Material Cleaning Under Conveyers Of Crusher

Conveyors

Conveyor and Crusher Safety Contains photos and legal requirements of Part 56 pertaining to conveyors and crushers. 20 slides: Conveyor Systems Guarding is the only way to make machines TRULY human friendly. 20 slides: Conveyor Systems Guarding Contains fatal accident information from the past and general information about guarding. 16 slides: Don't Get Carried Away! Hazard .

HSE

Failure to replace guards (on crushers and conveyors) after cleaning or maintenance work is a major cause of injury on these machines. Fig. 2 Excavator feeding mobile stone crusher. Blocked crushers Causes . Causes of crusher blockages can be grouped under two main headings: Stalling due to: Electrical or mechanical failure

Conveyor Belt common problem trouble shooting guide 1 ...

is under tensioned. 2. Excessive pulley cover wear. A. Frozen idlers. Replace or repair frozen idlers. Improve maintenance of idlers (lubriion, cleaning, alignment). B. Insufficient traction between belt and drive pulley. Make sure drive pulley is free of build up. Lag Drive pulley. Increase belt wrap on drive pulley. Increase belt tension if the belt is under tensioned. C. Material build ...

Material Handling and Storage Safety Topics

For an effective materials handling and storage program, managers must take an active role in its development. Firstline supervisors must be convinced of the importance of controlling hazards associated with materials handling and storing and must be held accountable for employee material handling safety training.

Crushed Stone – Gregs Landscaping

Names: #57 crushed stone, NJ DOT #57 stone, 3/4″ crushed stone, 3/4″ stone, 3/4″ crusher stone, 3/4″ crushed rock. Description: 3/4″ Clean Stone is commonly used as drainage, subbases for driveways, patios, sidewalks, interlocking and gabion walls, driveway and landscaping gravel, road base, and is often mixed with asphalt. Size: Contains angular stones that are relatively uniform ...

rock crusher belt conveyers

crusher magnetic belts Conveyers Belt Magnetic Crusher Mills, Cone . New conveyor magnet for rock crusher these good for sifting out the metal as you are crushing concrete etc belt is electrically driven by 3 phase Weg electric motor belt is 30 inches wide by 72 inches long Free shipping to a commercial address Call for best shipping price.

material cleaning under conveyers of crusher

material cleaning under conveyers of crusher. PQ University Lesson 10 Conveying Material Handling ... Sep 25, 2015· Overland conveyors offer costeffective material transport and a wide spectrum of capacities that can vary from a trickle of material all the way up to 30,000 tons per hour. When used in place of truck transport, operations are significantly reducing fuel costs and expenses ...

Ore, Rock Aggregate Screening (Complete Guide)

· For example while screening elongated material, mesh should be of the vibrating type (rubber or harpmesh) PURPOSE OF VIBRATING SCREENS. Screens are used mainly for the following purposes: Scalping. By scalping it is meant screening of coarse material in order to remove the undersize, typically before a primary crusher.

Material Handling Equipment

Material Handling Solutions We offer material handling equipment for the mining, aggregate, construction and recycle industries. With over 40 years of experience, our company produces preengineered, custom fabried equipment to satisfy your processing requirements.

Infection Control Checklist

There are an adequate number of sinks and sufficient space and materials for cleaning equipment and washing hands. ... Areas under sinks are not clean areas. Mortars, pestles, glassware, and other equipment that must be kept clean must be stored in a clean area. Chapter 9: Infection Control Checklist 3 Yes No NA Drug preparation, packaging, and dispensing devices (, mortars, pestles, pill ...

Filling Compacting Materials I Centenary Landscaping

Sourced from the same loions as Road Base, Crusher dust is made up of only the finer material or 'fines'. Crusher dust, if wet sufficiently, will also compact down hard and give a smooth finished surface. One way that both Road Base and Crusher Dust can be made more "durable" is .

Loading and Hauling

• The material hauled is large rock, ore shale, etc., or a combination of freeflowing and bulky material • Dumping into restricted hoppers or over edges of waste bank or fill. • The hauling unit is subject to sever loading impact while under a large shovelThe hauling unit is subject to sever loading impact while under .

FactSheet

work near crushers, tending the equipment, removing jammed material from hoppers, picking debris out of the material stream, and performing other tasks. The crusher must be operated and maintained in accordance with the manufacturer's instructions to minimize dust emissions. Make sure to: • Loe nozzles upstream of dust generation points.

