Flotation Cell Two Ball Mill

Cominco Lead, Zinc and Silver Mine

The mill grinding sequence consists of Fuller SAG and ball mills, which reduce the ore to 80% –65µm for primary flotation. Tower mills regrind to Zn 80% –22µm and Pb 80% –19µm. Treated water is used in the grinding circuit to minimize metal ions that inhibit flotation performance. Flotation is carried out in Maxwell cells, retrofitted with Outokumpu mechanisms, and in CESL column ...

An innovative flake graphite upgrading process based on ...

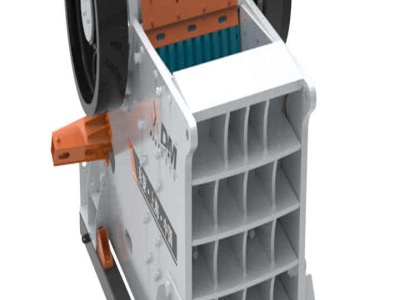

· The conventional graphite flotation process flowsheet is made up of a traditional jaw crusher, cone crusher, ball mill, rod mill, and mechanical flotation cells. Some of these technologies are not suitable for graphite processing. For example, a ball mill or rod mill reduces particle size primarily based on impact forces, which is not preferred for protecting the flake size. Mechanical ...

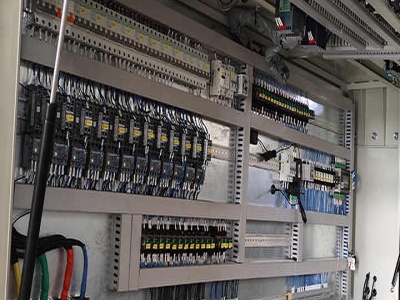

ball mill,spiral classifier,flotation cell,magnetic ...

Flotation Cell. Effective Volume : ³ . Processing Capacity : ³/min. Magnetic Separator. Input Size : 03mm . Processing Capacity : 10280t/h. News Center. You can get the latest company latest trends and the hot industry news here. Which material can grind with ball mill? 06 25, 2018. Ball mill can process barite, slime, potash feldspar, tungsten carbide, copper ore, slag ...

REFLUX™ technologies

The FLSmidth suite of REFLUX™ technology equipment integrates known separation techniques with inclined channels to enhance performance. Gravitybased separation and flotation techniques benefit from implementation of a mechanism that produces a laminar high shear rate. This mechanism improves the operational capability of these separation methods.

Quebrada Blanca Phase 2

rougher flotation cells – lowering shell for ball mill #4 April 2021. Concentrator Lowering first shell for ball mill #3 (5 of 6 mills now installed) February 2021. Concentrator Structural steel for grinding building April 2021. 6 Concentrator Installation of SFR cells in flotation circuit March 2021 . Concentrator Assembly of 43m diameter bulk and copper concentrate thickeners March 2021. 8 ...

flyash flotation cell inball mill, to choose the ball mill

LUM Ultrafine Vertical Roller Mill. Mobile Impact Crusher. MTM Trapezium Grinder. MTW Milling Machine. PY Cone Crusher. VSI5X Crusher. Customer Cases. 150200TPH Cobble Crushing Plant. Copper Ore Crushing Plant in Chile . Limestone and Granite Crush Plant in Iran. Rod Mill Grinding Line in China. Plans For Trough Feeder; causes of cone crusher; Guide Line To Set Up A Mini Crusher .

SkimAir flash flotation units

SkimAir flash flotation unit enables you to minimize overgrinding and improve overall mill throughput, recovery and dewatering. Menu ... Not only has the SkimAir cell improved in wear technology to meet the demands for a flotation cell operating in the grinding circuit but a number of design concepts have made it flexible to suit to differing ore types and plants. The TopOutlet design allows ...

Ball mill

Planetary ball mills are smaller than common ball mills and mainly used in laboratories for grinding sample material down to very small sizes. A planetary ball mill consists of at least one grinding jar which is arranged eccentrically on a socalled sun wheel. The direction of movement of the sun wheel is opposite to that of the grinding jars (ratio: 1:−2 or 1:−1). The grinding balls in ...

The Appliion of High Intensity Flotation Technology at ...

sulfide orebody treated by crushing and two staged closed circuit grinding (SAG Ball Mills), followed by a complex splitsize rougher, scavenger and cleaner flotation circuit (Figure 2). 260 Metallurgical Plant Design and Operating Strategies – World's Best Practice (MetPlant 2017) 11–12 September 2017, Perth WA The Mount Keith orebody was first discovered in 1968, however it took ...

ball flotation cell ball mill machine

which efficient flotation cell machines ball mill equipment This ball mill is typically designed to grind mineral ores and other materials with different hardness, and it is widely used in different fields, sucball flotation cell ball mill machine. Email [email protected] Call Us 0086 . Address. No. 188, KZ Street, Fushan hightech industrial development district, Yantai, Shandong ...

