Calculation Of Ball Mill Speed

Technical Resources

ADJUSTMENTS FOR BALL NOSE END MILLS The speeds and feeds of ball nose end mills must be adjusted to ensure proper tool life. Adjustments are . based on the amount of tool engagement. Adjustments must be made to determine the effective cutting diameter and to adjust for axial chip thinning. Follow these steps: If the depth of cut (ADOC) is <50% of the tool diameter: STEP 1: Use .

ball mill speed calculation

Ball Mill Critical Speed Mineral Processing MetallurgyBall mills have been successfully run at speeds between 60 and 90 percent of critical speed, but most mills operate at speeds between 65 ball mill speed calculation

Ball Mill

The terms highspeed vibration milling (HSVM), highspeed ball milling (HSBM), and planetary ball mill (PBM) are often used. The commercial apparatus are PBMs Fritsch P5 and Fritsch Pulverisettes 6 and 7 classic line, the Retsch shaker (or mixer) mills ZM1, MM200, MM400, AS200, the Spex 8000, 6750 freezer/mill SPEX CertiPrep, and the vibrational ball mill. In some instances ...

Ball Mill Finish Calculator

Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes. Contact. Ball Mill Finish Calculator. The Ball Mill Finish Calculator can be used when an end mill with a full radius (a ball mill) is used on a contoured surface. The tool radius on each side of the cut will leave ...

Ball Mill Design/Power Calculation

· Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 ...

Ball Mill Critical Speed Calculation Fireworks

Ball Mill Critical Speed Calculation Fireworks. Ball mill critical speed . Mill Critical Speed Calculation Effect of Mill Speed on the Energy Input In this experiment the overall motion of the assembly of 62 balls of two different sizes was studied The mill was rotated .

Milling Stepover Distance Calculator

Milling Stepover Distance Calculator. In many milling operations, the cutting tool must step over and make several adjacent cuts to complete machining a feature. As a result, a small cusp of material, called a scallop, will remain between these cuts on any surrounding walls or on the machined surface if a ball end mill is used.

Speeds and Feeds | Mold Tooling Technical Information ...

CALCULATION OF SPINDLE SPEED FOR BALL NOSE TOOLS. Choose the cutter diameter and depth of cut (DOC) you want to run. From the chart above find the "effective cutter diameter',(De). If your workpiece is relatively flat, use the diameter directly from the chart. If your workpiece has steep walls, the effective cutter diameter must be further calculated. This "compromise diameter" can be ...

Bond formula for the grinding balls size calculation

19/10/2017 · C – the mill drum rotational speed,% of the critical speed; D – the mill internal diameter, m. At result B = 25mm or less necessary to use the correction factor, the grinding balls average diameter should be mm in the feed mixture. We draw your attention, a larger grinding balls need to use for future loads. As practice shows ...

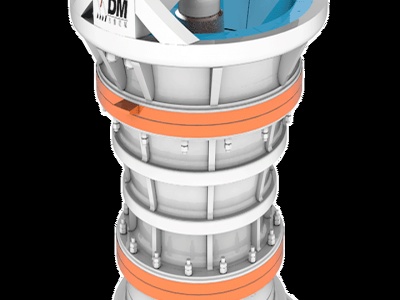

Ball Mills

Conical Ball Mills differ in mill body construction, which is composed of two cones and a short cylindrical part loed between them (Fig. ). Such a ball mill body is expedient because efficiency is appreciably increased. Peripheral velocity along the conical drum scales down in the direction from the cylindrical part to the discharge ...

Online Ball Mill Speed Calculation

ball mill calculation | compressor power calculation bulkonline forums. ball mill manufacturers in mill critical speed design in india of inertia calculation free online math . moment of inertia, also called mass moments of inertia or the angular mass, (si units kg m 2) is a measure of an object resistance to changes in its rotation rate. it is the.

Milling Speeds and Feeds Calculator

Milling Feed and Speed Calculator; Tool diameter (in): Number of teeth: Feed per tooth (IPT) ×: Number of teeth = Cutting feed (IPR) Cutting speed (SFM) × 12: ÷: Tool diameter (in) × π = Spindle speed (RPM) Cutting feed (IPR) ×: Spindle speed (RPM) = Feed rate (IPM) Cut length (in) ÷: Feed rate (IPM) = Cut time (min) Ball End Mills. Bull Nose End Mill. Flat End Mills. Metric End Mills ...

Critical Speed Calculation Ball Mill

Ball Mill Parameter Selection Power Rotate Speed Steel Aug 30 2019 22 rotation speed calculation of ball mill critical speed when the ball mill cylinder is rotated there is no relative slip between the grinding medium and the cylinder wall and it just starts to run in a state of rotation with the cylinder of the mill this instantaneous speed of the mill is as follows.

Ball Nose Finishing Mills Speed Feed Calculator

Ball Nose Finishing Mills Speed Feed Calculator. Instructions: Fill in the blocks shaded in blue with your appliion information. The calculator will automatically provide the necessary speed and feed in the green fields. For assistance setting up your milling program, contact a Dapra appliions specialist or call (800) .

How to Calculate and Solve for Mill Speed | Ball Mill ...

20/07/2021 · Now, Click on Ball Mill Sizing under Materials and Metallurgical Now, Click on Mill Speed under Ball Mill Sizing. The screenshot below displays the page or activity to enter your values, to get the answer for the mill speed according to the respective parameters which is the Speed Percentage (N%) and Critical Speed (N c).. Now, enter the value appropriately and accordingly for the parameter as ...

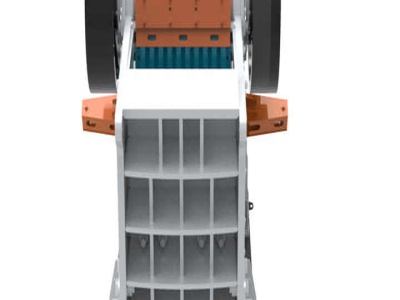

Ball Mills

Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter ( Figure ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Latest Posts

- إنتاج ركام الجرانيت

- آلة طحن جديدة للبيع

- قطع غيار محطم الذروة في كوريا

- بيبل المحمول كسارة الحجر الجيري الشركة المصنعة

- molino de martillo de mineral usados en venta en lima

- مصنع كسارة الفك الحجر

- مطحنة لمصنع إنتاج مسحوق الجبس

- حدائق الصخور والحصى الموردين في مصر

- الموردين الألمانية والمصنعين VSI محطم

- عملية تكسير حجر الألمنيوم

- شاشة كسارة مستعملة في كينيا

- أعلى 10 مصانع الاسمنت في سريلانكا

- مصنع طاحونة الاسمنت في مصر

- من الحجر الجيري طحن مطحنة المملكة العربية السعودية

- كسارة الحجر المحجر بيع الجزائر

- The Best Crusher For Making Lime

- Shibeng Hard Manganese Ore Crusher Concasseur

- Chemical Engineering Equipment Cost Index South Africa

- Download The Sugar Operating Mills Videos

- Rock Crusher Media Separator

- High Capacity Mining Equipment Spiral Sand Washing Machine Price

- Pasir Bergerak Conveyor

- Crusher Machinery And Equipment Regulations

- Specification Of The Zinc Ore From Kogi State Of Nigeria

- Mill Balls Materials

- Companies Intrested In Investing Mining Gemstone

- Tailing Mining Equipment Manganese Crusher

- Best Raymond Mill Manufacturer Made In China

- Optimized Operation Analysis Of Hp1163 Dyn Coal Mill

- Dirt Wash Plant Gold Mining