Saprolite Mineral Processing Grinding

Saprolite

Saprolite (from Greek σαπρος = putrid + λιθος = rock) is a chemically weathered rock (literally, it means "rotten rock"). More intense weathering results in a continuous transition from saprolite to laterite.. Saprolites form in the lower zones of soil horizons and represent deep weathering of the bedrock surface. In lateritic regoliths – regoliths are the loose layer of rocks ...

Process Mineralogy

Process Mineralogy. Process mineralogy encapsulates a number of mineralogyrelated factors of an ore that strongly affect metallurgical performance: Modal mineralogy: How abundant are different mineral species in an orebody? Stoichiometric mineral composition: What is the exact chemical makeup of minerals?

Grinding mills

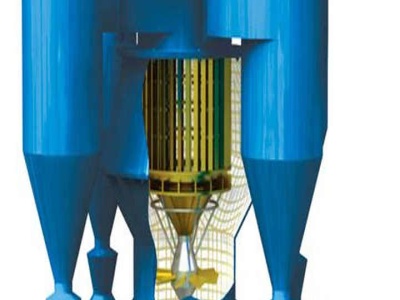

When choosing your equipment we not only keep in mind mill performance, but also considering how your Premier™ or Select™ mill will optimize your minerals processing circuit. Performance Metso Outotec Premier™ mills and Select™ mills are built with a robust design and components to eliminate unplanned downtime leading to high availability and reliability.

Optimization of mill performance by using

grinding media wear rates, throughput, power draw, and product grind size from the circuit. Each of these performance parameters peaks at ... total mineral processing cost. In today's global markets, expanding mining groups are trying to optimize mill performances.

HIGH PRESSURE GRINDING ROLLS—A PROMISING AND COST ...

High pressure grinding rolls were successfully introduced in the cement industry in the late 1980s and enabled appreciable reduction in energy consumption. Promptly enough their potential was realized in mineral mining industry. Strikingly efficient in diamond ore processing, HPGR immediately found appliion there in spite of imperfect ...

Alunite mineral processing grinding mill_Powder mill ...

Alunite mineral processing grinding mill is mainly applied to grind noninflammable, nonexplosive and brittle materials with Mohs' hardness under six. Such as calcite, chalk, limestone, dolomite, kaolin, gypsum, and talc etc, totally more than 100 kinds of materials.

mineral processing saprolite

saprolite mineral processing grinding. Saprolite Mineral Processing Grinding:toff grades of 052g/t for saprolite, 058g/t for saprock, and 062g/t for fresh or, The ore will be processed using a conventional crushing, milling, CIL gold plant ANTAM (Persero) Tbk Nickel Ore MiningANTAM has grinding mills in mineral processing sri lanka grinding mills in mineral processing sri . get price.

Services

Enquire. Molycop offers a full complement of mineral analysis services for gold, platinum group metals, lead, zinc, rare earth, nickel, copper, and lithium commodities, among others. We're continually developing new methods and techniques, creating new equipment and technologies, and rethinking how mineral analysis is performed.

A Study on Classifiion of Limonite and Saprolite from ...

In this study, separation of sparolitetype ore and limonitetype ore from nickel laterite ore from New Caledonia has been tried by dry classifiion. The results show that 5 mm size fraction ...

saprolite mineral processing grinding

saprolite mineral processing grinding [randpic] Saprolite Archives Mineral Processing Metallurgy Solution to the Wet Ore Processing Problem. A washing section is a "must" in all operations handling wet, sticky ore. This facilitates ore handling, crushing, and also affords a

Mineral Processing 101: Tips From Mineral Processing Experts

The process of crushing and grinding is referred to as "comminution" and is the most energyintensive stage of mineral processing. EXPLOITING DIFFERENCES After creating heterogeneity by liberating the valuable minerals from the waste rock, the next step is to separate these particles from one another by exploiting their differences.

Saprolite Archives

Saprolite Crushing and Grinding Wet Sticky Ore In the handling of wet, sticky ores such as encountered in tropical areas having distinct dry and rainy seasons, the crushing plant is a section of the mill which must be planned very carefully.

saprolite mineral processing grinding

Processing Saprolite Gold Ore With Flotation Machine Mining. Saprolite mining goldhindimaster. processing saprolite gold ore with flotation the component of the nigerian mining industries mining equipments for saprolite limonite ores. limonite saprolite goldknowledgecloud technological process of extracting iron oreGold Ore Crusher limonite and saprolite lateritic ores and is

II. IMPORTANCE OF MINERALOGY IN MINERAL PROCESSING

MINERAL PROCESSING Mineral processing technology is evolved to separate and recover ore minerals from gangue in ... Insufficient grinding may result in loss of valuable minerals in the tailings; over grinding wastes energy and may produce slimes that are difficult to treat.

