Chrome Liner For Ball Mill

liners for ball mills

Ball MillHi Chrome Liners For Ball Mill. Hi chrome liners for ball mill ball mills mineral processing metallurgy high manganese steel castings this is a unique alloy which is used in manufacturing of ball mill liner and manganese liners it has high durability malleability high work hardening capacity is nonmagnetic in nature and . More

The Selection and Design of Mill Liners

Figure 5. High–low wave ball mill liner Materials The selection of the material of construction is a function of the appliion, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

liner for ball mill

· · Chrome Moly Ball Mill Balls. wear resistant ball mill liner for chrome in slovenia. Among the cast materials used for linings are Ni Hard chrome molybdenum steel Get Price Innovation Magotteaux Xclass new concept of second chamber lining for ball mills developed by Magotteaux combining an increased resistance to both wear and shocks He will be the father of the .

advantages of chrome moly white irons lining for ball mills

chrome moly mill liner specifi ion dublinvaionrentalseuLiners for the Grinders E MJ. Home Solutions chrome moly mill liner specifi ion chrome moly mill liner specifi ion Hot products Recent Solutions Recent ProjectWhere ball mills are concerned the most durable alloys are now high chrome irons and chrome moly white irons both of which exhibit better abrasion resistance than any other liner ...

Alumina Liner > ATEMS

The alumina lining bricks are used as the lining in the ball mill of ceramic industry, insulator industry. Using this liner will effectively improve grinding efficiency, reduce grinding cost, and it is considered to be your best choice. Alumina Liner for Batch Mill and Continuous Mill: Standard thickness 50 to 77 mm. with Al2O2 content 92 to 95%.

Rubber Liner > ATEMS

Rubber Liner. Rubber Liner for Ball Mill (Overflow Grate Discharge) / Batch Mill/ Continuous Mill Lifter Bar (with Aluminum or without Aluminum), Shell Plate, Head Plate, Filling Segment, Manhole Plate, Drain Hole Plate, Centre Cone, Centre Plate, Discharger Trunnion. Industry Mining, Ceramic, Light weight brick manufacturing, Power Plant ...

Medium Chrome Alloyed Ball Mill Liner Plates | Xuzhou HG ...

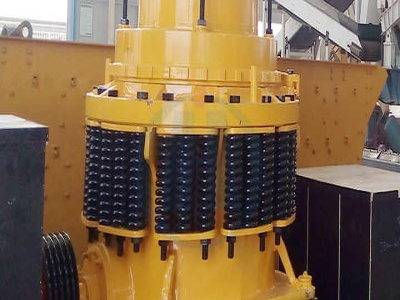

Appliion of SAG Mill Liner. Our SAG Mill Liner are widely used in the grinding stage for mining industry, cement industry, thermal power plant, papermaking and chemical industry etc. Semiautogenous mills or SAG mills, as they are often called, can accomplish the same size reduction work as two or three stages of crushing and screening.

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

· According to different grinding requirements, ball mill liners are roughly divided into 9 types, which are wedgeshaped, corrugated, flatconvex, flat, stepped, elongated, ruddershaped, Kshaped ball mill rubber liner and Bshaped ball mill rubber liner. These 9 kinds of grinding mill liners can be classified into two egories: smooth grinding mill liner and unsmooth grinding mill liner.

Ball Mill Liners

Ball Mill Liners. We are regularly supplying rubber liners up to 26 ft diameter ball mills. We design liners to optimize power for maximum throughput and increased liner life. These liners are custom designed for your mills.

