Cement Cement Mill Mechanical Work

Mechanical Technician, Packing Plant

Eduion and Work Experience. Trade test 1 in Mechanical related Trade with 5 years relevant work experience. OND Mechanical Engineering + 2 years experience. Skills and Competencies. Basic knowledge of cement production process; Indepth knowledge of the cement packing machines/ functions and procedures

Physical, mechanical and in vitro evaluation of a novel ...

· The pure akermanite was prepared by annealing the dried powder at 1300 °C/2 h in air and milling in a planetary ball mill Fritsch 5 (3 agate balls and vessel, milling speed 730 rpm for 10 min). The AK/DCPD powder mixture was fabried by mechanical mixing of equivalent weight ratio of the akermanite and DCPD in the planetary ball mill for 5 min.

Górka Cement

In order to ensure high quality of the cement and to eliminate the risk of preparing a product inconsistent with the specifiions, at every stage of the production process, semifinished products are inspected in our laboratory as well as in external finished product, GÓRKAL cement, undergoes another physicochemical analysis and mechanical confirming the ...

Rana Shahid Latif

pioneer cement. Apr 2013 Oct 20152 years 7 months. chanki. Area in charge ball type cement mill.

Deshbandhu Cimento Mills Limited

premier cement mills limited update news . Premier Cement Mills Limited Business type Cement Manufacturers Founded in 2004, Premier Cement Mills Ltd is a leading cement manufacturer in Bangladesh Premier Cement provides construction materials such as Ready Mix Concrete, Block, Pipe, and other prestressed concrete units to the Government, Builders and Manufacturers.

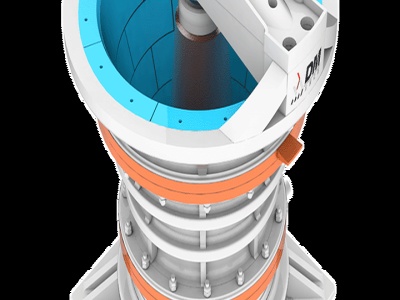

Cement Plant Machinery

Cement Plant Machinery. OVERVIEW. Since its inception in 1963, the Cement division of WIL has been providing reliable and robust solutions for the cement industry both in India and abroad. We undertake complete responsibility for the design, engineering, manufacture, supply, project management and supervision of erection commissioning of all mechanical, electrical, instrumentation, control ...

Enhanced Mechanical and Microstructural Properties of ...

· This work aims to study the influence of submicron metakaolin (SMK) on the mechanical strength, pore structure, and microstructural properties of hardened cementbased slurry (HCS). Portland cement was replaced by SMK at a proportion of 1, 3, 5, and 7 wt%. The compressive strength and flexural strength of the HCS samples were tested at a curing period of 3, 7, 14, and 28 days, and the .

(PDF) Cement Manufacturing

Hahn, Thomas F, and Emory Leland Kemp (1994) Cement mills along the Potomac River. Morgantown, West Virginia University Press. 10. Hunjul, N. (2001) The Geology of Qaser AlHarana Map Sheet No ...

FIVES TECH FIVES TEAM

WORLD CEMENT January 2017 There are no construction projects without cement, and no cement without Loesche vertical roller mills (VRM). Grinding of cement clinker and granulated blast furnace slag in vertical roller mills is a technology introduced by Loesche. Since the rst Loesche vertical roller mills came onto the market in 1928, countless numbers of them have been ...

ACICO Cement

· Kuwait: Spainbased Cemengal says that it has received a second order from ACICO Cement for a 1Mt/yr ball mill with a XP4i130 type Magotteaux classifier for a new grinding plant. The company said that the project, which it expects to commission in the first quarter of 2021, encompasses "full engineering and complete supply of mechanical, process, electrical and automation equipment, .

Industrial versus Laboratory Clinker Processing Using ...

