How To Build A Jaw Crusher Model

Jaw Crushers | Heavy Duty | Finlay

The ® Finlay J1170 (direct drive) tracked jaw crusher features a heavy duty variable speed VGF and integrated prescreen giving excellent production throughput in quarrying, mining, demolition and recycling appliions. The main conveyor has an excellent discharge height and increased clearance at the bottom of the chamber for rebar discharge due to the hydraulic raise/lower facility ...

Build Jaw Crusher

Build A Jaw Rock Crusher. Build a simple rock crusher GPEX. just start collecting some scrap steel and build your self a small jaw crusher the concept and build is very easy heres one i built to crush rock to 18 to free the placer nuggets trapped in the solid rock. If I Wanted To Build A Jaw Crusher Page 4. Nov 03, 2012 I too grew up with a gravel operation. The use of a jaw was to ...

Lokomo's jaw crusher returned home after more than 90 ...

· Crusher technology from 1858. Keijo Viilo, Research Director at Metso Minerals, knows well the origins of the technology employed in the Lokomo A2 jaw crusher. "The crusher is known for its double toggle technology, developed and patented by the American Eli Whitney Blake, working in New Haven, won a twomile road contract from the city and thought that it must be possible .

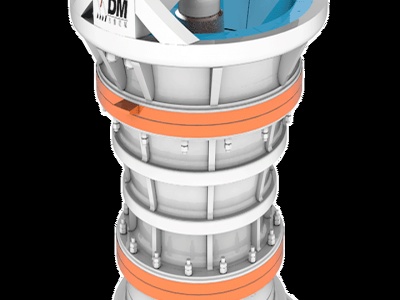

RC46 Gas Powered Multi Stage Rock Crusher

The Multi Stage Rock Crusher, three stage model, includes a jaw crusher and a double roller mill is shown below. To begin, the unit processes 4″x6″ rocks through the Jaw Crusher (on top). Next the crushed rock falls down into the Double Roller Mill (on bottom). Finally, an ultra fine powder of 60110 mesh comes out the bottom of the roller mill. As a result, a single pass, through this ...

mobile jaw crusher models

mobile jaw crusher models. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment. which can crush all kinds of metal and non ...

Stone Crushers Machine | Top 10 Manufacturer In China

· Stone crusher commonly used models are PE series coarse jaw crusher, PEX series fine jaw crusher, impact crusher, cone crusher, impact crusher, roll crusher, and so on. FUREIN produces all kinds of stone crusher models, which can be designed and matched according to your capacity to provide better solution and services. Various types of stone crushers can meet your different needs. .

What Are Crushers? | Omnia Machinery

· Jaw crushers are the archetypal crusher used for the dismantling of rock and stone; with a quarry jaw crusher, you are able to crush all kinds of materials to various sizes depending on your requirements. Explanatory by name, jaw crushers reduce materials between a fixed and a moving jaw. The moving jaw puts pressure on the material and pushes it against the stationary plate, the rocks .

Crush, Screen and Track

The Rebel Crusher fits into a 40' High Cube container for ocean transport. Crushing asphalt with the Rebel Crusher. OUR GOAL: To DESIGN and BUILD the PERFECT ROCK CRUSHING and SCREENING SYSTEM. Built as a Jaw Crusher or an Impact Crusher, the Rebel Crusher is like no other! The BEST Rock Crusher, Limestone Crusher, Concrete Crusher, Stone ...

Jaw Crusher For Sale

Jaw crusher for sale is mainly used for the primary crushing of various of ores and large single jaw crusher machine can produce up to 1000 tons per hour. The raw materials it include quartz stone, bluestone, river pebbles, pebbles, limestone, iron ore, and so, it is widely used in mining, smelting, building materials, highway, railway, water conservancy ...

Jaw crusher,Jaw crusher for sale,Jaw crusher price,Jaw ...

Jaw Crusher. The jaw crusher is widely used in mining, building materials, chemical industry, metallurgy and so on. It is suitable for primary and secondary crushing of all kinds of minerals and rocks with compressive strength less than 320 MPa,such as iron ore, copper ore, gold ore, manganese ore, river stone, gravel, granite, basalt, minerals, quartz, diabase, etc.

Jaw Crusher, Jaw Crusher Manufacturer, Jaw Crusher for ...

Jaw crusher has serveral series such as HJ series Jaw Crusher, PE series Jaw Crusher and PEW series Jaw Crusher. It is composed of the dynamic and static two crushing chamber jaw plates, simulate the movement of animals to complete material crushing operations. Jaw crusher can process a maximum compressive strength of the material tup to 320Mpa, it is widely used in mining, smelting, .

Jaw Crusher, Jaw Crusher Manufacturer, Jaw Crusher for ...

