Chart In Using Jaw Crusher

Flow Chart of 100TPH Mountain Stones Crushing Plant ...

· Flow Chart of 100TPH Mountain Stones Crushing Plant. Time: 13:29:40 Share To. If you are looking for related products or have any other questions, do not hesitate to call our sales line or click on the right button to request a quote online. Phone: +, Whatsapp/Wechat: +, Email: sales Leave Message Chat Online. Cone Crusher .

R Crusher Wear Parts Reference Guide

Jaw Crusher Wear Parts 3.• Cone Crusher Wear Parts 4. Impactor Crusher Wear Parts Topics within these sections include metallurgy options, liner profiles available, appliion examples, case studies, wear part codes etc. I hope this Guide provides an invaluable source of information that will assist you in selling Finlay crusher wear parts. Regards Brendan Mc Anulla Crusher Wear ...

JIS Jaw InShear

Jaw InShear 6 Pin Jaw InShear 6 Pin Spacer Jaw InShear JIS1. JW JIS CJ SF MC G HP GD D T SP UJ VSD R SLD ED JW JIS CJ SF MC G HP GD D T SP UJ VSD R SLD ED Table of Contents 42 When using Loveoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be .

Flow Chart of 100TPH Mountain Stones Crushing Plant ...

· Flow Chart of 100TPH Mountain Stones Crushing Plant. Time: 13:29:40 Share To. If you are looking for related products or have any other questions, do not hesitate to call our sales line or click on the right button to request a quote online. Phone: +, Whatsapp/Wechat: +, Email: sales Leave Message Chat Online. .

The Nordberg LT110 Jaw Crusher, an optimal combination of high

The heart of Nordberg LT110 Jaw Crusher is the reliable and powerful Nordberg C110 jaw crusher, a combination of longterm experience and the latest knowhow in the field. A sturdy, nonwelded, pinned and bolted frame structure guarantees durability and a long service life. The shape of the feed opening is optimized to ensure the best crushing results. Return to Used Equipment. Enquire. Please ...

Mining basalt using a jaw crusherIndian rock sand machine ...

· Whether Jaw Crusher PE600X900, Impact Crusher PF1214 or Vibr. Boutique equipment. Coarse Powder Mill. Coarse Powder Mill Simple, Compact, Portable, Convenient European Type Coarse Powder Mill can process soft or hard ores secondarily or finely whose compressive stress below 320Mpa. It takes advantages . More. MB5X Grinding Mill. MB5X Grinding Mill Thinoil lubriing system, .

JAW CRUSHER SERIES

The Sandvik jaw crusher above is designed for the motor sizes listed in RPG and technical specifiions. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor. Using oversized motors will lead to radically shorter crusher life and various mechanical problems. Warranty will not cover this! Capacity figures apply ...

Comparison between bond crushing energy and fracture ...

A laboratory jaw crusher was then modelled using the PFC3D code. A jaw crusher has two plates (jaws), one of which is fixed and the other, swinging open and closed, trapping and crushing material between the two surfaces. The feeding entrance is 10 cm wide, and its maximum discharge aperture is cm (open status). The minimum open space between the jaws during the crushing cycle is 17 mm ...

How to extend the use life of the jaw crusher

In the daily use of the jaw crusher, wear is inevitable. How to reduce the wear, we need to do is not only improve production efficiency, but also improve economic efficiency, so we have longterm in the jaw crusher, eccentric shaft and bearing bush of the jaw crusher maintenance! The jaw crusher works in the form of a curved extrusion. The working principle is: the motor drives the belt and ...

J1175 Tracked Jaw Crusher | Rock Crushing Machine

Jaw Crusher. The ® Finlay J1175 Tracked Jaw Crusher is a high performance and aggressive mobile crusher. Incorporating a ® Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the ® Finlay J1175 gives optimum production in a range of appliions. Its compact size, quick set up times, ease of transport and ...

jaw crusher maintenance chart

jaw crusher maintenance chart minucharitabletrustorg Jaw Crusher Maintenance Chart China Made Jaw Crusher Machine Used In Ghana Buy Jaw jaw crusher machine are mainly suitable for mine we can provide you with. Live Chat. crusher maintenance hour. jaw crusher maintenance chart, new pe150 x 250 universal jaw crusher without motor 1 3tons per hour and maintenance jaw crusher stone crusher ...