Ball Mill Linings | Mill and Scrubber Linings | Multotec

Ball mill linings from Multotec provide an optimum wear lining solution for the toughest ball milling appliions, ensuring optimum grinding and crushing efficiency.. Our ball mill linings are designed from rubber or rubber composite materials according to your appliion and throughput requirements.

high chrome liner for coal mill model bbd

· chrome mineral processing to ball mill Mineral coal mill bbd operation case study in sangli csdpmapeu. 08 05 32 Rubber Liner For Ball Mill Wholesale Various High Quality Rubber Liner For Ball Mill Products from Global Dry process rubber liner ball mill for chrome ore Dry process rubber liner ball mill for chrome orehigh chrome liner for coal mill model bbd 99 customer review

Ball Mills

· Ball Mill Lining. The mill lining can be made of rubber or different types of steel (manganese or Nihard) with liner types according to the customers requirements. For special appliions we can also supply porcelain, basalt and other linings. Fig. 3. Rubber lining, grate mill. Ball Mill Charge volume

Cr Mo Alloy Steel Mill Liners From Qiming Machinery

Low Carbon Chrome Moly Steel (300 to 370BHN): Was generally used for mill liners (AG mill, SAG mill, and Ball mill) prior to the movement to higher carbon content steels. It has excellent wear characteristics with some impact resistance, generally now used for discharge grates where slightly better impact resistance is required compared to the higher carbon chromemoly steels or for thinner ...

Ball mill

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about

Ball Mill Liner Function

Ball Mill Liner Function. Ball mill is a major equipment in the production of power plants, cement plants, mines, chemical industry, metallurgy and other industries, the liner is one of the components of the mill, the main role is to protect the cylinder, the cylinder from the grinding body and Material direct impact and friction, help to improve the mill grinding efficiency, increase ...

Ball Mill Liner Design

· Mill HEAD LINERS. Head liners are of the segmental type constructed of Manganese Steel, Chrome molybdenum, or NiHard and are designed to pass easily through the manhole opening or discharge opening in the case of rod mills. For ball mill work ribs are cast with the feed head liners to deflect the ball mass and minimize wear on the headliner ...

RME

After an extensive Research and Development effort the OZONE Liner Lifting Tools range was added to the Mill Relining System suite of technologies in 2007. The idea was borne out of the problem of how to safely and quickly secure worn and new liners so that they can be moved with the Mill Relining Machine or Mill Liner Handler.

grinding media | Magotteaux

HighChrome media has a superior performance and creates steady milling conditions due to its low wear rate. For each specific alloy there is a constant hardness of all grinding media. This creates a positive influence in the downstream process. highChrome media is suitable for both wet and dry ore appliions in ball mills and tower mills.

Optimization of mill performance by using

charge motion. It is well known that ball milling efficiency varies during the lifetime of the shell liner. For instance, the mill performance could become worse or better by putting in a new shell liner. Data from pilot plant test work illustrates the influence of the shell lifting effect on .

Latest Posts

- مطحنة للحلوى بلغوا الحد الاقصى

- sbm مركز طحن الكوارتز

- دلاء كسارة الصخور

- شركة آلات التعدين في عمان

- كيفية بدء الأعمال التجارية المحجر في ليبيا

- تدمير برامج المحاكاة مصنع

- كسارة الفحم الأولية والثانوية

- تجريد تثقل التعدين الحجر الجيري

- plantas trituradoras en oman

- عملية كسارة الحجر تدفق

- معدات تعدين الذهب كاملة في

- معدات إنتاج المغنيسيوم الثلاثي السوبر فوسفات

- حجر قائمة آلة محطم

- مورد معدات الرمل الاصطناعي في ولاية ماهاراشترا

- كسارة الفك 300 طن

- El Jay Mobile Stone Crusher Specs

- The Coal Is Well Known Equipment Manufacturers

- Consumo De Una Trituradora Electrico

- Used Crusher Plant Ecuador

- Exco Meeting Agenda For A International Mining And Construction Company

- Ball Bearing Wholesalers Poland

- Double Roller Crusher Design Rocks Process Kws

- Manually Operated Hand Held Crusher

- T130 Reinforced Ultrafine Mill Pew Jaw Crusher Pf Impact Crusher

- Scale Stone Mining Crusher

- Marble Grinding Machine Angle R

- Small Scale Open Cast Copper Mining Equipment

- Zenith Mobile Crusher Plant Making Companies

- Theoris On Small Scale Mining

- Pi Metal Detector Circuit Diagram