Crushing Vs Grinding

The Difference between Crushing and Grinding in mineral processing Both crushing and grinding are size reduction processes. They are known as milling operations Introduction The size reduction operation in the plant takes place as a sequence of crushing and grinding processes. In crushing, particles are reduced in size to such a level that grinding can ...

Mining Minerals Processing

Crushing Grinding Wet – Magnetic Separation Dry Magnetic Separation Fine Flotation Leaching Classifiion Coarse Flotation LIMS DWD RED RED 2 Eriez is the world authority in separation technology used throughout mineral processing operations. The magnetics division features low, medium and high

Modeling and prediction of wear rate of grinding media in ...

Modeling and prediction of wear rate of grinding media in mineral processing industry using multiple kernel support vector machine Asghar Azizi1 · Reza Rooki2 · Nader Mollayi3 Received: 14 May ... Speed(rpm) Grinding time(min) Wearrate(mpy) 1 8 35 720 12 70 10 2 10 45 360 12 80 10 3 10 35 360 12 70 10 4 10 45 360 12 70 15 ...

Canadian Mineral Processors Examine the Fine Art of Grinding

· Canadian Mineral Processors Examine the Fine Art of Grinding. Insights and clues to unravelling these mysteries were at the top of the list during the 33rd Annual Canadian Mineral Processors Meeting last January in Ottawa. Twelve of the 42 papers on the program were devoted to the fine art of grinding. Here are some of the leading edge ideas ...

MINERAL PROCESSING

MINERAL PROCESSING MILLING Introduction Milling, sometimes also known as fine grinding, pulverising or comminution, is the process of reducing materials to a powder of fine or very fine size. It is distinct from crushing or granulation, which involves size reduction to a rock, pebble or grain size. Milling is used to produce a variety

Saprolite Beneficiation Process

mineral processing saprolite. saprolite beneficiation process. saprolite and low grade nickel ore with a % minimum nickel content Iron Ore Beneficiation,Beneficiation Plant,Flotation,Process Methods. Iron ore beneficiation equipment, magnetic separation, Saprolite gold ores Gold Ore »More detailed. Introduction to Mineral Processing Chevron ...

method for nickel concentration processing of saprolite ore

Basic Knowledge And Mining Technology Ferroalloynet Com. method for nickel concentration processing from saprolite ore thu, jun 2012 gmt. method for nickel concentration processing of saprolite ore. thu, jun 2012 gmt. process for producing stainless steel. thu, jun 2012 gmt. genesis and types of nickel laterites. wed, jun 2012 gmt

Latest Posts

- عملية تكسير السيليكا

- طاحونة موزع dynomill عمان

- تقرير المشروع على كسارة الحجارة الصغيرة

- كيف يعمل منجم المحجر

- البريليوم الفك محطم

- كسارة حجر الفك محطم رخيصة

- كسارة تعدين الفحم cak

- معدات تكسير الصخور العراق

- معمل تكسير وغسل الفحم بيع مصر

- sbm محطة معالجة خام الذهب الصغيرة

- خام الحديد محطة إثراء الأنابيب

- آلة تكسير التبغ

- يصادف كسارة ثابتة

- 4 25 كسارات مخروطية حجرية للبيع في مصر

- مطحنة الكرة تعدين الذهب بقدرة عالية

- Underground Mining Scooptram Underground Mining Screening

- Designing A Glass Crushing Machine

- Block Diagram Of Aluminium Extraction

- Zenith Copper Ore Crusher And Grinder In Zimbabwe

- Sugar Mill Setup Cost Pakistan

- Calculator All Valley Sand And Gravel Inc

- Crusher Reqd For Crushing From Mm To Mm

- Buy Ball Jar Mill

- Pop Grinding Mill Zenith Mtm Trapezium Mill

- Crusher Schematic Crushergranite

- Georg Grinding Machine Stainless Steel

- Tunisia Crushing Screening Equipment Import E Port Companies

- Large Industrial Ball Mill Australia For Sale

- Davis Tube Magnetic Separator For Sale

- Big Bazar Small Grinder