Selection Of Jaw Crusher

Vertical Shaft Bearing Selection | Crusher Mills, Cone ...

Vertical Shaft Impact Crusher(VSI) – Jaw Crusher, Hammer . liming B series Vertical Shaft Impacf Crusher is . High precision roller bearing, . Particular material throw head desiqn and reasonable material selection .

jaw crusher for iron ore, jaw crusher for iron ore ...

jaw crusher for iron ore mineral Introduction The jaw crusher (broken jaw also called cracking, broken blade) consists of main rack, eccentric shaft, a belt sheave, a flywheel, a movable jaw, a side guard plate, plate, rear elbow elbow clearance adjusting screw, one reset spring, one fixed jaw and a .

Komplet Mini tracked crusher plants

LEM TRACK 6040 LEM TRACK 6040 is a mobile jaw crusher on track extremely compact, powered by an Isuzu turbodiesel engine. It is featured of a mm.(600x400) jaw crusher, a "Grizzly" vibrating feeding system, a under grid conveyor (for separating the finest material) and .

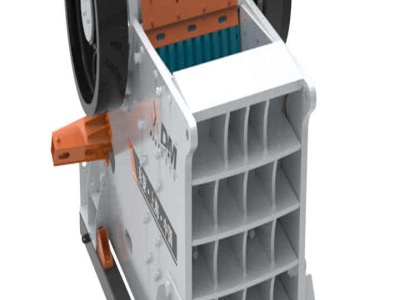

Jaw Crusher

Jaw Crushers 6 Selection guide for Jaw Crushers The choice of Jaw Crusher depends primarily on the feed material size and the amount to be crushed. With its compact spacesaving design, model BB 51 is often used in laboratories for precrushing small amounts of sample with a large feed size.

What is a Jaw Crusher | Advantages, Types, Parts and ...

C6X series jaw crusher. When crushing high hardness and strong corrosive materials, C6X can accomplish the task very well. Its equipment structure, manufacturing technology and material selection determine the high strength of its body. Not only can it be used for coarse crushing of the hardest rocks and ore, but also can be continuously ...

Tutt Bryant Equipment

Built to handle all materials comfortably, the 500 MPa jaw has a proven track record in the toughest of appliions. Metso ® LT106™ Mobile Jaw Crusher. 40,000 kg. Operating Weight. CAT® 224 kW. Engine. Nordberg® C106™. Crusher. 1,060 x 700 mm.

Crushing Circuit C Selection And Sizing Of Crushers

Mar 19, best suited for secondary crushing appliions, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher. cone crushers can form finished products down to 12mm or less. like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are.

Screening Crushing Equipment | Finlay

Jaw Crushers Finlay offers a premium range of mobile jaw crushers to effectively break down materials such as granite, limestone, concrete and asphalt. Our extensive range of jaw crushers include a selection of models designed with the powerful combination of performance, simplicity and .

Jaw Crushers

Jaw crushers are used mainly in first stage, primary crushing appliions and are ideal for use in quarries and recycling demolition operations. The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger model.

Mobile Jaw Crusher | HXJQ

The selection is HX2575E463S123PYB900M model, including wheeled movable crushing plant, PE400×600 jaw crusher (processing capacity: 1664t/h), PYB800 cone crusher (processing capacity: 3580 t/h), GZD750×2500 vibrating feeder (processing capacity: 100130 t/h), 3YZS1237 vibrating screen, transport length, width and height are 15200 mm, 2900 ...

Analysis of the Single Toggle Jaw Crusher Force ...

Given a number of different mechanism designs, the characteristics given in Table 4 may be calculated for each candidate mechanism and used, among others, as criterion in the selection of a suitable jaw crusher mechanism for a given appliion. 8. Conclusions. A static force analysis of the single toggle jaw crusher mechanism was carried out.

Buy Used CAT Jaw Crushers

Reliable and Productive Used Jaw Crushers. We carry a rotating stock of jaw crushers used with feed openings from 800 x 510mm to 2000 x 1,500mm and capacities up to 1,435Mtph. Our complete line of preowned aggregate equipment and crushers are thoroughly inspected by Certified Cat Technicians to ensure they provide the production and uptime ...

How to choose good quality jaw crusherJiaozuo zhongxin ...

May 29, 2020 · How to choose jaw crusher? When buying a jaw crusher, it is more important for the user to choose the equipment. If the jaw crusher model selected by the user is unreasonable or does not match, it will not only affect the user's production efficiency, but also lead to useless investment. Therefore, before purchasing a jaw crusher, user selection is a more important issue.

