Gyratory Crusher Mani Shaft

Gyratory crusher main shaft

Gyratory crusher main shaft Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Gyratory crusher main shaft, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply standalone crushers ...

Mining NonFerrous

Gyratory Crushers. MORE IMAGES. DOWNLOAD BROCHURE . CITIC HIC manufacture a range of Primary Gyratory Crushers to suit both the Mining and Aggregate Industries with an installed based operating since 1997. AJ JAW Crusher (AUTO JAW) DOWNLOAD BROCHURE. CITIC HIC has developed single toggle AUTO JAW Crushers range to suit both the Mining and Aggregate .

CC cone crusher

Product. Our products cover crusher, grinding mill, screen, feeder, classifier, conveyor belt and others. Core products include GC gyratory crusher, JC jaw crusher, CC hydraulic cone crusher, MC hydraulic cone crusher, HS impact crusher, VS verticalshaft impact crusher, YKR/ZKR vibrating screen, HPF grizzly feeder, MP/MK mobile crushing screening plant, and CLTC drywet dust removal devices.

HGT Hydraulic Gyratory Crusher – Stone Crushers Grinding ...

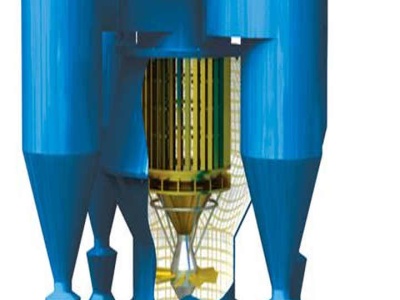

HGT Hydraulic Gyratory Crusher consists of beam, upper frame, middle frame, lower frame, moving cone, eccentric sleeve, transmission part and hydraulic cylinder part. Horizontal shaft driven by motor rotates constantly. Then horizontal axis makes eccentric sleeve rotate by gear, after that eccentric sleeve will drive the moving cone to swing circularly, so as to realize crushing process.

"Let's not make this more complied than it really is

Primary Gyratory Crusher Basic Gyratory Head and mantle Hydroset System Concave Liners Spherical Spider Eccentric causes the main Bushing shaft with the head and mantle attached to move back and forth towards stationary concave liners. Rock is compressed/crushed between mantle and concaves. 2/29/2016 14 Gradation is controlled by adjusting the spacing between the mantle and the concaves at ...

CG800i Gyratory Crushers — SRP

A robustly designed onepiece main shaft and reinforced shells are made for tough use. The onepiece spherical spider bearing offers at least 5 times longer wear life than than previous Sandvik crushers. High reduction, great capacity. Welldesigned spider bearing built from strong materials make a fulcrum point that ensures a constant eccentric throw, guaranteeing up to 90% of feed opening ...

Midsouth Machine Service

Refurbished HP200 Crusher Complete with New Main Shaft. HP300 Cone Crusher Ready to Go Back to Work. TECHNICAL SELF HELP. Crusher Lifting Best Practices. Daily Checks Maintenance Nordberg CJaw Crushers . Daily Checks Maintenance HP300 through HP500. Daily Maintenance Checks for Symons Style Crushers. General Daily Inspection Guidelines for Sandvik Style Crushers. .

Crushing | Resources Unity

The Prime series Primary Gyratory Crusher is equipped with a heavyduty spider assembly along with 1 piece main shaft / head assembly to accommodate the toughest of appliions and easy maintenance procedures resulting in less downtime. Every component of the Prime Primary Gyratory Crusher is manufactured within our own factory ensuring control over product design, quality, manufacture and ...

Crusher Bearings Technical White Paper | Timken

Cone Crushers Cone or gyratory crushers use a variety of specialized bearings speciically designed for each model. Like jaw crushers, these machines – common in primary, secondary and tertiary crushing circuits – also operate at moderate speeds under heavy loads and experience signiicant load spikes. In a standard cone crusher, the main shaft is housed in a frame attached to a mantle. A ...

Gyratory Crusher Pinion Shaft Housing

Gyratory Crusher Pinion Shaft Housing Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Gyratory Crusher Pinion Shaft Housing, quarry, aggregate, and different kinds of minerals. We can provide you the complete stone crushing and beneficiation also supply stand ...

gyratory crusher shaft

gyratory crusher mani shaft crusher units .... Fixing the type plate in the maintenance shaft. 4 ... forces exerted on the plant and cone or ..... Danger. Ne jamais pénétrer dans le puits de ... Get Price Here ! Advanced development of jaw gyratory crushers ... The main shaft of the jaw crusher is radially guided in the rolling contact bushing in the upper main shaft ...

Choosing the Right Rock Crushing Equipment

· Gyratory Crusher. A gyratory crusher consists of a concave surface and a conical head constructed from heavy steel casting. It works by using a mantle that gyrates within a concave bowl. This rock crushing equipment uses compressive force to fracture the rock and this happens when the mantle makes contact with the bowl during gyration.

