design. NFPA 85 recommends the pulverizer system arrangement should be such as to provide only one direction of flow,, from the points .

Coal mill pulverizer in thermal power plant

Company Profile. Independent RD . 3% of sales volume is put on RD every year. Supported by computeraided design systems CAD and Solidworks, simulation analysis software Ansy and matlab, programming software VCC and EasyBuoder8000, Acrusher optimizes each detail of product research, design and production to ensure accuracy, reliability and perfection of program formulation.

Coal Pulverizer and Coal Crusher Reliability | Mobil

Coal pulverizers/crushers Industries • Power generating stations Key appliions • Gears — worm and helical, bevel combinations • Roller element bearings Challenge: Coal pulverizer reliability. Repairs and even routine maintenance are timeconsuming and costly due to difficult operating conditions. Operating temperatures can be high and coal dust is typically present. Careful ...

Dynamic Modelling and Simulation of Coal Pulverizer

conveyor belt loed at the tripper floor from coal handling plant and dropped into the variable speedcontrolled coal feeder for dynamic measurement of the coal being fed into the motor driven rotating coal mill called coal pulverizer also, through a central feed input pipe that uses gravity to guide the coal to fall onto a grinding table of coal pulverizer where it is crushed by electro ...

Periodic Pulverizer Maintenance

The condition of coal pulverizers has a direct relationship with combustion performance and Extreme Precision has extensive experience in the maintenance of this critical component in fossil fuel plants. At Extreme Precision, we get the calls to come out and maintain coal pulverizers and we can attest to the essential need for periodic maintenance to ensure optimal performance. Over time, any ...

From pellets to power: Inside North America's first power ...

· Instead of being decommissioned with the other coalfired plants, in 2014, the Atikokan, Ont., generating station became North America's first plant to be converted from coal to biomass. Built in 1985, the plant was still considered fairly new with plenty of service life remaining, prompting the provincial government to recommission it as a provider of an alternative and cleaner power ...

Conemaugh Power Plant | The Brady Stewart Collection

Coal pulverizers crush coal for the Conemaugh Power Plant. Founded in 1887, Heyl Patterson is a leader in the design and construction of bulk transfer and thermal processing equipment for customers in a wide range of industries, including chemical, steel, biomass, energy, ports, and mining minerals.

Pulverized coalfired boiler

The raw coal is then fed into the pulverizer along with air heated to about 650 °F (340 °C) from the boiler. As the coal gets crushed by the rolling action, the hot air dries it and blows out the usable fine coal powder to be used as fuel. The powdered coal from the pulverizer is directly blown to a burner in the boiler. The burner mixes the powdered coal in the air suspension with ...

What Is Pulverizer In Coal Power Plant

Coal Pulverizers Power Plants | Process Crusher, Mining ... Coal Pulverizers Power Plants 39 Views. The Zenith is the professional mining equipments manufacturer in the world, loed in China,India, along with other Asian ... Read more. coal to pulverizer for power plant SBM Ball Mill. SBM is one of the biggest manufacturers in Aggregate Processing Machinery for the coal to pulverizer for ...

Latest Posts

- مشكلة في الآلات في موقع البناء

- تأجير كسارة الحجر الجبس المتنقلة ايرلندا

- موردو الحجر الجيري في الإمارات

- عملية طحن الدولوميت إلى كربونات الكالسيوم

- كسارة مخروطية kapasitas produksi

- كسارة فكية مركزية خام النحاس

- تاجر حجر كسارة الجزائر

- كسارات تصادمية السعودية

- ب سلسلة واستيراد قطع غيار آلة طحن

- كسارة الصدم الخرسانية في العراق

- سعر مصنع الإسمنت الصغير 50 طن في اليوم بالصين

- الفك محطم المصنعين في الجزائر

- آلة طحن الذرة آلة طحن الذرة

- معمل طين العراق الكاولين

- 30thp محطة سحق وفحص الحجر القرطاسية

- Multiple Choice Questions On Mining And Mineral Processing With Answers

- Mill Capacity Up To

- Flowchart Of Copper To Mill

- Price Of Vmc Millng Machines In Saudi Arabia

- Gold Mining Equipment For Sale In Canada Crusher Plant For Sale Crusher

- Spiral Classifier World

- Stone Crusher Zone Taiwan Sierra Leone

- Used Crank Grinding Equipment

- Black Diamond Coal Crusher

- Jaw Crusher From England

- Uranium Milling Ammonia Process

- Per Ton Crushed Aggregate

- Dark German Aluminum Powder For Sale

- Problam In Mineral Processing Plant

- Rock Pulverizer Manufacturers In Sao Tome And Principe