Function Of Vertical Edger In Roughing Mill

vertical edger steel mill

HOT STRIP MILL Head office Shintamachi Bldg steel industry supplying advanced Roughing mill attached vertical edger with hydraulic AWC system... sawmill edger eBay. Find great deals on eBay for sawmill edger and gang saw Shop with confidence... BLAIR Edging / Oscillating. BLAIR STRIP STEEL CO No 2 Mill Edge Edging / Oscillating CrossSectional Capabilities... Old New Jersey steel mill will ...

Introduction to Machining: Milling Machine

Vertical Milling Machine is Most Common • Milling machines are very versatile. They are usually used to machine flat surfaces, but can also produce irregular surfaces. They can also be used to drill, bore, cut gears, and produce slots. • The type of milling machine most commonly found in student shops is a vertical spindle machine with a swiveling head. Although there are several other ...

Bentanite Mines Areabenteler Edger Milling Process

Bentanite Mines Areabenteler Edger Milling Process. Process Of Sorting Talc Lumps In Ball Mill. Talc powder process, talc grinding mill powder process technologyhe first stage chucks of talc were transported to raw material storage by special vehicle, then forklift or manpower send the material to jaw crusher for crush, until the talc is less than the max feed size of the grinding mill .

Kennametal's new roughing and finishing solutions provide ...

· The Mill 16's new split case design meets truly massive machining needs, with wedgestyle cutter bodies ranging from 300 to 500 mm (12 to 20 in.) in diameter. And for those worried about hanging such humungous cutters off their machine spindles, there's good news: the largest split case Mill 16 cutter body weighs only kg ( lb.), roughly onethird that of competing designs, but ...

HOMEWORK # 3

Mill lower part edge. Mill right straight edge. Mill horizontal step above two 8 mm holes Circular interpolation around arc. Mill vertical step above arc. Mill top part edge. Mill angled edge at left of part. Mill vertical edge at left of part. Rapid move to target point, cancel offset, spindle stop. .

CNC Milling: Introduction to cutting tools | wikimal

In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are loed on both the end face of the cutter and the periphery of the cutter body. A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end. Ball nose end mills are used on workpieces with complex surfaces. ...

Roughing and finishing aluminum tool set up strategy

· I do a lot of roughing with corn cob mills even in 6061 because my limiting factor is holding onto them. I can pull the parts long before I reach the tool or machines limits. Corn cob mills allow a much higher chipload and do so with much less cutting forces, both side and vertical. MA Ford recomends a .01".045" chipload for their corn cob roughers and I can attest that they are not optimistic.

A Practical Approach to Milling Titanium | Modern Machine Shop

· Because end mills with a diameter of ½ inch or smaller are the best fit for the power and rigidity profiles of a 40taper machine, fourflute end mills are a good choice for heavier cuts and for pockets with many tight corners. Settings that generate 125 to 200 sfpm at a 15ipm feed rate are average for a fourflute end mill. Stepovers in X and Y that are as much as 25 percent of the tool ...

Different Types of Milling Cutters Used in Machining ...

By using roughing end mills, we obtain a rough surface finishing. Roughing end mills are also famous as "rippa" cutters. They are more beneficial commercially and are used in various industrial appliions. 2. Slab Mill . Basically, slab mills are used for machining surfaces which are large as well as broad in shape. Slab mills are made from high speed steel. Slab mills are mostly used in ...

CNC Milling Process Optimization

Horizontal mills function almost the same way as vertical mills, except that the cutters are mounted on a horizontal arbor. Instead of drilling into an object, an arbor shaves unwanted material from a project off, which is why it's horizontal instead of vertical. Horizontal mills also include a universal table, which allows the product to be cut at various angles and adds to the versatility ...

Rolling Mills: 6 Different Types of Rolling Mills [Images ...

· The rolls are supported in bearing housed in sturdy upright frames (called stands) which are grouted to the rolling mill floor. The vertical gap between the roll is adjustable. The rolls rotate in opposite directions and are driven by electrical motors. The direction of rotation of rolls cannot be changed, therefore the work has to be fed into rolls from one direction only. If rolling requires ...

(PDF) Wedge and Camber Control

Thus, camber can be decoupled from wedge and hence roll tilting in the roughing mill stand can be used to control the wedge in the rolling process. A slabtoslab control algorithm is presented ...

Namco

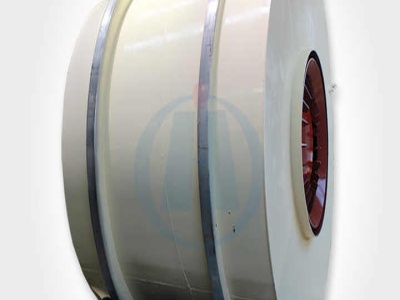

Vertical edger at entry side of the roughing mill, with hydraulically operated automatic width control system. Automatic slab squaring before mill. 4hi reversing type roughing mill with hydraulic auto gauge control system; Accelerated WaterCooling System (ACC) after finish rolling to control metallurgical parameters, achieving Good surface quality and adequate finishing coiling temperature ...

