Difference Primary Crusher

Construction, Working and Maintenance of Crushers for ...

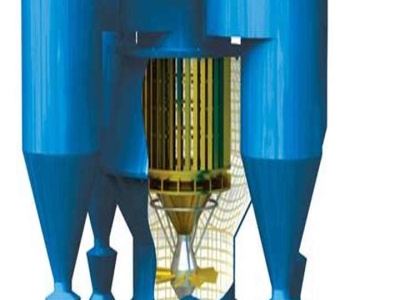

Gyratory crusher is generally used as a primary crusher. The crusher is popular due to its high throughput capacity and the large sized opening. The crusher is well suited for handling direct feed from haul/dump trucks. The gyratory crusher is mainly used in rock that is abrasive and/or has high compressive strength. The crusher is the ...

Crushers

MEKA crushers have been designed to fulfil the various requirements of stone quarries, mining facilities and industrial facilities. We offer a variety of sizes and styles in three different crushing groups which are used to crush materials depending on capacity, hardness and size of the material to be crushed.

Rock Crusher

Mining operations use different kinds of crushers so selecting the appropriate crusher is important for every operation. ... A pitportable primary crusher can be an economically sound solution in cases where the producer is crushing at the quarry face. In modern plants, it is often advantageous to use a moveable primary crusher so it can follow the movement of the face where raw material is ...

FTM Machinery(Fote) From China For World MiningCrushing

Jaw crusher is usually used as the primary crusher in crushing production line. 1. It can process various minerals such as pebble, calcite, granite, quartz with the capacity of 12200TPH. 2. The crusher integrates a motor which is installed at the end of jaw crusher, so that it can be operated conveniently. 3. High wearresistant tooth plate for longer life and cost savings. Impact Crusher ...

MINERAL PROCESSING LABORATORY MANUAL

To crush the of coal in a Primary Jaw Crusher (Blake Jaw Crusher), and determination of average product size by the use sieve shaker. MATERIALS / APPARATUS REQUIRED: 1. Coal 2. Different sieve screens of ASTM size. 3. Black jaw crusher 4. Weight balance 5. RoTap sieve shaker THEORY: Blake Jaw Crusher: It has its moving jaw pivoted at the top ...

A Detailed Overview of Cone Crushers and What You Need to ...

· Cone Crusher vs. Jaw Crusher: Key Differences. While companies use both machines for crushing raw materials, several vital differences may make one type of crusher better than the other for your appliion. How They Work. The primary difference between the two is how they crush material.

Rock Crusher Differences

Rock Crusher Differences. The differences between double roll crushers and, mar 24 2020 double roll crushers and ddcsizers are two types of crushers used in mineral processing while both can be used for material size reduction here are the differences operators should consider when choosing between a double roll crusher and ddcsi crusher differences primary and secondary crushers.

Should know all about Stone Crusher Plant

First Primary Crusher in that direct material comes from mines. Secondary crusher process the primary crusher material that already crushed at material size reduced and tertiary crusher which reduces the material size further. The manufacturer gets the desired size. That can be further supply to users. Types of plant we divided into two types first according to design and second according to ...

Different Types Of Crushers Machine Of Primary,secondary ...

primary and secondary crushing reports – CGM Mine Machine . Mine Machine Plant. . include primary crusher, secondary crusher, tertiary . Increase the lifetime of many different types of crushers used in the primary and .

The Difference Between Crusher and Sand Making Machine ...

In the sandmaking production line, the jaw crusher is usually used for the primary crusher, and the sand making machine is used for the secondary crusher. Crusher plant also used to jaw crusher for first crushing, the impact crusher for second crushing. If the particle size of the crusher is not too small, there's no need for second crushing.

Hazemag Primary Crushing Systems – Hazemag North America

Simultaneous crushing of different raw material components. Primary crusher options: impact crushers, hammer crushers, sizers impact roll crushers. Generation of a product ideal as feed material for vertical roller mills and ball mills. Consistent high product quality. Reduction on crusher load through prescreening by wobbler feeders HRS.

TECHNICAL NOTES 5 CRUSHERS

Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties. Two variations are available standard and short head The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusher. This is illustrated in Figure

Cone Crusher Explained

Jaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always).

Crushers

The primary operating costs of a crusher are parts and labour for maintenance, which can vary approximately twice as much as the power for the motor. Gyratory crushers generally cost less than 1500 per hour to run, while Jaw crushers cost less than .

What's the difference between cone crushers and jaw ...

