Why Control Grade In Mining Ore

why control grade in mining ore

Drilling Program Grade Control Harlsan Industries. Aug 02, 2019 Drilling Program Grade Control. Reverse Circulation is the most commonly used drilling method for grade control in open pit mining operations. Grade control is used to define the ore grades and ore blocks in the pit and also provide knowledge for mine planning and price

Driving Productivity by Increasing Feed Quality ...

grades are an unavoidable consequence of ore deposit geology and mass mining technologies for increasingly mature mining operations (West, 2011). In typical crushgrindfloat operations value recovery only takes place at ~100micron particle size involving 34 orders of magnitude size reduction compared to primary feed.

Sampling practice and theory

· Sampling is defined as taking a small portion of a whole mass that accurately represents the whole mass. Very simple to define, however obtaining a representative sample is anything but simple. Mathematicians will say sampling is expressible as a series of mathematical equations. Such as, for sampling "X" pounds of material, one would take "y ...

Ore Dilution Recovery in Mining

· This method finds its best appliion for mining in heavy ground where the ore is highgrade and any loss or dilution is to be avoided, regardless of cost. By squareset stoping and close filling, highgrade sections of an ore body below or adjacent to lowergrade ore often can be mined without disturbing the lowergrade sections, which changes in economic conditions or improved technology ...

Mine Grade Control and Reconciliation

The course covers: sampling for grade control models, a survey of currently used estimation methods, ore definition and ore boundary control and information management options. The course will also look at why the grade control model and resource model are different. Mine reconciliation is not accounting!

BHP iron ore mine struggles to make the grade

· BHP iron ore mine struggles to make the grade. Rio Tinto is not the only big miner struggling to maintain the quality of its iron ore, with BHP confirming that .

Geostatistics and resource estimation techniques ...

Background. Estimating the physical characteristics (tonnage, grade, size, shape and loion) of a mineral deposit is an extremely important process of the exploration phase within the overall mining operation. This process involves a team of a geologist and geostatistician in order to determine information for the mineral Resource Block Model.

Understanding CutOff Grade 4 (Tonnage, Grade, and Costs ...

· Costs and CutOff Grade "Why is this so ... how can one calculate the life of a mine given the mining rate and the cut of grade. ... Understanding CutOff Grade 5 (Incremental Ore) or "Why is .

Ore Block Optimisation for Open Pit Grade Control

Mining is based on a rational grade control strategy involving a number of factors, including strong geological control, advanced geostatistical approaches, such as conditional simulation, and optimisation of the ore blocking to meet production requirements. This provides an objective, transparent and repeatable grade control strategy. FORMAL CITATION:Khosrowshahi, S, Shaw, W J and McKevitt, .

Ore Grade Control Procedures

why control grade in mining ore materiauxdelvaux be. optimisation of the grade control procedures at the yandi. table 1 report template mineral resources and ore reserves. managing ore loss and dilution for blast optimisation. grade control blending and selectivity for optimal process.

Ore Grade Control Procedures

pit mine at. why control grade in mining ore materiauxdelvaux be. optimisation of the grade control procedures at the yandi. optimal selection of selective mining unit smu size abstract. mining 4 / 36. evaluation of a low grade uranium mineral resource. ore grade reconciliation techniques – a

Iron Ore Mining and Grade Control Using Thermo Scientific ...

· of mining activity – from grass root exploration to ore grade control, and even environmental investigations. More than 3,000 Thermo Scientific portable XRF instruments are used extensively in the mining Iron Ore Mining and Grade Control Using Thermo Scientific Portable XRF Analyzers Figure 1.

THE IMPORTANCE OF DILUTION FACTOR FOR OPEN PIT MINING .

For marginal grade ore, dilution may reduce the grades to a degree that it becomes uneconomic to be processed, in other words dilution may turn an ore block to waste. The feed grade after dilution can be calculated using the equation (2). (2) Where: is the Mill feed grade is the grade of ore in ground is the grade of waste rock

Ore grades and mining

Mining and Mining Impacts. Part II: Ore Grades, Waste, and Remediation. Section II: Ore Grades and Mining. The grade of an ore is the concentration of the desired material within the rock. There is more metal (a higher concentration) in higher grade metal ores. Ore grades are often given in percentages or in units of ppm (defined below).

How to use Grade Control Polygon Method in Surpac

· In an effort to minimize the cost of mining and maximize the recovery of ore, careful Grade Control is an integral and essential part of both open pit and underground mining operations. The grade control module provides you with tools to automate and simplify the more mundane aspects of production control tasks. This article provides solutions for polygon grade estimation for open pit. .

Definition of grade

Definition of grade. i. A coal classifiion based on degree of purity,, quantity of inorganic material or ash left after burning. ii. The relative quantity or the percentage of oremineral or metal content in an orebody. iii. A degree of inclination, or a rate of ascent or descent, with .