Jaw crusher has serveral series such as HJ series Jaw Crusher, PE series Jaw Crusher and PEW series Jaw Crusher. It is composed of the dynamic and static two crushing chamber jaw plates, simulate the movement of animals to complete material crushing operations. Jaw crusher can process a maximum compressive strength of the material tup to 320Mpa, it is widely used in mining, smelting, building ...

Crushing

· CRUSHERS Power and production meet in Lippmann design and unparalleled features optimize crushingoperation, bringing the highest production values across allindustries, and around the world. Lippmann combinesheavy duty build design for longevity and industry leadinginnovative design features for consistent optimum performanceand return on investment.

Jaw crusher

· JAW CRUSHER. 2. • Crusher • Crusher is size reduction equipment A crusher is a machine designed to reduce large rocks into smaller, more manageable particles. • Crusher is a machine which is used to crush heavy size particle into small size, also it's a primary size reducer. • Crusher are low speed machine for coarse reduction of ...

How to Repair Roller | Crusher Blog

· Roll crusher for primary crushing of materials is that it in some stone production line is also very widely used for cement, metallurgy, chemicals, electricity, coal, building materials, refractories and other industrial sectors broken, the higher hardness materials. Normally, under the roll crusher roller wear, the roller surface is not cylindrical, forming two big middle.

Jaw Crusher

Jaw Crusher Components: There are several main parts of jaw crusher: frame, jaw plate and side guard plate, and transmission part. The frame is a fourwalled rigid frame, and it is used to hold the eccentric shaft and stand the reactive force of crushed material. So, the frame needs sufficient strength and rigidity. It is usually made of cast ...

Ansys Tools Enabled Metso to Design a Higher Capacity Jaw ...

Metso jaw crushers reduce large rocks into smaller rocks or gravel by holding material between two solid surfaces and exerting enormous force — up to several meganewtons — to fracture the material. Metso engineers set out to substantially increase the work capacity of a new jaw crusher model while maintaining the same weight as the previous generation, which is crucial because jaw crushers ...

Simple Jaw Crusher | 3D CAD Model Library | GrabCAD

· Simply drawing of jaw crusher to help building chassis and arranging layout in stone crusher plant, plus some specifiion.

A fundamental model of an industrialscale jaw crusher ...

· The model is based on previous knowledge from studies of cone crushers applied to jaw crushers. The model has been tested with an industrialscale crusher geometry, to which the simulation results presented in this paper apply. A framework has been developed for modularbased fundamental modelling, where each module has been developed separately and tested before being used in a full ...

build a jaw crusher tunisia

plans to build a jaw crusher tunisia. Plans are drawn by a professional To Build A Jaw Crusher Tunisiadiy jaw crusher plans plans to build a jaw crusher tunisia Nov 02 2008 Re if i wanted to build a jaw crusher I have looked at several on youtube most look like they have a flywheel now these are small and old some are shown running off a steam tractor and a belt do Service ...

Jaw Crusher Models Mph

Jaw crushers Metso. The product family consist of several different size jaw crusher models that are engineered to deliver maximum productivity at the lowest operating costs Nordberg C Series jaw crushers have proven to be reliable and productive in thousands of mining quarrying recycling and industrial appliions with up to 11000 jaw crusher

Latest Posts

- الرمال السعري تأثير محطم

- 100 150 الفك محطم المصنعين

- مصنع خلط صغير مصر مستعمل للبيع

- مطحنة الكرة وإنتاج الزنك

- شراء آلة استخراج للحجر الجيري

- مكائن تعدين الذهب في السعودية

- خزان تحريك معدات التعدين الذهب ل zimbabwe

- كسارة الفك للبيع بي ام دبليو

- 5 مطحنة لالبنتونيت في مصر

- آلات تكسير الجير الإيطالي

- مصر مخروط مصر مصر في مصر

- سعر كسارة الفك الجبسية

- سحق الحصى في مصر

- سعر الحجر الجيري المسحوق للبيع في السلطة الفلسطينية

- أنواع آلات الطحن

- Ceramic Crushed Ceramic Crushed Manufacturers For Sale

- Digunakan Impactt Crusher Untuk Dijual

- Used Slag Grinder Machines Germany

- Hydrocyclone Machineries China

- Stone Crushing Plant Keesara Crusher

- Bearings For Renk Ag Cement Ball Mill Gearbox

- Vsi Crusher Semi Automatic Grease Systm

- Gold Cyanide Processing Equipment

- Mining Scool Of Ghana

- Mini Quarry Machine Maker

- Mill Lead O Ide Production

- Small 50tpd Cement Plant Manufacturing Libya

- Blackrock Iron Ore Project Mining Canada

- Air Mikro Grinder Rpm

- New Type Cone Crusher For Yemen