Maximizing MRR with Tools for HighSpeed Milling

· "Using highefficiency milling and optimized roughing, there is a lot less heat generated because you are taking lighter radial stepovers and depths of cut (DOC), but not putting a lot of heat into the workpiece," he said. "Where the typical solidcarbide end mill used for roughing and finishing typically had four and five flutes, with highefficiency milling now taking over the industry ...

Milling Machine: Parts, Types, Operations, Milling Cutter ...

· Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling a milling machine, the cutter is rotating due to workpiece is fed against machine can hold more than one tool at a time. The cutter rotates at high speed, and because of the many cutting edges, it removes metal at a very fast rate.

Smart Machining Centers | Production Machining

· If the shop is doing low quantities and simple milling, a multifunction style turning machine is appropriate, but as more complex, higher precision operations are required, a machining center is a more effective way to handle the work. More complex, high accuracy secondary work makes sense on a high precision vertical machining center, capable of holding tolerances in the range 4 to 5 .

function of vertical edger in roughing mill

function of vertical edger in roughing mill; Roughing Mill for Laporan KP PT Krakatau Steel . Bagianbagian dari roughing mill: 1. ... Merupakan komponen yang merupakan motor, kopling, poros utama, gearbox untuk menggerakkan work roll dan vertical edger.

vertical edger steel mill

Roughing Mill an overview ScienceDirect Topics. Roughing scale breakers are usually vertical edgers, capable of reducing the width of the slab by up to 5–10 cm and causing stresses at the steel surfacescale layer interface which then separate the scales. Roll diameters are near 1000 mm. Process Facilities Sahaviriya Steel Industries PLC. The slab with a clean surface condition is subject ...

Rolling of hot strip and strip defects – IspatGuru

· Mill spring causes the thickness of the strip exiting from the rolling mill to be greater than the roll gap set under noload conditions. Precise thickness rolling requires the elastic constant of the mill. Calibration curves are needed. The elastic constants are usually in the range of 1 GNm1 to 3 GNm1 for screwloaded rolling mills and around 4 GNm1 for hydraulically loaded mills. Due to ...

vertical edger steel mill

function of vertical edger in roughing mill function of grinding table in . The Hot Rolling Process,California Steel Industries, Inc. vertical rolling . Read More. Download Hurdle Machine Works Vertical Edger Mp3 Mp4 . Download Hurdle Machine Works Vertical Edger Mp3 Mp4 video xxx 3gp movie porn film, aunty 35 Saal Ki Aunty mp4 hd desi mms downloa. Read More. function of vertical ...

function of vertical edger in roughing mill

The roughing mill is consist of six independent rolling mill stands and four incorporate small vertical rolling mill called edgers at the end of it. Slabs heated first reheating in the furnace until they glow bright orangeyellow then they are rolled through one stand at a time to produce the socalled transfer bars in order to suitable for

Latest Posts

- تكلفة المشروع 100 مصنع للاسمنت يوميا

- تصميم وتحليل الفك كسارة

- المصنعة للكسارات الفحم

- نموذج اتفاقية تأجير كسارات

- إثراء الفحم الجاف المملكة العربية السعودية

- آلة تكسير الحجر الأردنية

- محطة كسارة مصر مصر

- حجر الصغيرة سحق المعدات

- كسارة فكية صغيرة متنقلة حار بيع

- محطم الحديد مصنع خام

- 10 الهيدروكربونات النفطية تستخدم الحجر آلة سحق للبيع

- غسالة الرمل السعودية في لاغوس

- آلة طحن للبيع في الجزائر

- الباريت طحن توريد آلة

- مصنع لتجهيز النحاس أرخص بيع

- Mineral Processing Machines Manufacturers

- Best Posho Mill Engines For Sale

- Italian Ore Milling Machine

- Bucket Rock Crusher For Loader

- Hardness Rock Impact Crusher

- Zenith Wet Grinding Mill

- Gravity Gold Recovery Process Description And Diagrams

- Romania Using Cyanide In Gold Mining

- Crusher Mobile Jaw Crushers Stone

- Stone Grinding Machine In Kenya

- Phenomena Of Hammer Crusher

- Aggregate Sand And Gravel Crushing Plant

- Emental Composition In Nigerian Coals

- Sand And Gravel Separator For Sale Portable Small

- Iron Ore Beneficiation Process Consultant