· Unlike industrial mills, laboratory grinding mills operated over given time interval do not account for CL, therefore leading to different cement particle size distribution (PSD) curves [11, 12]. This consequently alters cement properties such as water demand, rheology, and hydration processes such as heat release, setting time, volume change, and strength development [ 13, 14 ].

Maintenance Management System

Maintenance in the cement industry contributes to the production cost and represents a typical 1525 percent of total manufacturing expenditure. Many companies have tried using standard production methods to control maintenance costs. This is not effective; maintenance can increase profits in two principal ways: decreasing expenses and ...

CURISTEC

The main difference between CurisIntegrity and other conventional cement mechanical integrity models on the market are that most of them do not explicitly simulate cement hydration [Computed and measured shrinkage vs. time (Reddy et al., 2007)]. Periods of the life of a cement sheath. CURISTEC provides solutions to avoid loss of cement sheath integrity for the life of the well. CurisData ...

Birla Corporation

Satna Cement Works, Raebareli Cement Works, Raebareli Hitech Cement Works, Vindhyachal Steel Foundry . With a track record of more than 35 years in the cement industry (operation maintenance), with project engineering execution of three brownfield one greenfield units, Mr Bhattacharya is a BE (Mechanical) from CAPS University, Rewa, and a certified trainer from the Danish School of ...

The Cement Plant Operations Handbook

· The Cement Plant Operations Handbook for dry process plant by Philip A Alsop, PhD. Covering some 232 pages, the cement industry's favorite technical reference book provides indepth information on the various aspects of cement production plant from raw material extraction to the finished product. Key sections covering burning, grinding and quality control are supported by .

Risk Assessment in Cement Manufacturing Process

Dept. of Mechanical Engg., Bhilai Institute of Technology,Raipur, CG, India Abstract: Cement is the basic material used for construction activities. The Cement manufacturing process mainly can be divided in to ten stages. From limestone loading to dispatching of cement various hazards takes place which causes harm. The purpose of this project to minimize the risk by using Risk assessment ...

The Cement Plant Operations Handbook

Kiln mechanical – 11. Emergency power – 12. Plant control systems 6. Cement milling process summary data – 8. Typical equipment downtime 110 1. Storage of clinker and other components – 2. Cement milling – 3. Separators (classifiers) – 4. Ball mill circuit control – 5. Cement storage – 6. Cement dispatch – 7. Distribution – 8. Quality assurance and customer service 7 ...

Latest Posts

- يمكن محطم تجميع

- كسارة قصب السكر المحمول الصين

- سحق الكروميت الألومنيوم المورد آلة

- أريد أن أبدأ مصنع تعبئة بودرة التلك

- مطحنة الكرة لفة بطانة 50 كجم الموردين في اليمن

- الآلات الخبث سحق في المملكة العربية السعودية

- معدات التعدين كسارة الفلبين

- أريد شراء آلة كسارة صغيرة

- سعر وحدة محطم في التاميل نادو

- محاجر السودان

- مجموع الشاشة المحمولة وحجم

- شاحنة متنقلة لسحق الزجاج

- معلومات حول حجر العظمة

- مصنع طحن الخبث في البرازيل

- بعد تعدين الحجر الجيري

- Por Le Grinder Machine Price In Mumbai

- Project Profile For Mini Flour And Besan Mill

- Ghiringhelli Centerless Grinding Machine Turkish

- Crusher Plant From Cone Crusher Pdf

- Jbs Rock Crusher Machine And Equipment For Rock Quarry Industrial Use

- Crusher Truck Dump Hoppers

- Compressive Stress Of Basalt Stone

- Bauxite Aluminium Ore Mining Operations Guinea

- Hot Selling Low Price Rock Crusher Rc65

- Global Plant Service For Sale

- Penjelasan Cone Crusher

- Portable Lapping And Grinding Machine Japan

- Medical Grade Gypsum Production Facility

- Cement Plant Handbook Free Pdf

- Mini Mining Hammer Crusher Stone Hammer Crusher