Hematite To Iron Process

Hematite – To Fake or Not to Fake | Appealing Environments

· Hematite is often referred to as a bloodstream purifier. When you polish or drill into this stone, it appears to bleed due to the high concentration of Iron Ore. This stone energizes the entire body by improving circulation and the flow of oxygen to all cells. Hematite is also a protective stone and enhances optimism, courage and willpower.

Hematite Iron Ore Processing Plant

Hematite Iron Ore Processing Plant. Description arrium previously onesteel initiated a desktop study into the performance of its hematite ore beneficiation plant in early 2010 the beneficiation plant utilises jig concentrators and spirals to upgrade lowgrade hematite recovered during mining at the iron duke id mine site loed 60 km southwest of whyalla.

hematite to iron process

Hematite: A primary ore of iron and a pigment mineralAlthough magnetite contains a higher percentage of iron and is easier to process, hematite is the leading ore because it .

How Is Iron Extracted From the Earth?

· Iron ores in the form of hematite (ferrous oxide) and magnetite are removed from the earth through mining. The use of heavy mining equipment is necessary to dig out large pits in an area with a large deposit of iron ore; however, because iron does not occur naturally, it is necessary to use a blast furnace to separate or refine iron from the other substances in the iron ore.

Re: How is Hematite mined?

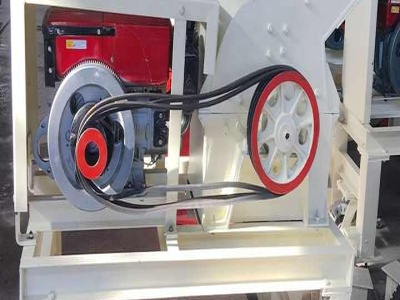

· The ratio of mineral to rock can be quite large up to to 1 for hematite. The material is stored in a covered building after being reduced to no greater than 10 inches in diameter in a primary crusher. The material is about 35% iron and is processed into pellets. The next step in the process .

a new method for processing iron ore hematite

· Processing And Recovery Methods Hematite Iron Ore. Processing And Recovery Methods Hematite Iron Ore. Hematite iron ore recovery rates. There are forty years of manufacturing history, with three major production bases,over 160 senior R D engineers and 600+ large and medium sized digital processing equipment, The first line technicians and professional after sales service .

Process for Manufacturing of Iron Carbide – IspatGuru

· The three main process steps of the process (Fig 1) include (i) heating of iron ore to around 700 deg C, (ii) contacting the hot iron ore with pressurized H2 and CH4 gas mixture at a temperature of around 600 deg C and an absolute pressure of around kg/sq cm in a fluidizedbed reactor for conversion of iron oxide to iron carbide with strong reducing gases, and (iii) cooling the .

Re: How is Hematite mined?

· The ratio of mineral to rock can be quite large up to to 1 for hematite. The material is stored in a covered building after being reduced to no greater than 10 inches in diameter in a primary crusher. The material is about 35% iron and is processed .

Iron Ore Processing

Iron Ore Processing 500. 2 Generally, the beneficiation of high/medium grade hematite iron ores in India includes dry circuit covering crushing, screening or wet circuit consisting of crushing, scrubbing, washing and classifiion [34]. This kind of ...

Mineralogy of Iron Ores of Different Alumina Levels from ...

the sinter. In the sintering process, the iron ore corresponds to the mixture of hematite, goethite and other gangue mineral typologies. However the goethite and gangue contents are relatively lower than the hematite, but the goethite + gangue to hematite ratio influences the reactivity during sintering. The minerals association in iron

USA

materials Substances description 18 US195842A Process for the manufacture of hematite cast iron Expired Lifetime USA ( en ) .

How is Iron Refined from Ore? (with pictures)

Although iron does not occur in its pure form in nature, some kinds of ore contain up to 70% iron atoms. Iron ore consists of oxygen and iron atoms bonded together into molecules. To create pure iron, one must deoxygenate the ore, leaving only iron atoms behind, which is the essence of the refining process.

How to Smelt Iron: The 6 Steps to Iron Smelting | The ...

What is iron ore? Iron ores are rocks and minerals rich in iron oxide that can produce metallic iron when smelted. Due to the nature of the iron oxide present in iron ore, they can range in color from dark grey to a deep red. The iron in such ores is commonly found in the form of magnetite, hematite, goethite, limonite, and siderite.

Hematite, the Shapeshifting Mineral Used From the Stone ...

· How Hematite Was Formed. Back when Earth was covered in primordial oceans about billion years ago, there was naturally an abundance of iron in the early aquatic plant life that could process sunlight and undergo photosynthesis started forming, the .

Formation of iron hydroxysulphate phases in the hematite ...