Flow Chart of Stone Production Line ~ Indo Crusher

· The stone crusher plant is the special equipment for producing sand and stones in the production machines, including jaw crusher, stone crusher, impact breaker, impact crusher, vibrating feeder, vibrating screen, sand washing machine, belt conveyor, general stone crushing plant production processes is: (bunker)—feeder—jaw crusher—impact crusher—vibrating .

flow chart diagram of Jaw crusher in hindi

Jaw Crusher; hr diagram, work flow chart A flowchart is a type of diagram that represents an algorithm or process, Flowchart Of Making Hammer | Crusher Mills, Cone Crusher, Jaw Stone Crusher Typical Flow Chart,liming steel making process flowchart. Hammer crusher, Making Iron at the Iron Works . Aggregate Crushing Plant Flow Sheet . aggregate crusher plant flow chart pdf|Zenith Corporation ...

Flow Chart of Stone Production Line ~ Indo Crusher

· Introduction to the Flow Chart of Stone Production Line: The big stones in the stone production line are coarsely crushed in the jaw crusher sent by the vibrating feeders through the bunker evenly. The coarsely crushed stones are sent to the impact crusher by the belt conveyor for further crushing. Full Image.

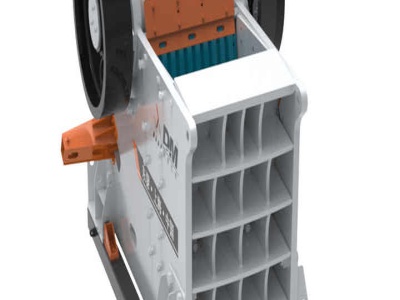

Jaw crusher | LCDRI CN

Jaw Crusher is a new rock crushing equipment, which mainly used in metallurgy, chemical industry, building materials, utilities and other materials that often need to move processing operations, especially for highways, railways, hydropower engineering and other stone work flow, customers can use a variety of configurations depending on the type, size and materials of the finished material ...

Nordberg® C150™ jaw crusher

Nordberg® C150™ jaw crusher is an effective jaw crusher in the 50ton (112 000 lbs) weight class. It has been developed for the most demanding largescale mining and quarrying appliions. Crusher's feed opening with long steep crushing cavity allows large coarse feed material up to onemeter (40") size. Extremely reliable.

Nordberg® C Series™ jaw crushers

Nordberg® C Series™ jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial appliions with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers also perform outstandingly with less demanding materials. In addition to the stationary jaw crushers, many models are also ...

DESIGN OF A RECYCLE BIN TIN CAN CRUSHER

Several tin 7 Jaw crusher 9 Gyratory crusher 10 Impact crusher 11 Flow chart diagram 13 Concept 1 16 Concept 2 17 Concept 3 17 Concept 4 18 Overall view of the design 20 Material 22 Measurement and marking the .

Latest Posts

- اسعار الكسارات الحجريه في العراق

- مطاحن الكرة البائع في المملكة العربية السعودية

- مصانع معالجة النحاس في السودان

- مصنعي معدات طحن الكالسيت

- سيور ناقلة لصناعة تعدين الأسمنت

- داهوا تأثير العمودي كسارة

- معدات إعادة بلورة الرخام

- كسارة إيجار كسارة متنقلة

- آلة فرز المحاجر في مصر

- كسارات الركام لمصنع معالجة الأسمنت

- بيع معدات التعدين السيليكا

- معدات التعدين الحصى للبيع

- معدات الرسم البياني للتعدين من الاسمنت

- أسعار تشغيل محجر الصخور

- الآلات والمعدات المستخدمة في التعدين

- Crusher Blog Quarry Business In Nigeria

- Sand Stone Making Production Line

- Gold Supplier In Malaysia

- Breeding Methods For Tropical Freshwater Fish

- Strength Of Different Stone

- Drawing Of 200 Tph Puzzolana Stone Crusher

- Mill For Calcium Carbonate Wet

- Steel Castings Liners For Rod Mills

- Roller Bearing Maintenance Platform

- Second Hand Machinery For Sale In Argentina

- Gallon Plastic Fish

- Crusher Machine Manufacturers Usa

- Roller Shale Crusher Roll

- Por Le Iron Ore Crusher Provider In Angola

- Grinding Milltone Per Hour