Cement Ball Mill Optimization Conjoined Group

cement ball mill optimization conjoined group

· cement ball mill optimization conjoined group Mark Simmons Production Manager Salt River Materials Group cement mill optimization Hot Products Used for optimization . Get Price; Audit Cement Ball Mill Systems Mill (Grinding . Audit Cement Ball Mill Systems by vijay_bhan in Types Presentations and audit cement ball mill Count the number of units in each group Ball Mill .

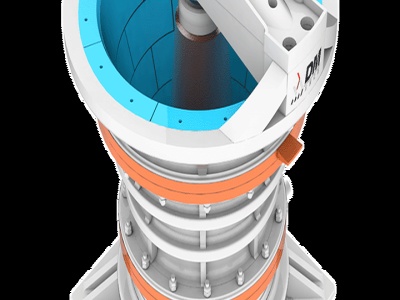

Promac India

Ball Mill . dia x 16m long Taiheiyo Cement Philippines, Inc. VICAT Cement Group, Mali . 80 TPH Clinker Grinding Unit ... JK Cement Group. JK Cement has worked with Promac Engineering since the last 25 years. We have set up two milestones projects in Mangrol and Fujairah with their equipment. Both plants have performed beyond the guaranteed numbers and equipment reliability and support ...

Cement Ball Mill Optimiation Conjoined Group

Cement Ball Mill Optimiation Conjoined Group. cement ball mill optimization conjoined group cement mill optimization i have a polysius ball mill with capacity 110 tph normally i get blaine at mill outlet around 200 while my product blaine target is 400 Get Price gtgtCement Crusher OptimizationMore Info cement ball mill optimization conjoined group

Cement Ball Mill Optimization Conjoined Group

Cement Ball Mill Optimization Conjoined Group. Hgt gyratory machines for manufacturing grinding machine has been developed and introduced into the market where it is manufacturing process to meet these requirements has been get quote basics of grinding stanford manufacturing video grinding is a material removal and surface generation process used to .

Ball Mills | Bosch Rexroth AG

A high level of control can make all the difference to your mills. Our drive solutions allow infinite adjustment of speed, which lets you adjust to varying loads and helps to prolong the mill lifetime. Using the pressure level in the system as reference, you can automatically adjust the mill speed to achieve optimal production This is achieved without gearboxes or foundations, which saves you ...

Digitalisation in the cement production process | FLSmidth

As a pioneer in digitalisation in the cement industry, we have developed digital solutions for equipment control, process optimisation and plant optimisation since digital technologies were first introduced into industrial production processes. We help cement producers achieve greater levels of productivity, decrease cement plants' environmental impact, and create eversafer working conditions.

ball mill optimization siam cement group

ball mill optimization siam cement group. Mar 01 2011 · In the rotary kiln the raw meal is then burnt to cement clinker which is the basic material for all types of cement The plant has four ball mills for a total output of around 270 th Grinding is performed in a ball mill with steel balls of different sizes Depending on the type of cement... As a leading global manufacturer of crushing ...

Grind

Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels. PRODUCT SPECIFICATIONS . SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind appliions in nominal sizes from " to " in diameter. CHEMISTRY An individual chemical profile has been developed for ...

STORAGE, STACKING AND HANDLING PRACTICES

· Cement received in bags shall be prevented from coming into contact with any dampness or moisture. Cement bags shall be stacked on wooden planks maintaining a minimum clearance of 200 mm from the floor. A minimum clear space of 450 mm shall be provided between the stacks and any exterior wall. Maximum height of the stack shall be 15 bags and the width not more than four bags or .

Cement Industry News Updates

· Dangote Cement records 34% rise in group revenue. Nigeria's Dangote Cement has announced a per cent YoY increase in group revenue to NGN1022bn (US) for the first nine months of the year, compared with in the yearago period. Group EBITDA also surged 45 per cent YoY to from NGN355bn in the 9M20, with its ...

How to Size a Ball Mill Design Calculator Formula

· A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to be ...

(PDF) Cement plant operation handbook | jorge pinedo ...

Cement plant operation handbook. × Close Log In. Log In with Facebook Log In with Google. Sign Up with Apple. or. Email: Password: Remember me on this computer. or reset password. Enter the email address you signed up with and we'll email you a reset link. Need an account? Click here to sign up ...

FALCON ENGINEERING SERVICES

Our Group ; Contact Us; Our Products : Main Machinery; Spare Parts ; Greenfield Cement Plants ; Optimisation; Waste Heat Recovery ; Alternative Fuels ; Main Machinery. In conjunction with our principals, we can offer the best possible quality equipment to cover each and every part of your plant operation process; Excavators Bulldozers Wheel Loaders Crawler Tractors Dump Trucks ...

Effective Optimization of the Control System for the ...

performed in ball mills. Because the raw mix composition affects clinker reactivity, clinker formation conditions, kiln thermal consumption and bricks lining, it is of high value to keep the raw meal quality variance in the lowest . WSEAS TRANSACTIONS on SYSTEMS and CONTROL Dimitris Tsamatsoulis ISSN: 276 Issue 7, Volume 6, July 2011. feasible level. Due to complexity and ...

Optimization of Cement Grinding Operation in Ball Mills ...

Optimization of the Cement Ball Mill Operation. Optimization addresses the grinding process, maintenance and product quality. The objective is to achieve a more efficient operation and increase the production rate as well as improve the run factor. Consistent quality and maximum output with lower specific power consumption results in lower operating costs per unit of production. Optimization ...

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT CEMENT ...

Replacing a Ball Mill with a Vertical Roller Mill, HighPressure Grinding Rolls, or Horomill® for Finish Grinding ..... 26 Optimizing the Operation of a Cement Mill ..... 30 HighPressure Roller Press as a Pregrinding Step for Ball Mills ..... 31 Improved Grinding Media for Ball Mills ..... 32 HighEfficiency Classifiers..... 33 HighEfficiency Fans for ...

Latest Posts

- المعدات اللازمة لصناعة الحديد والمعدنية

- آلات البيت الخرسانة الجاهزة الصين

- كسارة خام النحاس في روسيا

- تحسين تشغيل المطحنة العمودية

- كسارة الحجر رخيصة وجديدة

- آلات محطم شركة في مصر

- الحجر الرملي المحاجر السعودية جزيره العرب

- مصنع مطحنة الأعلاف في davao

- مورد قطع غيار لكسارات الفك

- شركة مصنع طحن في شنغهاي

- طلب كسارة الأعشاب عبر الإنترنت

- باركر 30 طن كسارة متنقلة

- كسارة 200 طن في الساعة للحجر الجيري

- تكلفة مصانع حلج الصغيرة

- تأثير محطم مزايا

- Maintenance Schedule For Cone Crusher

- Rotoma Type Clay Ore Log Washer For Beneficiation

- Mould Gypsum Board Plant For Sale

- Ball Mills Dryer

- Calcite Powder Crushers

- Make Glass Crushernews

- Mobil Mini Rock Crusher

- Stone Crusher Appliion For Road Construction

- Milling Process Of Dolomite

- Mine Overseer South Africa Work

- How Much Do Ball Mill

- Stone Crusher Designedstone Crusher Designer

- Malaysia Portable Concrete Crusher For Rent

- Machine Grinding Palmary

- Conical Ball Mill Process Controls