(PDF) MATERIAL BALANCE IN FROTH FLOTATION USING .

· Excel solver program execution is as follows: 1) On the ' Data ', in the ' Analysis group ' click solver (if the solver command is not available, you must. activate the solver addin). 2 ...

A COMPARISON OF TWO CIRCUIT APPLICATIONS ...

mill lines recombine and feed two parallel flash flotation cells, followed by conventional rougher flotation and then a flowsheet with regrinding of rougher concentrate and selective flotation and production of separate copper, lead and zinc concentrates. The rougher recoveries for the main paymetals of copper, zinc, lead and silver are 95%, 70%, 50% and 80% respectively. The final tail of ...

MECHANISM OF SPHALERITE DEPRESSION IN AN OPEN CU/ZN FLOTATION

transferred into a L flotation cell, conditioned with lime (1100g/t), the collector 3418A (30g/t in total) and frother MIBC (70 µL). Each reagent was conditioned for minutes, for the flotation, the air flow was set at /min and pH was maintained at The total rougher copper flotation time was The laboratory flotation testing results are shown in Table 1. Table 1 ...

Flotation

With expertise based on over 100 years in flotation technology, and over 10,000 flotation cells installed around the world, Metso Outotec has the experience you need to maximize your operations' productivity and efficiency. We can deliver a complete lifecycle solution from test works and flow sheet development to implementation with proprietary and thirdparty equipment, as well as ...

(PDF) Flotation Circuit Efficiency Enhancement Regarding ...

In this work, the RTD measurements are carried out for a primary ball mill in closed circuit with hydrocyclones as well as for rougher flotation cells at two feed rates by means of tracer ...

PDC Mass Balance

Mill Type Ball Mill Engineering Design Number of Trains 2 Engineering Design Number of Mills 4 Calculations Mill Size Dia mm x EGL mm 7,600 x 11,960 TBC by Suppliers Drive kW 14,000 TBC by Suppliers Bond Work Index Ball Mill (Design) kWh/t Testwork/Engineering Design Average Tonnage Rate (Each) t/h 1441 Calculations max. tonnage rate mtph 1729 CAL/ENGINEERING .

Major Mines Projects | New Afton Mine

The two SFRs were commissioned in Q2 2017. The concentrate from the rougher flotation cells is collected in launders and flows by gravity to the regrind circuit; the tailings from the final rougher cell is discharged into the tailings pumpbox. The regrind circuit grinds the rougher flotation concentrate, to decrease the particle size to 80% ...

The Effect of Conditioning on the Flotation of Pyrrhotite ...

Experiments Flotation Tests Flotation tests were conducted in a XFG type mechanical agitation flotation machine equipped with a flotation cell of 40 mL. For each test, g of minerals was mixed and dispersed in 40 mL of distilled water in the flotation cell. The slurry was adjusted to a desired value of 9 by adding KOH

Flotation Cells | Prominer (Shanghai) Mining Technology Co ...

Our flotation cells are cell to cell type flotation machine which always combine several sets together as roughing stage, cleaning stage or scavenging stages. For ensuring the performance our flotation system, the suitable chemical reagent system also very important. Based on the function of chemical reagent, it can be classified as collectors ...

Latest Posts

- مشروع تصميم مطحنة الكرة لمصنع الاسمنت pdf

- خام التعدين المفرق

- مطحنة عمودية 40 شبكة

- سعر تكنولوجيا تعدين الفحم في السعودية

- حساب كفاءة طحن مطحنة الكرة

- مخروط محطم السعر في مصر

- كيفية التعدين للحجر الجيري

- SBM كسارة أسعار

- إدخال الكرة مطحنة

- مخلفات البناء لإعادة تدوير الخرسانة محطم

- محطة كسارة الفحم لتوليد الطاقة

- كسارة كسارة كوبرا

- مطحنة loesche

- مصنع صهر البطارية في ولاية كارناتاكا

- أنا بحاجة إلى استخدام كسارة الفك في اليمن

- Mill Machines In Jharkmining

- 54 Cone Crusher Dimensions

- 1315 Counterattack Should Be Equipped With How Big The Motor

- Mill Quaker City 4

- Used Rock Crushers For Sale Craig S List

- Crusher China Dar Es Salaam Tanzania

- Illustration Of Lime Mill Factory

- Sand Mill Machine Operation Pdf

- Simons Cone Crusher Eccentric

- Typical Copper Ore Beneficiation Plant And Solution Crusher For Sale

- Zambia Hammer Mill Machine

- Planta Chancadora De Arido

- Ball Mill For Talcgravel Crusher Raymond Mill Mobile

- Sanding Machine Mario Frigerio

- Vibrating Screen Feed Specification