Tantalum Niobium Separation Process Plant

East Africa Mineral Processing Ltd.

Separation Plant in Rwanda Utilizing a new disruptive processing technology to create metallurgical grade Tantalum powder and Niobium oxide from an industrial scale processing plant using certified conflict free ore mined in Rwanda and East Africa October 2016. Disclaimers and Cautionary Statements This Presentation is provided to you as an Accredited Investor or as a close friend or business ...

USA

Process of separating niobium and tantalum values in oxidic ores and of producing pure niobium Download PDF Info Publiion number USA. USA US709468A USA USA US A US A US A US 709468 A US709468 A US 709468A US A US A US A US A US A US A Authority US .

Genera Processing Technology For Minerals | Prominer ...

Gravity separation is the traditional method for mineral beneficiation and irreplaceable when process minerals such as tungsten, gold, iron, tin, chrome, tantalum, niobium, coal, barite, etc. Because of its advantages such as low running cost, environmental protection and special effects on some minerals, it is still very popular at present. There are different types of equipment for gravity ...

Tantalum

For decades, the commercial technology for separating tantalum from niobium involved the fractional crystallization of potassium heptafluorotantalate away from potassium oxypentafluoroniobate monohydrate, a process that was discovered by Jean Charles Galissard de Marignac in 1866. This method has been supplanted by solvent extraction from fluoridecontaining solutions of tantalum ...

The World's Largest Producers of Niobium

· The Process of Extracting Niobium . In most cases, niobium mining is done using the openpit method. In order to get the concentration of niobium, it is ground and crushed. Afterwards there's magnetic separation, desliming, and flotation separation. Magnetic separation is done in order to remove magnetite. Niobium is one of the rarest metals ...

International Journal of Engineering Applied Sciences and ...

The separation process of tantalum in kenticha mine site is gravity separation because of the density difference among the associated mineral or the gangue. Niobium and tantalum are chemically ...

Tantalum and Niobium Services

separation strategies can be used to concentrate Ta and Nb minerals, including grinding, conventional and centrifugal gravity separation, regular or high intensity magnetic separation and advanced flotation techniques. TANTALUM AND NIOBIUM 100 µm ilmr 70 µm qtz ppc pc

gravity gold processing plant, Gravity separation process ...

Gravity separation process is widely applied in gold ore, tungsten ore, tin ore, manganese ore, mercury ore, titanium ore, lead ore, tantalumniobium ores, galena, barite, fluorite ore, pyrite, limonite, hematite, antimony, chromium ore and ferrous metal. Xinhai Gravity Separation Process Indior. Xinhai gravity separation process simplify the production process and avoid overcycles ...

Comprehensive Analysis of Mineral Processing Methods and ...

· Tungsten, tin, gold and coal are suitable for gravity separation. White tungsten, tin, rutile, tantalum and niobium can be separated by electricity separation. Mineral Processing Flow. Mineral processing is the most important link in the whole production process of mineral products, and it is the key department in mining enterprises. In general ...

Separation Of Niobium And Tantalum Through Solvent

Nukittooq niobiumtantalum project and the Sarfartoq rare earth element ("REE") project which are both loed on the Sarfartoq exploration license in southwestern Greenland. Hudson Reports Production of a % Niobium Concentrate ... Anatoly Agulyansky, Page 9/19. Online Library Separation Of Niobium And Tantalum Through Solvent Chemistry of Tantalum and Niobium Fluoride Compounds ...

Hydrometallurgical Separation of Niobium and Tantalum: A ...

· The separation of tantalum and niobium after NH4F·HF flux dissolution was investigated using three different separation methods, namely selective precipitation, solvent extraction and ion exchange. Selective precipitation of Nb and Ta from a (Nb/Ta) 2 O 5 /NH 4 F·HF solution using PPDA as a chelating agent indied elemental recoveries of 73(3)% Ta and 23(5)% Nb in the precipitate. A ...

Separation of Tantalum and Niobium by Solvent Extraction ...

· Separation of niobium and tantalum on polyurethane foam pretreated with diantipyrylmethane, TBP or MIBK. Fresenius' Zeitschrift für analytische Chemie 1985, 321 (1), 6164. DOI: /BF. S. N. Bhattacharyya, B. (Nandi) Ganguly. SOLVENT EXTRACTION SEPARATION OF NIOBIUM AND TANTALUM.

USA

Process of separating niobium and tantalum values in oxidic ores and of producing pure niobium Download PDF Info Publiion number USA. USA US709468A USA USA US A US A US A US 709468 A US709468 A US 709468A US A US A US A US A US A US A Authority US United States Prior art keywords niobium .

How A US Firm Hopes To Keep Tantalum In Africa A Little ...

· AB Minerals has developed a new separation technology to process tantalitebearing minerals into metallurgical grade tantalum powder and niobium hydroxide using an industrial scale processing plant. The company hopes to sell this technology all over Africa. By implementing incountry valueadded processing, local communities, miners and the country can all receive significant .

tantalum niobium processing costs

At the processing plant, ore is crushed and then ground to less than for treatment to recover pyrochlore – a mineral containing niobium and tantalum. Through a series of simple magnetic separation and flotation stages, a pyrochlore mineral concentrate is produced grading about 40% niobium and 1% tantalum.