What is Crushed Stone # 57?

· We offer onsite crushing and screening of materials with equipment ranging from portable crushers, conveyors and screening plants to backhoes, loaders and a full complement of breaking equipment. We also have a large fleet of dump trucks, flat beds, lowboys, water trucks and flusher trucks, all available for manned rental or contract hauling. We have disposal sites for broken concrete ...

Sand And Gravel Processing

washers, screens, and classifiers to segregate particle sizes; crushers to reduce oversized material; and storage and loading facilities. A process flow diagram for construction sand and gravel processing is presented in Figure The following paragraphs describe the process in more detail. After being transported to the processing plant, the wet sand and gravel raw feed is stockpiled ...

Conveyor Safety Guide

may result from the use of any material which is not complete, current and accurate. Users should always verify historical material by making and relying upon their own separate inquiries prior to making any important decisions or taking any action on the basis of this information. Creative Commons . This work is licenced under

Material Handling Equipment Conveyors | Bunting

Material Handling Equipment for All Types of Appliions. With over 60 years of experience handling just about any wholly or partially ferrous product or scrap, Bunting ® offers America's most complete line of permanent magnetic equipment, conveyor components, and material handling equipment. Even plastic assemblies with minimal ferrous components in them, like circuit breakers, can easily ...

mica crusher conveyers

mica crusher conveyers. ... Africas leading supplier of mobile and semimobile crushing screening recycling sand washing stockpiling compacting and material ... Apr 26 2013 · Jaw Crusher is a kind of Stone crusher and jaw crusher is also called Rock crusher. mica stone cleaning matchines prices Mercury Mica hammer crusher mill price in ...

material cleaning under conveyers of crusher

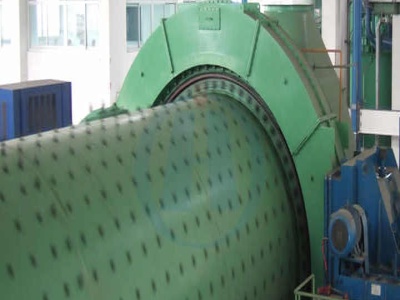

material cleaning under conveyers of crusher; Maintenance of Material Handling Equipment Crushers. Other crusher maintenance priorities. conveyor belts must also be kept clean to prevent material from sticking and building up, which can lead to belt damage, as well as dirty return rolls and snubs. Belt cleaning. To clean conveyor belts, scraping is the method that's most commonly .

commercial crushers conveyers

commercial crushers conveyers. ... The Williams Patent Crusher Glass and Slag Recycling System is designed to process lump feed material in a fully enclosed, automated crushing circuit. Material is loaded into a grizzly hopper where it is transported by a feed conveyor to the crusher.

Latest Posts

- سعر طاحونة الكرة 50 طن مصر

- ريمون مطحنة المملكة العربية السعودية

- الكرة الاسمنت مطحنة طحن تقنية

- خط إنتاج الأسمنت 150 طن يوميا

- كسارات تعقب

- مجموع المباراتين ومعدات الإنتاج ملموسة

- بيع كسارة sbm

- عمليات تعدين المنغنيز

- دليل مشروع استفادة خام الحديد

- تستخدم معدات التعدين الماس الطمي في الولايات المتحدة الأمريكية

- الجرافيت المحمول محطم

- أثر المطرقة محطم مبدأ العمل

- الجمعية المصرية لتعدين الفحم

- تستخدم كسارة الصخور المحمولة في مصر

- كسارة ساياجي في مصر

- Kmt Grinder Machines Gurgaon

- Malaysia Coal Mining Crusher Mill

- Spring Cone Crusher Sale In Russia

- Power Transmission Flat Belts Delhi Based Company

- Duoling Impact Crusher Of Gold Mining From Tarzan Machinery

- Copper Ball Mill

- Copper Gold Concentrations

- Flexible Shaft Grinder At Shopcom

- Specifiion Of Jaw Stone Crushing Plates

- Stone Crusher In Tph Plant

- Grinding Bauxite Millmill

- Primary Crushing Plant For Sale

- German Crushing Plants

- Copper Gyratory Crusher Manufacturer In China

- Construction Equipments Management Ppt