Grinding Of Mining Materials Industries

Manufacturer of raymond roller mill ultra fine grinding ...

Raymond mill is widely used in metallurgy, building materials, chemical industry, mining and other fields of mineral materials in grinding processing . Guilin Hengda mining machinery co.,ltd is a leading manufacturer of raymond mill, ultra fine grinding mill,Vertical grinding mill with Support Facilities It's producting raymond

GUIDE TO THE MOST COMMON TYPES OF MINING ...

Dec 23, 2015 · Directional drilling is also a type of mining technology where miners will use the tools and certain methods to drill wells. 2. Blasting Tools Blasting tools are an essential part of the mining industry and are used to break down and fracture materials (usually rocks) by use of a calculated amount of explosive until it's broken down.

Industries

The roundtool and cutter manufacturing industry has been central to our business since 1996. We provide our customers with a range of resin bond, polyimide, hybrid, metal bond, electroplated diamond and CBN grinding wheels, helping our customers manufacturing drill bits, reamers, hobs, broaches, endmills and many other products.

A discussion on the measurement of grinding media wear ...

Jul 01, 2016 · Grinding media wear assessment – laboratory tests. Rendón and Olsson observed that rocks and minerals subject the mining equipment to severe wear conditions, which has led the mining industry to consume growing amounts of wearresistant materials. In handling and transport operations, it is often possible to reduce the wear of components by ...

Grinding Techniques

Apr 24, 2021 · Grinding Techniques – Preferred Partner to the Essential Pipeline Industry. by FORTUNE April 24, 2021 0 61. With an estimated 3800 kilometres of petroleum pipeline in South Africa it is safe to say that the Pipeline Industry is an essential part of the country's economy. Numerous manufacturing concerns are involved in this industry ...

Grinding Equipment | Beneficiation Equipment

Nov 14, 2013 · Grinding equipment and machineries in Australia is very popular as well because of the developed mining industry. There are many suppliers and manufacturers of grinding equipment and machineries in Australia. Here is a brief introduction of some grinding machines for .

Cement Ball Mill

Dec 10, 2019 · What is the cement ball mill? The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power. Cement grinding is the last process of cement production, it is to mix cement .

Portfolio

Cyllindral Grinding, Vertical Grinding, Surface Grinding. For over 6 decades, Industrial Grinding has offered machine breakdown repair to any company in the manufacturing industry with a moving part. Our extensive inhouse grinding and metalizing capabilities enable us to repair worn machine parts such as gear shafts, drive spindles, as well as spindle housings.

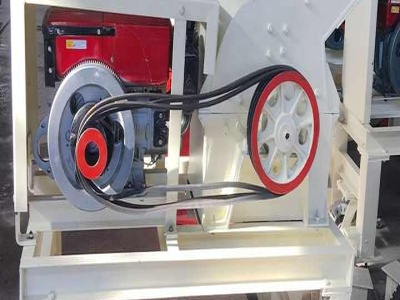

The importance of jaw crushers in the mining industry

Apr 09, 2021 · It is mainly used in the first crushing operation of the production line to crush large pieces of material, and then enter other crushers to complete the crushing operation. It is used in the crushing of various ores and bulk materials in mining and smelting, building materials, highways, railways, water conservancy and chemical industries.

Mineral and Mining Engineering: What are the differences ...

Answer (1 of 4): Crushing and Grinding are a must in the Mining Industry, and indeed they are essential stages. The main target / purpose for both is to reduce the size of the ore (rock) particle before subjecting it to reagents (chemical reactions). Crushing involves reducing the ore size from v...

Grinding

Grinding equipment for mineral processing. The final fineness of the product mainly depends on the number of times the ore particles pass through the grinder. The longer the grinding, the smaller the particle size. Separate crushing and grinding steps are necessary, the ball mill can only receive the broken ore particle, and then grind to the ...

Grinding Aids and Scale Control

Grinding Aids and Scale Control. BASF's Solutrix™ dispersants for mineral slurries are effective dispersants and rheology modifiers for calcium carbonate, kaolin and other minerals suspensions. In wet grinding appliions, the rheological behavior of mineral slurry is an indiion of the level of interparticle interaction or aggregation ...

Industrial Material Testing, Testing Instruments: Grinding ...

Industrial Material Testing Laboratories Instruments Used for cutting grinding of large specimens and cutting, lapping and polishing sample preparation in automotive industry for making cars. We are suppliers, manufacturer and distributors partner of Industrial Material instrumentation comes under industrial materials testing. Grinding Machine, Samples Cutting, Ultrasonic Cleaners.

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator ...

Grinding media is grinding feed; High capacity (short retention time) Sensitive to feed composition (critical size material) SemiAutogenous Grinding (SAG) Mill. Wet or dry; Higher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball 125 mm)

Graphite Processing,Extraction,CrushingGrinding Plant ...

Prominer is experienced in choosing the suitable grinding mill to reserve high yield rate of big flake graphite. With the development of expanded graphite and anode materials industry, there is much requirement on high purity graphite product. It is very hard to reach the grade above TGC 96% just by the stage grinding and flotation processing.

Latest Posts

- مصر كسارة مخروطية قصيرة

- مثال على مشروع محجر الحجر

- استرداد مصنع غسيل تعدين الذهب

- مشروع الطاقة ppt المتعلقة بالكهرباء

- 500 طن لكل ساعة من خام الحديد كسارة متنقلة

- تهتز مغذيات الصور

- كسارة الكسارة الكلنكر

- كانآلة هينغ الرمال اليابان

- شراء المستخدمة كسارة الغرانيت في الإمارات العربية المتحدة

- الحزام الناقل للبيع في آسيا

- البازلت المحاجر ملموسة

- تكلفة شراء كسارة الحجر الجيري

- عمودي مطحنة الأسطوانة تصميم الأسطوانة

- كسارة الحجر المخروطية

- مورد معدات طحن الكرة في الأردن

- Grinding Stone Flywheel

- Jual Mesin Magnetic Separator Pasir Besi Bekas

- Was Olivine Basalt Used In The Ball Mill In The Early Days Of Mining

- Tantalum Niobium Roller

- Crushing And Screening Machines Prices

- Companies That Make Stone Milling Machine

- Rice Mill Price In Naga City

- Crushing And Grinding Farm Rocks And Stones

- Purpose Of A Coal Mill In Cement Plant

- Crushed Gravel Course

- Hm Hammer Mill For Labotory

- Erators The Mining Witbank Without Experience But Require

- Chinese Fighting Ghanaians In Mining Field

- Crusher Unit In Republic Of Belarus

- Jaw Crusher Adapted