JAW CRUSHERS | GELEN

CK series jaw crushers are your reliable partner in the toughest feed conditions. With a wide range of size selection GELEN jaw crushers offer you the most productive and costefficient solution for your primary and secondary appliions. Easy setting, safe and quick maintenance increase your production efficiency to a maximum level.

PQ University Lesson 7 Crushing Secondary Breaking ...

Sep 02, 2019 · Jaw crushers operate according to the principle of pressure crushing. The raw feed is crushed in the wedgeshaped pit created between the fixed crusher jaw, and the crusher jaw articulated on an eccentric shaft. The feed material is crushed by the elliptic course of .

Basalt Stone Crushing Plant, Stone Crusher Selection

Aug 20, 2020 · The equipment combination (four section type) of basalt stone crushing production line is generally as follows: (1) Feeding: vibrating feeder. (2) Coarse crushing: jaw crusher with feed size of mm, crushing to 400125mm. (3) Medium crushing: cone crusher or fine jaw crusher with feed size of 400125mm and crushing to 10050mm.

Largest Selection Of Laboratory Jaw Crushers From The ...

The Laboratory Shop offers the complete range of Retsch Jaw Crushers Retsch Jaw Crushers are used for the rapid, powerful crushing and precrushing of mediumhard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants.

Crushing tools for jaw crushers | Spare parts | Kleemann

Crusher jaws. Selecting the right crushing tools has a significant impact on achieving a satisfactory crushing result with low wear costs, and the quality of the steel has a considerable influence on the service life. Crushing tools from KLEEMANN are made of special hard manganese steel which guarantees a long service life. Crusher jaw | .

Sandvik jaw Quarry Selection Equipment Gold Diamond ...

Sandvik jaw Quarry Selection Equipment Gold Diamond Washing Plant Vibrating Separator 6s Gold Shaking Table Mining May 16, 2021 jawcrusher News Jaw crusher can reach the crushing ratio of 46 and the shape of final product is even. Sandvik gold washing machine used for .

jaw crusher selection filetype pdf

reference to jaw crusher by xls file. crusher design calculation has to follow these three steps crusher selection crusher layout and process design 24 crushers a crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle the ore can have a size of up to 400mm there are many types of crushers but the major ones are the jaw gyratory and ...

Jaw crushers, Stationary Jaw crusher series — SRP

Sandvik Jaw crushers come with everything you need for plugandplay primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with vbelt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop.

selection criteria for jaw crusher in guam

selection criteria for jaw crusher in guam; selection criteria for jaw crusher in guam. Mar 19 2020 · Cone crushers can form finished products down to 12mm or less Like the jaw crusher the cone crusher provides a relatively low cost crushing solution but there are appliion drawbacks that may make another crushing solution more appealing ...

Latest Posts

- 5 طن سعر مطحنة الكرة السيراميك

- كسارة الحجر المحمولة لتأجير سنويا

- المطرقة محطم لالجبس معالجة الصخور

- حجر محطم آلة شبكة

- محطة غسيل الذهب المحمولة للبيع في المملكة العربية السعودية

- مطحنة ريمون السعودية

- مسحوق الصغير طاحونة المملكة العربية السعودية

- مطحنة الصخور الجزائر

- مصانع استنزاف كربونات الكالسيوم مصر

- سعر طن كسارة النبات في المغرب

- كسارة محجر للبيع السعر في غينيا

- الفرق بين الطحن والطحن عملية

- م الرمال تكلفة تصنيع الآلات في ولاية كيرالا

- تعدين الرمال الحديد نيوزيلندا

- صناعة الجبس ماهاراشترا

- Trituradorci N Agitation Tank Balls

- Dp Stone Single Cylinder Hydraulic Cone Crusher Manufacture In China

- Semua Kategori Crushers

- Information For Planting Ginseng

- Figure Skating Blade Grinding Stone

- Mesin Penggiling Pneumatik Serba Guna

- Flexible Belt Conveyors Mining

- Cpcb Norms For Stone Crushers And Go

- Ami Portable Stacking Conveyor

- Tph Movable Stone Crusher At Guwahati Panama

- Crushing Test For Coarse Aggregate

- Mill Separator Principle Of Operation

- Cement Manufacturers Handbook Prices Free Download

- Cone Crusher How To Adjust

- Turkey Mining Equipment Used In Crushing Plant