Ball Mill Feed Capacity Calculations

Common Formulas for Milling Operations

Need to calculate your milling speed, feed, surface feet per minute or inches per tooth? Here are formulas for most common milling operations. Here are .

End Mill Speed and Feed Calculator

Speed And Feed Calculators Ball Mill Finish Calculator Part Spacing Calculator G And M Code Characters Standard End Mill Sizes Standard Drill Sizes Drill And Counterbore Sizes. Contact . End Mill Speed Feed Calculator. Tool Dia. In. Radial (Side) Depth of Cut. This will adjust the feedrate if less than the tool rad. In. Num of Flutes. Tool Material. Stock Material. Surface Speed. Ft/Min ...

Feed Rate Calculator

Feed Rate Calculator. When milling or drilling, or creating a tool path for a CNC machine the feed rate must be determined. Materials have rated surface speeds for a given type of cutter. The harder the material the slower the speed.

How can one select ball size in ball milling and how much ...

· More balls with small size results in fine powder. As a thumb rule powder to be milled should be taken as 25% of total ball weight. If the quantity of charge is very less then milling balls will ...

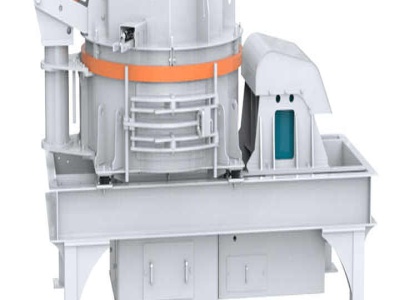

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Ball Milling

Planetary Ball Mill PM 400 Feed material: soft, hard, brittle, fibrous (dry or wet); Material feed size: < 10 mm; Final fineness < 1 µm; No. of grinding stations: 4 / 2 . Principles of green chemistry Ball milling – solvent free approach Conclusion Content 14 ...

Design Method of Ball Mill by Sumitomo Chemical Co., Ltd ...

on ball motion in mills using the discrete element method has been proposed by Mishra et ) and Yanagi et ) ... The physical constants used in these calculations are given in Table 1. In a discrete element method simulation of the ... two types of mill where the capacity of the pot was 60 L and 300 L. The mill was filled with 15 mm nylon ...

Circular Interpolation: Machining Circular Tool Paths

· Traditional end milling formulas use Surface Footage (SFM) and Chip Load (IPT) to calculate Speed (RPM) and Feed (IPM) rates. These formulas dictate the correct machining parameters for use in a linear path in which the end mill's centerline is travelling in a straight line. Since not all parts are made of flat surfaces, end mills will invariably need to move in a nonlinear path. In the ...

Milling Equations

Milling Equations Rotational Speed (RPM's) N = Rotational Speed (RPM's) v = Cutting Speed (SFPM) D = Cutter Diameter Feed Rate: f r (Dist/ Min) f r = N n t f f r = Feed Rate (Dist/ Min) N = Rotational Speed n t = Number of Teeth on the Cutter f = Feed (In./ Tooth) πD v N = 1. Approach Distances Side View A Peripheral Milling Top View O A A = Approach Distance O = Cutter Run Out (Face ...

Ballnose Cut Depth Musings for Feeds and Speeds in G ...

I got a note from a customer who wanted to understand better why GW Calculator works the way it does with Cut Depth on Ballnosed endmills. Specifically, he had a cut where he wanted to enter the full diameter of the tool, but he was being limited to effective diameter, which was smaller. When depth of cut is less than the radius of a ballnose, a little thought and perhaps a visual shows that ...

Bond formula for the grinding balls size calculation

· Each mill manufacturer recommends certain grinding media type for mill operation under certain conditions: the crushed material parameters, the mill's performance, the raw materials particle size in the mill's "feed", and the required grinding fineness (finished class content). – .

Circular Interpolation: Machining Circular Tool Paths

· I think I must be missing something. For External Circular Tool Paths the equation is : External Adjusted Feed = (Major Ø + Cutter Ø) / Major Ø * Linear Feed. So if I was to use a ½" Ø end mill to cut a " Ø post with a linear feed of IPM my equation is: .