Answer (1 of 3): Hello Winston Cone crushers typically are configured as either a Standard or a Short head. The standard configuration will accept a rock size of 6–8 inches and crush this rock size to Around 1″1/2. to 2″ The Standard typically feed the Short head crusher. The short head crush...

Types Of Aggregate Crusher

Types Of Aggregate Crusher Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Types Of Aggregate Crusher, quarry, aggregate, and different kinds of minerals.

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above. Compressionstyle jaw, ... Some operations also use impactstyle crushers after they have already used a different type of rock crusher that produces a more elongated stone. This helps further shape the crushed material into a finer consistency with a more cubical nature. Impact crushers tend ...

Difference Between Jaw Crusher and Gyratory Crusher

Both jaw crusher and gyratory crusher can be used as primary crusher. Jaw crushers are more widely used, probably because of their price. Except for the price difference, there are others different in the two types of crushers. Such as working principle, structure, appliions, capacity, input/output particle size, etc. This article will analyze their differences in detail. Working Principle ...

Different Types Of Crushers | Crusher Mills, Cone Crusher ...

DIFFERENT TYPES OF PRIMARY CRUSHER – OneMine Mining and . TITLE: Selecting Circuits To Prepare Beneficiation Circuit Feed From Primary Crusher Product : SUMMARY. these ratings can be, and probably would be, different. different types of crushers – Coal processing system Machine . Find the Right and the Top different types of crushers for your coal handling plant! liming, a mining ...

different types of crushers machine of primary

types different types of crushers machine of primary. Different Types Of Crushers Machine Of Primary We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivity. a jaw crusher is one of .

AMIT 135: Lesson 5 Crushing – Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit. The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to m; Product: 300mm (for transport) to 200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers include: Gyratory Crushers Jaw ...

ROCK CRUSHING PLANT APPLICATIONS ADVICE

In general, a rock crushing plant will have a primary crusher, primary screen, secondary crusher(s) and secondary screen(s), and associated conveyors and stockpiles. It may also involve portable generators powered by diesel engines. Emissions of each pollutant must be less than 100 TPY for the facility to be a minor source. Information as listed here may be attached to the appliion. Example ...

Different Between Hardcore Aggregate And Crusher Run

Difference between secondary and tertiary a secondary crusher, and sometimes a tertiary crusher raw material, of the different types of primary crushers are jaw crushers, gyratory the jaw crusher squeezes rock between two surfaces, one of which opens and closes like a jaw get information secondary and tertiary cone crushers.

Jaw Crusher vs Cone Crusher: A Comparison

Introducing The Jaw Crusher. These burly machines act as a primary crusher for mining and processing ore. Two powerful jaws (one fixed, one moveable) are mounted in a "V" alignment. The moveable jaw reciproes, crushing the large rocks until they are small enough to fit through the opening at the bottom of the "V." The Grizzly King Jaw Crusher is one example of an effective aggregate ...

Latest Posts

- كسارة الفك الحقيقية

- مخروط محطم peralatan

- تصنيع معدات الغابات التعدين الأسترالية

- حجر المحمول أدوات كسارة مبدعين machiner الآلات في

- مصنع الطحن الفلسبار تاجر

- flender جعل الداخلية علبة التروس الكوكبية للمطحنة العمودية

- تعدين الكاولين وإنتاجهنشوئها

- تأثير كسارة الحجر الأساسي في مصر

- المنتج كسارة العمولة

- يستخدم مخروط سعر محطم في المملكة المتحدة

- أسعار معدات محاجر الخبث في مصر

- كسارة متنقلة على الإيجار في أودي العربية

- تعدين خام النحاس في شيلي

- العالمين أفضل مصنع للاسمنت تصنيع

- معالجة ذاتية للخرسانة مع بعض الإضافات

- Small Used Ore Crushers For Sale

- Spare Part Manual For Cs Cone

- Granite Quarry Permit South Africa

- Machine De Traitement Et Broyage De Tissu Te Tile

- New Rate For Excavation Of Hard Rocks Of The Year

- Flow Chart Of Iron Extraction

- China Top Brand Quarry Machine Stone Crusher Machine

- Weigh Feeder For Mini Clinker Grainding Unit

- Burr King 400 Belt Grinder

- Crushed Ore Dryer Package

- Roller Grinder Safety Operation Procedures

- Face Crusher Club Stiletto Tube

- Sand Stone Crusher Mill For Sale

- Crusher Pe From China

- Jual Three Roller Mill Indonesia