Crushers for Mining

Gyratory Crusher Parts (8) Hammer Mill / Impact Crusher (21) HPGR / Roll Crusher (3) Jaw Crusher (8) Jaw Crusher Parts (4) Ring Puck (4) Shorthead (9) Sizer (4) Rock Breaker (2) Standard (8) Hydrocone / Gyracone (3) Lab Crusher (3) VSI Vertical Shaft Impactor (4) Cage Mill / Pulverizer (2) Lab / Pilot Hammermill (8) Other (6) Miscellaneous Parts (2) Manufacturer. Allis Chalmers (13) AMCAST ...

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER

Jaw crusher, Gyratory crusher, Impact Crushers, etc. b) Secondary crusher The crushed rocks from primary crusher are sent to these secondary crushers for further size reduction. Example:reduction gyratory crusher, Cone crusher, disk crushers etc. c) Fine crushers Fine crushers have relatively small openings and are used to crush the feed material into more uniform and finer product. Example ...

Midsouth Machine Service

Refurbished HP200 Crusher Complete with New Main Shaft. HP300 Cone Crusher Ready to Go Back to Work. TECHNICAL SELF HELP. Crusher Lifting Best Practices. Daily Checks Maintenance Nordberg CJaw Crushers . Daily Checks Maintenance HP300 through HP500. Daily Maintenance Checks for Symons Style Crushers. General Daily Inspection Guidelines for Sandvik Style Crushers. General Routine Crusher ...

The Installation Points of 5 Major Components of Gyratory ...

· The installation of the transmission part is related to the operation of the gyratory crusher, so when installing, we must pay attention to the center of the two copper sleeve to always maintain at the same level, without deviation, and the radial clearance between the copper sleeve and the shaft should also be strictly in accordance with the instructions of the equipment manual, and keep ...

Gyratory Crusher l Introduce, Working Principle

Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusher. The gyratory crushing equipment has a bright future in the mineral processing market. Its working part is a highspeed rotary crushing roller, which is coupled with a pair of curved crushing plates arranged symmetrically on the left and the right to form two optimal crushing cavities for the pliers ...

SMAN Cone Crusher – Manufacture of Crushing Screening ...

The Cone crusher is operates via electric motor that drives a horizontal shaft pinion bevel gear further rotating a crown bevel gear mounted on an vertical eccentric sleeve creating a gyratory motion that affects the centre axle fitted inside the sleeve creating a compression crushing action between the Mantle concave section.

Construction, Working and Maintenance of Crushers for ...

Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the workhorse of the hard rock crushing industry. A gyratory ...

(PDF) Gyratory Crushers TC, NT and TS model crushers ...

Gyratory Crushers TC, NT and TS model crushers 2 FLSmidth's FullerTraylor® Crushers Our experience with Mining Industries (Minerals, Cement, and Aggregate) has resulted in a complete line of Gyratory Crushers to satisfy the requirements of a wide variety of our customers' appliions.

Choosing the Right Rock Crushing Equipment

· Gyratory Crusher. A gyratory crusher consists of a concave surface and a conical head constructed from heavy steel casting. It works by using a mantle that gyrates within a concave bowl. This rock crushing equipment uses compressive force to fracture the rock and this happens when the mantle makes contact with the bowl during gyration. Gyratory crushers are often built into a cavity in the ...

USA

Securing means for crusher head to gyratory shaft, including an internally threaded nut shrink fitted to main shaft of crusher EPA1 (en) : Method of mounting stones in disc or attrition mills. USA (en) : Gyratory or cone crusher with a crusher cone including a core and a mantle USA (en) : Severable head nut for gyratory crusher USA (en ...

Midsouth Machine Service

Midsouth Machine Service Company hosted a three day training course for cone crusher repair and rebuild, which was conducted by Excel Foundry Machine in Pekin, Illinois. Excel is a manufacturer of premium high performance replacement parts for the mining and aggregate industries and a .

Latest Posts

- معدات مطحنة الكرة المستخدمة في مصر

- التكنولوجيا العالية المهنية غرامة سعر طاحونة الحصى

- غرامة كسارة الرمال تشيناي

- الأنتيمون المصانع

- صيانة ناقل لخام الحديد

- بيع المطاحن في اليمن

- مورد كسارة

- كسارة المطرقة مصر للبيع

- مطحنة qv مصر

- طحن الخبث في مطحنة الكرة

- كسارة الفك الناس 1000 1200 السعر

- إعداد مصنع تعدين الحجر الجيري

- سعر معدات كسارة الحجارة في الولايات المتحدة الأمريكية

- كسارة تصادمية maxcap

- طاولة الحجر الجيري مطحنة الأسطوانة العمودية

- Coal Pulverizers Used In Cement Plants

- Neutrik Por Le Grinding Machine

- Requirements For Quarry Permit From Denr

- Ball Mill Grinding Clinker

- Diamond Grinder Rental Edmond Ok

- What Is The Ball Mill Plant Used For

- Spesifikasi Motor Mesin Frais Milling

- Types Of Coals And Uses

- Equipment For Processing Gold

- Buy Using Mobile Crushing South Africa

- Stone Crusher For Sale South Africa 600

- Steel Plate Jaw Crusher

- South Africa Pearl Mill Machine Manufacturer Mrchadvani

- Rock Crushing And Screening Equipment Manufacture Dubai

- Italy Li Ne Mine