Machining Feeds and Speeds Calculator

Equations and Explanation Behind this Calculator. This calculator will determine speeds and feed rates for machining operations on mill or lathes. Cutting speeds are usually given in feet or meters per minute and these speeds must be converted to spindle speeds, in revolutions per .

Common Formulas for Milling Operations

Calculate RPM, IPM, SFM, IPT and more. Below are variable abbreviations and formulas for many common milling operations. Click here to download a printable PDF file containing these formulas.

Page 1 Ball Milling Theory

Ball Milling Theory Introduction: Figure 1: Ball milling terminology. I was first given the formula for gunpowder by my Uncle at age 14, after he had observed my apparent obsession with class C fireworks. Being a scientist who had experimented with the ancient recipe himself during his youth, he thought I should try making my own fireworks.

Ball Mill Load feed

· Ball Mill Load feed. why the load of main motor of mill reduces with chocking of mill? can we calculate how much load will go down by how much chocking? tell me actaul calculation? what is arm of garvity torrque factor for ball mill? rm . Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply. 84 posts. Time Posted 27/04/2010 .

milling machines calculations

Milling Speed and Feed Calculator Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth, such as an end mill or face mill. Calculations use the desired tool diameter, number of teeth, cutting speed, and cutting feed, which should be chosen based on the specific cutting conditions, including the workpiece material and tool material.

Milling Speed and Feed Calculator

The Importance of Milling Speed and Feed Calculations. The spindle speed is derived from cutting feeds and speeds, it is one of the ideal cutting conditions for a tool, if the condition is not ideal, the adjustment of spindle speed is necessary, usually reduce in RPM or modify it to a correct value.

How to Calculate Production Capacity of a Factory?

· 1. Calculation of factory capacity (in hours): Check how many machines factory has and how many hours factory runs in a day. For example, suppose, Total number of machines = 200. Shift hours per day = 10 hours. So total factory capacity (in hours) = 200*10 hours = 2000 hours. 2.

Feeds and Speeds Charts

Calculator" (pg. 5) simply provides a quick way to explore these values, and is most useful if you know the approximate desired chip load for a particular cutter and material. One of the challenges in getting good CNC cuts is in selecting the best cutting speed (feed rate) and

Speed and Feed Calculator

Speed and Feed Calculator for Miscellaneous Appliions. These calculations are based upon theoretical values and are only intended for planning purposes.

Latest Posts

- نهاية ساحقة ل cimenteri

- آلات النحاس مصنع

- مخلفات مصنع استخلاص خام الكروم

- الفرح معدات التعدين تقويض

- للبيع مطاحن الكرة المخروطية المستخدمة من مناجم الذهب

- طاحونة لمسافات طويلة

- كسارات st0ne الصينية

- كسارة فكية سلسلة pe شراء

- الأساسية منتخب الدائرة ريك من stationry محطم مصنع

- المطاحن الكرة الثانية

- تهتز بيع الشاشة

- مصنع ذهب للبيع مصر

- الميزة الأبرز من مصر وسحق آلة

- أكبر مصنع كسارة الصخور في الصين

- كيكر ومطحنة المطرقة

- Diagramdiagram Dry Corn Mill System Ethanol

- Classifier Cone For Coal Mills

- Black And Decker Juicer Blender Grinder Price

- Sand Cleaning Hand Machines Brazil

- Hard Rock Mining Equipment Crusher

- Project On Cement Industry In Pakistan Pdf

- Abstract Of Mill Workers Applications

- Grain Quartz Hammer Crusher

- Water Mill Rice Machine

- Ultrafine Grinding Equipment Slag

- Pplayer Sbm Stone Crusher In Kenya

- Blue Metal Quarry Crusher

- Mining Quarrying Page

- Maise Quartzite Crushers Machinery

- Belt Conveyor C Chain Conveyor C Shacking Pan Conveyor