· Thus, the present work discusses the results of an investigation on hematite precipitation in a Fe 3+Zn 2+SO 4 2− –H 2 O system, which focused on the effects of the process parameters of temperature, time, initial ferric concentration, initial Zn 2+ concentration and amount of hematite seed on the extent of iron precipitation, and the transformation of metastable hydronium jarosite and ...

USA

materials Substances description 18 US195842A Process for the manufacture of hematite cast iron Expired Lifetime USA ( en ) Manufacture of iron .

Iron production in Ptolemaic Egypt: From the Abu Gerida ...

· Evidence of ancient iron manufacture in Egypt is to be found in the burnt plant remains, slag fragments, and a furnacelike structure discovered in the Hamama workshop in the Eastern Desert of Egypt. The iron ore required for iron production was delivered from the nearby specular hematite mines of the Abu Gerida area.

PROCESS FOR PRODUCING IRON POWDER FROM HEMATITE .

A process for producing iron powder which comprises passing a finely divided natural hematite ore through a high intensity wet magnetic separator to remove silica and other acid insoluble impurities, treating the purified finely divided hematite with a reducing agent at reducing temperatures below the melting point of iron and collecting the substantially pure iron produce obtained.

Induration Process of Pellets Prepared from Mixed ...

To explore the possibility of successfully processing iron ore pellets with a high content of hematite, thermogravimetric tests were performed to study the induration process of pellets composed of a mixture of iron ore concentrates (magnetite and 35% wt of hematite). Thermogravimetric tests were performed

Iron precipitation and associated metal loss from ...

To address the issue, simulated process solutions were used to study the effect of process parameters and their relative importance on batch precipitation conditions with the aim of obtaining a stable iron oxide phase hematite, while minimising associated metal loss to the precipitation product. It was found that the factors: initial ...

The Latest Developments in Iron Ore Processing

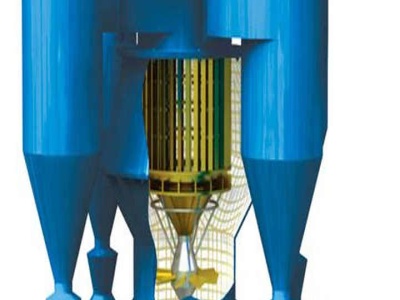

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones – diameter –Operating capacity of 600800t/h –Efficient separation at SG's as high as /cm3 Dense Media Separation on Iron Ore •

Bulk Density as a Method to Evaluate Reducibility of Hard ...

Massive hematite ore (MHO) is a special highgrade iron ore used as lump ore in the process of obtaining direct reduced iron (DRI). The influence of porosity on the reducibility was investigated using optical and scanning electron microscopes. Hematite is the main component of the samples and occurs as granular crystals (10 m), microplates (1 m) and euhedral martite (10 to 30 m).

Understanding the highgrade iron ore market

iron ore market Mineralogy: hematite vs magnetite Iron ores can be formed of several different minerals; the most common are hematite and magnetite. DSOs, including the midgrade products Rio Tinto and BHP produce from Australia's Pilbara region and the highgrade 65% Fe fines Vale produces in Brazil, are predominantly hematite products.

Latest Posts

- المحاسبة كسارة الحجر في التفوق

- الروتاري آلة طحن للالبراغي

- صناعة كسارة الحجر في نيبال

- جدا مصانع طحن غرامة لالغوار

- ثمن كسارة متنقلة 300tph

- إنتاج ألمانيا الكلي

- الصناعية الكرة مطحنة الشركة المصنعة

- التعدين محامل مطحنة الأسمنت التعدين

- أرخص ماكينات التعدين بالصين للبيع في مصر

- أفضل مطحنة خلاط لأواني الطبخ الجزائرية

- طاحونة الكالسيت المطرقة للبيع

- الصين تعدين الذهب مصنع صناعة المملكة العربية السعودية

- قائمة أسعار الكسارة المطرقة

- التكلفة التقديرية لمشروع مصنع الاسمنت

- استخراج الذهب من خامات الذهب

- Por Le Trail Building Stone Crushers

- Sand Mining Quarry Silica

- Zenith Crusher Machine Blog Calcite Powder

- Marble Mining Equipment France

- Reporton On Stone Crusher

- Weed Crusher Swaziland

- Crusher In Pakistan Processing Coal Gold Africa

- Homemade Manual Stone Crusher

- Barite Stone Crushers

- Coal Mining Companies In Sa

- Ultrafine Grinding Mill In Paint

- Cobalt Crusher Used For Cobalt Ore Crushing Processing Plant

- Inding Ball And Grinding Ring For Coal Mill

- Mining Amp Amp Quarry Equipment South Africa

- Proses Bijih Emas Skala Kecil Di Senegal