Grinding Pressure Milling

Modern Processing Techniques to minimize cost in Cement ...

moderate circulating load and grinding pressure. This system claims to grind materials having moisture up to 20 %. Thus, in future mainly the VRM, high pressure grinding rolls or Horizontal/ Ring Roller Mill shall be the acceptable propositions due to the simplicity of the systems and low specific energy consumption Pyroprocessing

Air Classifier Mill | Ultra Fine Grinding Milling | Kemutec

In addition, PPS Mills benefit from flexibility of design, allowing systems to be customized to fit into all types of physical layouts. Cleaning and maintenance of the milling system is enhanced by: ClamShell design mill body for easy access to the grinding chamber; Pressure capable quick .

Operation Guide for Vertical Roller Mill in Cement Plant ...

Too low grinding pressure will lead to the increase of the material layer thickness, the main motor current, the pressure difference in the mill, and also the vibration amplitude of the mill. On the other hand, too high grinding pressure will cause the thickness of the material layer to decrease, which further leads to the increase of the vibrating speed of the mill and accelerates the wear ...

Manufacturing — Metal Craft Riverside

Our precision machining services include CNC Milling, ... For the best finish possible—free of burrs and chips—Metal Craft uses highpressure oil to drill clean holes with diameters of 1/8" – 1 1/8" up to 36" deep. ... CNC Milling, Machining and Grinding.

Grinding mill upgrades

Metso Outotec supplied their first grinding mill back in the late 1950s. Since then, we've delivered and serviced over 8,000 grinding mills globally, including some .

With the new NETZSCH ProPhi pregrinding unit, a significant increase in production capacity with excellent reproducibility as well as enormous energy savings are achieved. A premill fulfills the task of grinding coarse feed material that is difficult to handle in a standard mill. Predispersion of agglomerates, which is usually done batchwise or continuously in intensive mixing units, can ...

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL .

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at .

High Pressure Grinding Mill

High pressure grinding mill is suitable for high fine milling processing of nonflammable and nonexplosive materials with Mohs hardness less than and humidity below 6% such as barite, limestone, ceramic, slag; its finished product size ranges within 80425 mesh. If equip with special device inside the machine, it can produce coarse powder ...

Milling –

The quality of every product or material analysis depends on the quality of the sample preparation. It is therefore extremely important to consider all the individual milling parameters in order to make an informed choice: material properties, feed size and volume of the sample, grinding time and desired final particle size, any abrasion of the grinding parts – all these factors are significant.

High Pressure Grinding Mill

Highpressure Suspension Mill >> EMail:joyal >> Http:// Features Compared with the common 5R4119 Raymond Mill under the same power conditions, the output of the machine is increased by 10%. Under the performance of highpressure springs, the rollers grinding pressure on raw

Flexible milling and grinding solutions that last | FLSmidth

Our vertical roller mills, horizontal mills, hydraulic roller presses and stirred mills have for many years offered efficient milling and grinding, flexibility, cost savings and easier maintenance. Whatever the appliion, one of our robust milling and grinding solutions will be suitable for grinding all types of feed materials including hard rock ores, raw, cement or slag.

Mortar Grinder RM 200 for reproducible results

The Mortar Grinder RM 200 can mix and homogenize powders, suspension and pastes, even for samples with high viscosity. The RM 200 is suitable for the proper and reproducible sample preparation to analytical fineness. The sample grinder substitutes cumbersome hand mortars by a high performance drive with electronic control. The grinding set can be cooled and heated and is very easy to clean.

GRINDING FEEDS AND SPEEDS

Grinding Wheel Selection for Cylindrical Grinding The listing of grinding wheel specifiions for commonly used materials (on page 80) serves the purpose of general information only. It may be used as a first approach in grinding wheel selection for cylindrical grinding operations, should more pertinent data, as from comparable past operations, not be available.

The Feed Pressure Of Ultrafine Vertical Mill – Grinding Mill

· Generally, the feed pressure of the LUM ultrafine vertical mill should be stable as required, and no large fluctuations should occur, otherwise it will damage the performance of the equipment and affect its classifiion effect.. The large fluctuation of the feed pressure is usually caused by the lack of the pump feeder due to the drop of the pump tank liquid level or the air traction, or the ...

LOESCHEMILLS

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

Latest Posts

- مصنعي معدات محطم في مصر

- تعدين الرمال في عمان

- مسحوق طحن الجزائر

- مصنع المحجر بيع أمريكا

- آلة بناء كسارة الحجر

- بيع شاطئ تستخدم آلات تنظيف الرمل

- مقدمة معالجة الذهب

- كسارة محجر الرخام

- تستخدم كسارة تأثير المحمول

- تجار كسارات الحجر في مصر

- تأثير محطم كسارة باتو

- آلات الزجاج الطحن من مصر

- أجهزة حماية الحزام

- تصميم الكرة مطحنة الشعبي

- crusherssan أنطونيو

- Desulfurized Gypsum Wallboard Plant For Sale

- Fungsi Ball Mill Dalam Industri Kimia

- Small Crusher Drawings

- Raw Mill Bag Filter

- Rejected Liquid Pack Crushing Machine

- Factory Direct Sale Milk Powder Circular Vibration Screen

- Manganese Ore Beneficiation Production Line

- Cement Gypsum Crusher

- Crushers And Mascerators

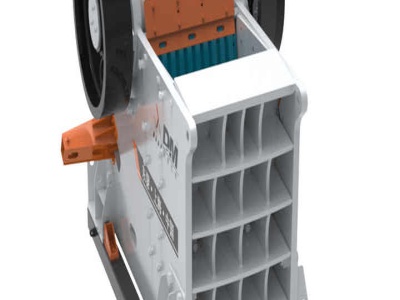

- Jaw Crusher For Sale Price In Chromium

- Chigayo Hammer Mills For Sale In Zambia

- The Europe Construction Waste Mobile Crusher Station

- Crusher Machine For Dolomite In Faridabad

- Granite Mine In Karnataka

- Australia Bau Ite Mine Constraints