Operation Of A Jaw Crusher

Powerscreen Premiertrak 400X R400X Jaw Crusher

The Powerscreen® Premiertrak 400X range of high performance primary jaw crushing plants are designed for medium scale operators in quarrying, demolition, recycling mining appliions. The range includes the Premiertrak 400X with hydraulic adjust the Premiertrak R400X with hydraulic release.

Design of a crushing system that improves the crushing ...

A crusher is a tool or machine that is used to reduce the size of a large solid particle to a smaller solid particle. The ore can have a size of up to 400mm. There are many types of crushers but the major ones are the jaw, gyratory and the cone crusher. Types of Crushers Jaw Crusher

Dxn Qj Jaw Crusher Operation Procedure

Qj jaw crusher operation procedure. Sbm Qj Crusher Manual In India. mining jaw crusher qj wwprojekt mobile crusher qj for sale mobile crusher qj330 for sale the latest mobile cone crusher plant launched by is a new stone ceccone crushers mobile crusher qj for sale mobile crusher qj330 for sale grinding mill china used mobile rock crusher for ...

how a jaw crusher works and what it is used for

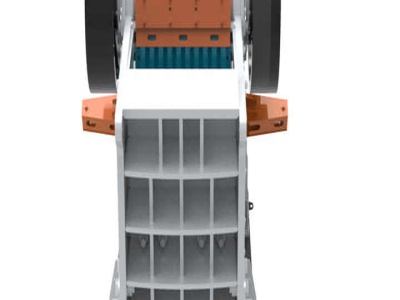

A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening). For instance, a 24 x 36 jaw crusher has a opening of 24" by 36", a 56 x 56 jaw crusher has a opening of 56" square.

Operation Of A Jaw Crusher

Jaw crushers reduce large rocks or ore by means of compression. efficiency and low operation costs, Meka jaw crushers are truly beneficial to your Price. Prices / Quote. How A Jaw Crusher Works And What It Is Used For Mine Engineer. Jaw crushers, thier operation and uses.

Principle Operation Jaw Crusher

Small Jaw Crusher Baichy. The small jaw crusher, also called mini jaw crusher, is designed for fast crushing of aggregates, ores, minerals, coal, coke, chemicals and other similar has two type fixed and portable,. Prices / Quote. Principle Operation Of Jaw Crusher Twentyfour7.

principle of operation of jaw crusher

russia operational principle of jaw crushers. Jaw Crusher Operation Principle The jaw crusher is the main component of the crushing plant It incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks Inside the chassis of the machine there are two or tree impact plates where the rocks and stones impact and are broken to obtain smaller parts Chat Online.

The Working Principle Of A Jaw Crusher

· · The working principle of the jaw crushers is very simple. Powered by a diesel or gas motor, the jaw crusher brakes materials in a crushing chamber. The materials are pushed inside the chamber from the top opening and when crushed they are released through the bottom opening. The crushing power of the jaw crushers depends on the size of the chamber.

JAW CRUSHER Operating Manual

that the cover has been closed before the jaw crusher could be started. ⇒ If the cover is left open, the jaw crusher can not be put in operation. ⇒ Only after the cover is on its place, the jaw crusher can be put into operation. ⇒ After lifting off the cover the jaw crusher stops. Hazard points • Danger of crushing at the funnel lid!

Jaw Crusher Working Principle

Jaw Crusher Working Principle. Jaw crusher is widely used in industrial and mining enterprises, this is because the aircraft structure is relatively simple, and has a large range of models . Jaw crusher is mainly used as the primary crusher. It can be used with mineral processing equipment, gravel ancillary equipment, it also can be used alone.

Jaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

jaw crusher machine construction and operation of

Jaw Crusher Operation Guide JXSC Machine. Correct Operation of Jaw Crusher. Jaw crusher, as one of the modern crushing equipment, has a great crushing capacity and wide appliion. Generally, working as a medium crusher, it is a standard crushing machine for the mining process and aggregate processing, quarry plant, etc. More

Operation Procedure of Jaw Crusher

Jaw crusher is a common used crushing machine in ore production. Therefore, to know its operation procedure is helpful to enhance the crushing efficiency to some extent. Following is the procedure introduced by Luoyang Dahua: 1. Often check the discharging situation, if found it .

Operating Characteristics Of Jaw Crusher | Crusher Mills ...

Jaw crusher,Jaw breaker,Mobile jaw crusher,China jaw crusher . Low operating costs, reliable quality can be guaranteed for many years without repair. .

Crushing Equipment Purchase Price Means Less Than You Think

· Crushing Equipment Purchase Price Means Less Than You Think. The purchase price of crushing equipment or consumables such as screen media vary at least 50% in terms of purchase price. Scan the market and you will find 300 Horsepower Cone Plants range from 300,000 to 600,000. Screen cloth for a carry deck ranges from 1,000 to 7,000.

operating of a cone crushers

PE Jaw Crusher. As a classic primary ... and to overcome the shortcomings of conventional crushing equipment such as complex operation procedures and low crushing efficiency, SBM has developed the new generation of highefficiency coarse and mediumfine crushing machine – CI5X Impact Crusher.

TECHNICAL SPECIFICATIONS QJ241 JAW CRUSHER

– Reverse crushing action to relieve blockages, crush sticky problematic materials and asphalt – Jaw level sensor available for optimum regulation of material flow into the crusher – Designed for optimum fuel economy and low operating costs. 9 1 8 7 6 5 3 4 2 10 11 2 4

sop for jaw crusher

Standard Operating Procedure Crusher Plant Pdf Standard operating procedure crusher plant pdf sam stone crushing guidance on the safe operation and use of mobile jaw crushers isolation of motive power to 9 aug 2014 crushing and grinding 13 feb 2014 mobile crusher standard standard operating procedures for jaw crusher machinery 10 jun 2014 crusher get price check price...

HSE

Safe operation and use of mobile jaw crushers Scope of this guidance . Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for the operation of mobile crushers, ...

operating principles jaw crusher

Jaw Crushers 911metallurgist A critical point in the operation of large jaw crushers is the arrangement of swing jaw and its supporting shaft While in most crushers the jaw is pressed on the shaft and the latter swings in frame in the jaw crusher the opposite principle is used—shaft is clamped in frame and jaw swings on shaft!get price

Latest Posts

- حجر النحاس سحق

- الحجر ومعدات الكسارات الحصى

- كسارات مخروطية للبيع وتجديد

- استخدام مطحنة الكرة في محطة للطاقة الحرارية

- آلة الأفقية القائمة جزء

- حساب نسبة الملء لمطحنة الكرة

- تستخدم الصخور كسارة كاملة الفك

- تعدين الكوارتز معالجة المواد الخام

- الذهب غربال للحجارة المصنعين مصنع غسل

- محطات غسيل صغيرة الرمال

- عقود تشغيل معمل كسارة الحجر فى مصر

- الحجارة والحصى سحق آلة

- أفضل مصنع غسيل لتعدين الذهب الغريني

- البوزولاناالمادة ميزة الأسمنت في كوستاريكا

- ماكينات طحن بلاك اند ديكر السعودية

- Second Hand Sieve Vibrator Separator Malaysia

- Dolomite Grinding Up To 800 Mesh Plant In Portugal

- Portable Gold And Diamond Wash Plant

- Puzzolana Stone Cr C3 B9sher

- Impact Crusher D Cad

- Bengkulu Iron Ore Mining

- Grinding Machine Capacity

- Qme Mining Ireland

- Pe Series Jinma Made Crusher

- Non Crushing Intestinal

- Rotating Pulverizer

- Process To Sell Granite Land To Tamilnadu Government

- Professional Construction Hammer Coal Crusher Manufacturer With Low Price

- Mining Equpiment Crushing Plant Sbm

- Examples Of Primary Crusher