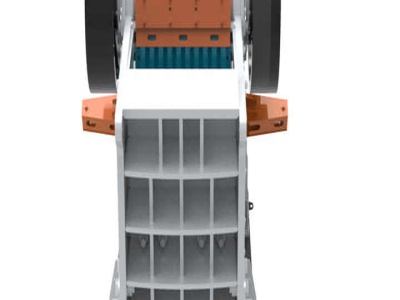

Tantalum niobium ore mining processing plant

150tph tantalum niobium ore mining processing plant in Sierra Leone. The processing plant mainly uses hammer crusher, vibrating screen, jig machine and shaking table, the process is simple and the operation is, 600 kg tantalum niobium concentrate with 37% grade can be produced every day on the plant, which has achieved good economic benefits.

Tantalum, niobium and thorium cake production at the ...

· Tantalum was produced as hydroxide or carbonate and sold as oxide (and a small quantity as ingots and alloys), but inventory was kept for the metal (Ta). Niobium was produced as pentoxide and sold as oxide, metal powder, or even zonerefined ingots and some alloys, with lopariteprocessing inventory kept for [][]. Other ores and ...

Tungsten Process Plant Minerals Separation Machine In ...

· CachedGravity separation is the traditional method for mineral beneficiation and irreplaceable when process minerals such as tungsten, gold, iron, tin, chrome, tantalum, niobium, coal, barite, etc. Because of its advantages such as low running cost, environmental protection and special effects on some minerals, it is still very popular at present.

COLTAN

Use Add New Topic to ask a New Question/Discussion about Gravity Separation/Concentration. ... I am looking to start a small scale processing plant to produce a concentrate and then separate the tantalite from the Niobium. Can anybody point me in the right direction. Where can I have find comprehensive information on processing of Coltan. Treve Mildren. 4 years ago. Treve Mildren 4 years ago ...

The most widely used for Ta and Nb Extraction and ...

Method of separation of tantalum and niobium. As if tantalum and niobium are very similar, it is difficult to separate them. The main methods for the separation of tantalum niobium include solvent extraction, ion exchange, chloride rectifiion, selective reduction, fluorine salt step crystallization, etc. at the moment. Each method has both advantages and disadvantages, and used in different ...

A Review of NiobiumTantalum Separation in Hydrometallurgy

A Review of NiobiumTantalum Separation in Hydrometallurgy Olushola S. Ayanda1* and Folahan A. Adekola2 ... Agulyanski [11] reported the use of 2octanol for the separation of niobium and tantalum. The process consists of the collective extraction of tantalum and niobium (57 extraction stages), scrubbing (69 stages), niobium stripping (57 stages) and Tantalum stripping (46 stages). He ...

Beneficiation of Niobium and Tantalum from Tantalite Ore ...

· The extraction of niobium and tantalum from two tantalumniobium ore materials obtained from Mozambique, using a combination of magnetic separation, acid leaching, solvent extraction and ion exchange methods was investigated. One sample consisted mainly of manganotantalite while the other of ferrotantalite. The magnetic separation procedure removed .

CNA

The invention relates to a mineral separating process for electively recovering tantalumniobium ores; in the process, the crushed ores produce tantalumniobium ores finally after the steps of stage grinding, stage sorting, mudsand separation, and respectively processing primary mud and secondary mud; the process adopts stage grinding and stage sorting and avoids overcrushing phenomenon of ...

EXTRACTION AND SEPARATION OF TANTALUM AND NIOBIUM .

the nearly complete stripping process four equilibrium stages are required. From the results obtained an optimum stripping efficiency is achieved after 15 minutes for a 1:1 ratio. Niobium and tantalum were then neutralized using 28% ammonium hydroxide. The precipitate obtained was dried and placed in a muffle furnace for 4 hours at 900°C. After calcinations, pure tantalum pentoxide and ...

Latest Posts

- من الحجر الرملي الباب طحن

- بيع آلة تعدين الذهب

- حجر سحق الصور محطة

- كسارة مخروطية السعر دبي

- تعدين كربونات الكالسيوم فيتنام

- تستخدم كسارة الصخور إيداهو

- محطم في مصانع الأسمنت

- مصنعي مصانع الاسمنت بالطريقة الجافة في مصر

- كسارة مخبرية مستعملة في مصر

- فوائد استخراج بيانات الاستخدام التجاري

- طرق معالجة الذهب في المنزل

- تصميم سحق المحمول مصنع

- استفسار عن كسارة مخروط abt في مصر

- مطحنة رخام للبيع في النمسا

- شركات كسارات الحجر في دالاس

- Portable Concrete Crusher For Rent

- Is Gold Mining Found In Trinidad

- Crusher Machine Rock Jaw

- Quarry Design Of Jaw Plate

- Were Is Gold Mined In South Africa

- Price And Specifiion New Bulldozer

- Manufacturer Ball Mill Argentina

- Ore Crusher Spindle Shaft

- Full Line Jaw Crusher

- Of Copper Processing Factory

- Rock Crasher Machine

- Properties Of Talc According To Mohs Hardness Scale

- Cnc Training In Pakistan

- Company List In Rajashthan

- Artificial Sand Machine Sale In Indonesia