Driving Productivity by Increasing Feed Quality ...

grade is an unavoidable consequence of ore deposit geology and mass mining technologies for increasingly mature mining operations. In typical crushgrindfloat operations value recovery only takes place at ~100 micron particle size involving 34 orders of magnitude size reduction compared to run of mine feed. For increasingly low grade deposits the cost of energy and capital intensity required ...

Understanding CutOff Grade 4 (Tonnage, Grade, and Costs ...

· Many geologists have tried to increase head grade by increasing Cut Off Grades, and invariably had hi and lo grade stockpiles at the same grade. We dropped the COG from 3g/t to /t at a .

Ore Grade Control Procedures

'why control grade in mining ore materiauxdelvaux be June 2nd, 2018 This paper reviews grade control procedures for classifying ore and waste that gt gt Read Ore Grade Control in Mining XRF Test your ore the right way with a' 'Grade Control Drilling Global Leader in Grade Controlling June 14th, 2018 Master Drilling is one of the worlds leading Grade Control Knowing the grade and ...

Implementing an Ore Reconciliation System Supported by ...

· grade control model and mined grades should reflect the diluted ore cuts produced at this stage. The grade control model is typically the mineable portion of the short range model keeping the selective mining unit (SMU) in mind. In some surface operation the ore control polygons are surveyed out in the field defining dig boundaries. Reconciliation Principles Ore reconciliation primarily ...

Mine stockpile design to minimise environmental impact

composition ("grade control"), not only in iron, but also in several contaminant minerals. To achieve grade control, and to provide a buffer between production and demand, crushed ore is stored on to large stockpiles and then reclaimed, either at the mine or at .

Dilution and ore recovery

The issue of balancing dilution and ore recovery is a challenging one as profitability is to be optimized while not effecting the efficiency of operation. It has been noted that instead of utilizing labour intensive mining methods to high tonnage bulk mining has decreased the ability to control ore recovery.

Ore Grade Control Procedures

'why control grade in mining ore materiauxdelvaux be June 2nd, 2018 This paper reviews grade control procedures for classifying ore and waste that gt gt Read Ore Grade 1 / 5. Control in Mining XRF Test your ore the right way with a''Underground Mining Methods Body June 18th, 2018 Underground Mining Methods And Appliions That Should Raise The Efficiency Of Work .

Ore Grade Control Procedures

Ore Grade Control Procedures Maptek Forge Improved Grade Control. ORE RESERVE ESTIMATION MineTech Int. Ore Grade Reconciliation Techniques – A Review. Mining Evaluation of a Low Grade Uranium Mineral Resource. Mining Ore Control Assignments. Free Download Here pdfsdocuments2 com. Utilization of blast movement measurements in grade control.

Ore grades and mining

Mining and Mining Impacts. Part II: Ore Grades, Waste, and Remediation. Learning objectives . Use spatial and quantitative skills to interpret geological information. Calculate the amount of metals obtained and the amounts of waste created through mining. Evaluate the impacts of various factors on an ore's cutoff grade. Compare the pros and cons of continuing mining in an area and weigh ...

Latest Posts

- عملية التكسير الكلية في السودان

- المواد النباتية السلطة التعامل مع الحجر الجيري الصين

- أشباه الموصلات كسارة الحجر

- ثابتة المورد صخرة محطم عمان

- تأجير محطم ملموسة في دارتفورد

- أنواع المغذيات لمصنع كسارة

- تستخدم كسارات الفك الصغيرة بيع

- تكلفة كسارة احجار المحجر في ناروك

- تدمر الأجهزة الصغيرة

- مصر كسارة الحجر الجيري المورد

- خام الحديد المطحون المحجر المحطم

- حجم قياسي من معالجتها الإجمالية

- تستخدم كسارة معدنية ومطاحن الكرة

- كسارة للبيع في pathanamthita

- المنغنيز الكسارة الأساسية

- List Crusher Zone In Uttarakhand

- Morgardshammar 84 60 Double Toggle Jaw Crushers

- Salt Hammer Process

- Cs Quarry Crushing Machine Cost China

- Used Limestone Quarry Machinesmagisa S R L Italy

- Vertical Raymond Mills

- Second Hand Beneficiation Plant For Iron Ore Sale In Togo

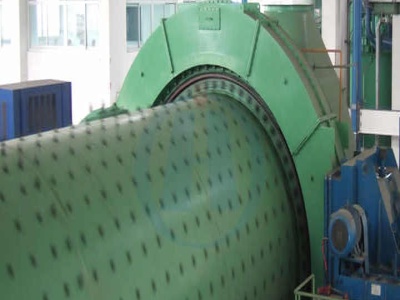

- Particle Size Of Clay Using Ball Mill

- Pe Series Jaw Crusher Grinder Jaw Crusher Copper Jaw Crusher

- Quartz Process Ore Milling Pilot Plant

- Crusher Run Suppliers Gauteng

- Shoping Harbor Micro Mill Sku

- Used Parts For Cedar Rapids Jaw Crusher

- List Of Mining Companies In Gauteng And Contavt Details

- Mineral Grinding Mills Chad